2-苯基-1,2-环氧丙烷 | 2085-88-3

中文名称

2-苯基-1,2-环氧丙烷

中文别名

2-甲基-2-苯基环氧乙烷;2-苯基氧化丙烯;2-苯基环氧丙烷

英文名称

2-methyl-2-phenyloxirane

英文别名

α-methylstyrene oxide;2-phenylpropylene oxide;α-methylstyrene epoxide;1,2-epoxy-2-phenylpropane;2-phenyl-1,2-epoxypropane;(1,2-epoxy-1-methylethyl)-benzene

CAS

2085-88-3

化学式

C9H10O

mdl

MFCD00059156

分子量

134.178

InChiKey

MRXPNWXSFCODDY-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:82 °C / 14mmHg

-

密度:1,02 g/cm3

-

闪点:68°C

-

保留指数:1665.5;1666.3

计算性质

-

辛醇/水分配系数(LogP):1.6

-

重原子数:10

-

可旋转键数:1

-

环数:2.0

-

sp3杂化的碳原子比例:0.333

-

拓扑面积:12.5

-

氢给体数:0

-

氢受体数:1

安全信息

-

安全说明:S26,S36/37/39

-

危险类别码:R36/37/38

-

海关编码:2910900090

-

储存条件:室温

SDS

Section I.Chemical Product and Company Identification

Chemical Name 2-Phenylpropylene Oxide

Portland OR

Synonym 1,2-Epoxy-2-phenylpropane

Chemical Formula C9H10O

CAS Number 2085-88-3

Section II. Composition and Information on Ingredients

Chemical Name CAS Number Percent (%) TLV/PEL Toxicology Data

2-Phenylpropylene Oxide 2085-88-3 ----------- Not available. Not available.

Section III. Hazards Identification

Acute Health Effects No specific information is available in our data base regarding the toxic effects of this material for humans. However,

exposure to any chemical should be kept to a minimum. Skin and eye contact may result in irritation. May be harmful if

inhaled or ingested. Always follow safe industrial hygiene practices and wear proper protective equipment when handling

this compound.

CARCINOGENIC EFFECTS : Not available.

Chronic Health Effects

MUTAGENIC EFFECTS : Not available.

TERATOGENIC EFFECTS : Not available.

DEVELOPMENTAL TOXICITY: Not available.

There is no known effect from chronic exposure to this product. Repeated or prolonged exposure to this compound is

not known to aggravate existing medical conditions.

Section IV. First Aid Measures

Eye Contact Check for and remove any contact lenses. DO NOT use an eye ointment. Flush eyes with running water for a minimum

of 15 minutes, occasionally lifting the upper and lower eyelids. Seek medical attention. Treat symptomatically and

supportively.

Skin Contact After contact with skin, wash immediately with plenty of water. Gently and thoroughly wash the contaminated skin with

running water and non-abrasive soap. Be particularly careful to clean folds, crevices, creases and groin. Cover the

irritated skin with an emollient. Seek medical attention. Treat symptomatically and supportively. Wash any contaminated

clothing before reusing.

Inhalation If the victim is not breathing, perform artificial respiration. Loosen tight clothing such as a collar, tie, belt or waistband. If

breathing is difficult, oxygen can be administered. Seek medical attention. Treat symptomatically and supportively.

Ingestion INDUCE VOMITING by sticking finger in throat. Lower the head so that the vomit will not reenter the mouth and throat.

Loosen tight clothing such as a collar, tie, belt, or waistband. If the victim is not breathing, administer artificial respiration.

Examine the lips and mouth to ascertain whether the tissues are damaged, a possible indication that the toxic material

was ingested; the absence of such signs, however, is not conclusive. Seek immediate medical attention and, if possible,

show the chemical label. Treat symptomatically and supportively.

Section V. Fire and Explosion Data

Auto-Ignition Not available.

Flammability Combustible.

Flash Points Flammable Limits Not available.

68°C (154.4°F).

Combustion Products These products are toxic carbon oxides (CO, CO 2).

Fire Hazards

No specific information is available regarding the flammability of this compound in the presence of various materials.

Explosion Hazards Risks of explosion of the product in presence of mechanical impact: Not available.

Risks of explosion of the product in presence of static discharge: Not available.

No additional information is available regarding the risks of explosion.

Fire Fighting Media

SMALL FIRE: Use DRY chemicals, CO 2, water spray or foam.

and Instructions LARGE FIRE: Use water spray, fog or foam. DO NOT use water jet.

Continued on Next Page

2-Phenylpropylene Oxide

Section VI. Accidental Release Measures

Spill Cleanup Keep away from heat and sources of ignition. Mechanical exhaust required. Stop leak if without risk. Finish cleaning the

Instructions spill by rinsing any contaminated surfaces with copious amounts of water. Consult federal, state, and/or local authorities

for assistance on disposal.

Section VII. Handling and Storage

Handling and Storage Keep away from heat and sources of ignition. Mechanical exhaust required. When not in use, tightly seal the container

and store in a dry, cool place. Avoid excessive heat and light. Do not breathe gas, fumes, vapor or spray. In case of

Information

insufficient ventilation, wear suitable respiratory equipment. If you feel unwell, seek medical attention and show the label

when possible. Treat symptomatically and supportively. Avoid contact with skin and eyes.

Always store away from incompatible compounds such as oxidizing agents.

Section VIII. Exposure Controls/Personal Protection

Engineering Controls Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their

respective threshold limit value. Ensure that eyewash station and safety shower is proximal to the work-station location.

Personal Protection Splash goggles. Lab coat. Vapor respirator. Boots. Gloves. A MSHA/NIOSH approved respirator must be used to avoid

inhalation of the product. Suggested protective clothing might not be sufficient; consult a specialist BEFORE handling

this product.

Exposure Limits Not available.

Section IX. Physical and Chemical Properties

Physical state @ 20°C Liquid. Solubility

Not available.

1.02

Specific Gravity

Molecular Weight 134.18 Partition Coefficient

Not available.

Boiling Point 43°C (109.4°F) Vapor Pressure Not available.

Melting Point Not available. Vapor Density Not available.

Not available. Not available.

Refractive Index Volatility

Critical Temperature Not available. Odor Not available.

Viscosity Not available. Taste Not available.

Section X. Stability and Reactivity Data

Stability

This material is stable if stored under proper conditions. (See Section VII for instructions)

Conditions of Instability

Avoid excessive heat and light.

Incompatibilities

Reactive with oxidizing agents.

Section XI. Toxicological Information

RTECS Number RR0532400

Routes of Exposure Eye contact. Inhalation. Ingestion.

Not available.

Toxicity Data

CARCINOGENIC EFFECTS : Not available.

Chronic Toxic Effects

MUTAGENIC EFFECTS : Not available.

TERATOGENIC EFFECTS : Not available.

DEVELOPMENTAL TOXICITY: Not available.

There is no known effect from chronic exposure to this product. Repeated or prolonged exposure to this compound is not

known to aggravate existing medical conditions.

Acute Toxic Effects No specific information is available in our data base regarding the toxic effects of this material for humans. However,

exposure to any chemical should be kept to a minimum. Skin and eye contact may result in irritation. May be harmful if

inhaled or ingested. Always follow safe industrial hygiene practices and wear proper protective equipment when handling

this compound.

Continued on Next Page

2-Phenylpropylene Oxide

Section XII. Ecological Information

Ecotoxicity Not available.

Environmental Fate Not available.

Section XIII. Disposal Considerations

Recycle to process, if possible. Consult your local or regional authorities. You may be able to dissolve or mix material with

Waste Disposal

a combustible solvent and burn in a chemical incinerator equipped with an afterburner and scrubber system. Observe all

federal, state, and local regulations when disposing of this substance.

Section XIV. Transport Information

DOT Classification Not a DOT controlled material (United States).

PIN Number Not applicable.

Proper Shipping Name

Not applicable.

Packing Group (PG) Not applicable.

DOT Pictograms

Section XV. Other Regulatory Information and Pictograms

TSCA Chemical Inventory This product is NOT on the EPA Toxic Substances Control Act (TSCA) inventory. The following notices are required by 40

CFR 720.36 (C) for those products not on the inventory list:

(EPA)

(i) These products are supplied solely for use in research and development by or under the supervision of a technically

qualified individual as defined in 40 CFR 720.0 et sec.

(ii) The health risks of these products have not been fully determined. Any information that is or becomes available will be

supplied on an MSDS sheet.

WHMIS Classification Not available.

(Canada)

EINECS Number (EEC) Not available.

EEC Risk Statements Not available.

SECTION 16 - ADDITIONAL INFORMATION

N/A

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 2-苯基-1,2-丙二醇 1,2-dihydroxy-2-phenylpropane 4217-66-7 C9H12O2 152.193 氧化苯乙烯 styrene oxide 96-09-3 C8H8O 120.151 2-苯基-2-丙醇 1-methyl-1-phenylethyl alcohol 617-94-7 C9H12O 136.194 —— 2-Bromo-α-methylstyrene Oxide 71095-28-8 C9H9BrO 213.074 —— 3-methyl-3-phenyloxirane-2-carbaldehyde 1189774-61-5 C10H10O2 162.188 1-碘-2-苯基-2-甲基-2-乙醇 1-iodo-2-phenylpropan-2-ol 60212-12-6 C9H11IO 262.09 —— 3-methyl-3-phenyl-1,2-dioxetane 35322-45-3 C9H10O2 150.177 —— 1-bromo-2-phenylpropan-2-ol 31778-29-7 C9H11BrO 215.09 —— 1-chloro-2-phenylpropan-2-ol 15561-33-8 C9H11ClO 170.639 -

下游产品

中文名称 英文名称 CAS号 化学式 分子量 (2R)-2-甲基-2-苯基环氧乙烷 (R)-2-methyl-2-phenyloxirane 21019-52-3 C9H10O 134.178 (2S)-2-甲基-2-苯基环氧乙烷 (2S)-2-methyl-2-phenyloxirane 2404-43-5 C9H10O 134.178 2-甲氧基-2-苯基丙烷-1-醇 2-methoxy-2-phenylpropanol 69160-04-9 C10H14O2 166.22 2-苯基-1,2-丙二醇 1,2-dihydroxy-2-phenylpropane 4217-66-7 C9H12O2 152.193 —— (2S)-2-phenylpropane-1,2-diol 2406-22-6 C9H12O2 152.193 —— (R)-1-phenyl-1,2-ethanediol —— C9H12O2 152.193 2-苯基-2-丙醇 1-methyl-1-phenylethyl alcohol 617-94-7 C9H12O 136.194 —— 2-tert-butoxy-2-phenylpropan-1-ol 853990-41-7 C13H20O2 208.301 —— 2-hydroperoxy-2-phenyl-1-propanol 33334-31-5 C9H12O3 168.192 2-苯基-1-丙醇 (RS)-2-phenyl-1-propanol 1123-85-9 C9H12O 136.194 (S)-2-苯基-1-丙醇 (S)-2-phenyl-1-propanol 37778-99-7 C9H12O 136.194 (R)-(+)-2-苯基-1-丙醇 (+)-(R)-2-phenylpropanol 19141-40-3 C9H12O 136.194 2-苯基-2-丁醇 2-phenyl-2-butanol 1565-75-9 C10H14O 150.221 —— 1-mercapto-2-phenyl-propan-2-ol 88224-84-4 C9H12OS 168.26 1-氨基-2-苯基-2-丙醇 (+/-)-1-amino-2-phenylpropan-2-ol 17643-24-2 C9H13NO 151.208 —— 2-phenylbut-3-en-2-ol 6051-52-1 C10H12O 148.205 —— (+/-)-1-acetoxy-2-phenyl-2-propanol 72331-76-1 C11H14O3 194.23 —— 1-hydroxy-2-(tert-butylperoxy)-α-methyl-(1-phenyl)ethane —— C13H20O3 224.3 —— 1-chloro-2-phenylpropan-2-ol 15561-33-8 C9H11ClO 170.639 —— 1-bromo-2-phenylpropan-2-ol 31778-29-7 C9H11BrO 215.09 2-甲基-2-苯基丙烷-1-醇 2-methyl-2-phenyl-propan-1-ol 2173-69-5 C10H14O 150.221 —— (2R)-2-methyl-2-phenyloxetane 1146489-93-1 C10H12O 148.205 —— 2-methyl-2-phenyloxetane 19352-10-4 C10H12O 148.205 - 1

- 2

- 3

反应信息

-

作为反应物:描述:参考文献:名称:通过选择性 CO 键活化环氧化物的区域发散性硼氢化环开环摘要:提出了镁催化的区域发散 C-O 键裂解方案。容易获得的镁催化剂实现了多种环氧化物和氧杂环丁烷的选择性硼氢化反应,以优异的产率和区域选择性得到仲醇和叔醇。实验机理研究和 DFT 计算提供了对意外区域发散的洞察,并解释了 C-O 键活化和产物形成的不同机制。DOI:10.1021/jacs.0c05917

-

作为产物:描述:2-苯基-1-丙烯 在 sodium periodate 作用下, 以 水 、 乙腈 为溶剂, 20.0 ℃ 、101.33 kPa 条件下, 反应 0.25h, 以78%的产率得到2-苯基-1,2-环氧丙烷参考文献:名称:固定在羧化多壁碳纳米管上的高效且可重复使用的钌萨洛芬催化剂,用于高碘酸钠环氧化碳氢化合物摘要:本研究以含有羧酸基团的多壁碳纳米管为载体,用 1,4-二氨基苯、4-氨基苯酚和 4-氨基吡啶改性,并通过轴向配位将 Ru(salophen)Cl 配合物连接到这些载体上。 . 这些催化剂通过元素分析、UV-vis、FT-IR 和 SEM 等不同技术进行了表征。然后,这些非均相催化剂在磁力搅拌和超声辐照条件下用于烯烃的环氧化。各种供氧体如高碘酸钠、过氧化氢、叔考察了过氧化氢丁基、高碘酸四丁基铵、次氯酸钠以及乙腈、丙酮、甲醇、乙醇、氯仿、二氯甲烷等不同溶剂对产物收率的影响。结果表明,这些非均相催化剂在环氧化反应中是有效且可重复使用的。DOI:10.1007/s13738-022-02553-4

-

作为试剂:描述:参考文献:名称:一种制备3-甲基-2-丁烯醇的方法摘要:本发明提供一种由3‑甲基‑3‑丁烯醇异构制备3‑甲基‑2‑丁烯醇(异戊烯醇)的方法。催化剂反应体系包含:1)羰基铁化合物;2)有机碱;3)环氧基配体。异构化反应中加入具有醚类结构的溶剂能够提高催化剂活性,提高产物选择性。在催化过程及分离中通入一氧化碳(CO)与氮气(N2)的混合气,其中CO的体积含量为100ppm‑100000ppm。催化剂和原料3‑甲基‑3‑丁烯醇通过精馏方式与产物异戊烯醇分离,不需额外分离催化剂。催化剂保持高活性、长寿命运行。公开号:CN107141197B

文献信息

-

1,1,2,2-Tetrahydroperoxy-1,2-Diphenylethane: An efficient and high oxygen content oxidant in various oxidative reactions作者:Kaveh Khosravi、Shirin NaserifarDOI:10.1016/j.tet.2018.09.041日期:2018.11Several oxidative approaches namely thiocyanation of aromatic compounds, epoxidation of alkenes, amidation of aromatic aldehydes, epoxidation of α, β-unsaturated ketones, oxidation of sulfides to sulfoxides and sulfones, bayer-villeger reaction, bromination and iodation of aniline and phenol derivatives oxidative esterification, oxidation of pyridines and oxidation of secondary, allylic and benzyllic

-

Spectroscopy and catalytic activity study of gold supported on barium titanate nanotubes for styrene epoxidation作者:Devadutta Nepak、Darbha SrinivasDOI:10.1016/j.apcata.2016.05.014日期:2016.85–5 wt.%) supported on barium titanate nanotubes (Au/BaTNT) were prepared, characterized and for the first time, investigated as catalysts for selective oxidation of styrene with oxygen (O2 or H2 + O2) and peroxides (H2O2 or TBHP). Conversion of styrene enhanced when H2 was co-added to O2 in the reactions. Au/BaTNT activated O2 and H2 and produced H2O2 in situ for use in oxidations. Peroxides were found制备了负载在钛酸钡纳米管(Au / BaTNT)上的金(0.5-5 wt。%),并进行了表征,并首次进行了研究,将其用作用氧气(O 2或H 2 + O 2)和苯乙烯选择性氧化的催化剂。过氧化物(H 2 O 2或TBHP)。当在反应中将H 2共添加到O 2中时,苯乙烯的转化率提高。Au / BaTNT活化O 2和H 2并原位产生H 2 O 2 用于氧化。发现过氧化物比O 2更好的氧化剂。在最佳条件下,使用TBHP相对于Au(1 wt%)/ BaTNT,苯乙烯转化率为60.5 wt。%时,苯乙烯氧化物的选择性达到80.1 wt。%。金粒子(5.0–7.4 nm)分散并装饰在BaTNT的壁上。在苯乙烯氧化中,它们表现出优于已知Au催化剂的性能。在氧化反应过程中形成的活性氧具有原位光谱特征(漫反射紫外可见和傅立叶拉曼光谱)。Au / BaTNT可在四个循环中重复使用,催化活性几乎没有损失。

-

Zinc(<scp>II</scp>)-catalysed transformation of epoxides to aziridines作者:Dorte Kühnau、Ib Thomsen、Karl Anker JørgensenDOI:10.1039/p19960001167日期:——The Lewis acid-catalysed transformation of epoxides to aziridines with iminophosphoranes as the nitrogen-fragment donor has been investigated. Of the Lewis acids tested, zinc(II) complexes had the best catalytic properties. The method works best for terminal and cyclic epoxides, internal epoxides being less reactive. Of the various iminophosphoranes employed N-(triphenylphosphoranylidene)-aniline and

-

Kinetics of C–H bond and alkene oxidation by trans-dioxoruthenium(<scp>VI</scp>) porphyrins作者:Clare Ho、Wa-Hung Leung、Chi-Ming CheDOI:10.1039/dt9910002933日期:——characterized, and the kinetics and mechanism of oxidation of the C–H bond and alkenes investigated. The complexes were selective towards tertiary C–H bonds in saturated alkanes but were almost inactive towards secondary C–H bonds. However, they were reactive towards aromatic hydrocarbons and the second-order rate constants (k2) for the oxidation of ethylbenzene and cumene by [Ru(tpp)O2](tpp = 5, 10, 15, 20-teA.合成并表征了一系列[Ru VI LO 2 ]配合物(H 2 L =对位取代的四苯基卟啉),并研究了C–H键和烯烃的氧化动力学和机理。该络合物对饱和烷烃中的C–H键具有选择性,但对C–H二级键几乎没有活性。但是,它们对芳烃有反应性,[Ru(tpp)O 2 ](tpp = 5,10,15,20-四苯基卟啉)氧化乙苯和枯烯的二级速率常数(k 2)为2.21。 ×10 –4和3.16×10 –4 dm 3 mol –1s –1分别。发现环己烯被[Ru(tpp)O 2 ]烯丙基氧化的动力学同位素效应(K H / K D)为11.7 。CH 2 Cl 2 -MeOH混合物中烯烃氧化的主要有机产物是环氧化物,[Ru(tpp)O 2 ]得到的单体产物为[Ru IV(tpp)O]·EtOH。或[Ru IV(tpp)(OH)2 ·] EtOH。与[Ru VI(oep)O 2 ](oep = 2,3,7,8

-

Mild Iridium‐Catalysed Isomerization of Epoxides. Computational Insights and Application to the Synthesis of β‐Alkyl Amines作者:Albert Cabré、Juanjo Cabezas‐Giménez、Giuseppe Sciortino、Gregori Ujaque、Xavier Verdaguer、Agustí Lledós、Antoni RieraDOI:10.1002/adsc.201900372日期:2019.8.5The isomerization of epoxides to aldehydes using the readily available Crabtree's reagent is described. The aldehydes were transformed into synthetically useful amines by a one‐pot reductive amination using pyrrolidine as imine‐formation catalyst. The reactions worked with low catalyst loadings in very mild conditions. The procedure is operationally simple and tolerates a wide range of functional groups

表征谱图

-

氢谱1HNMR

-

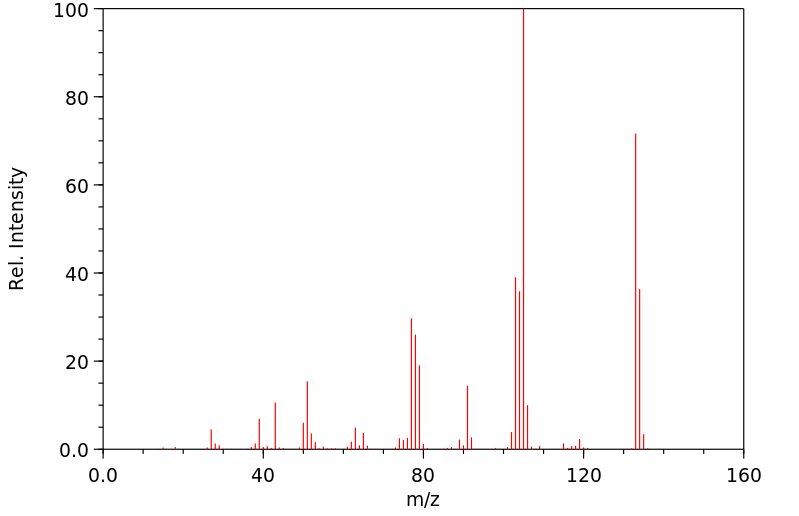

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(βS)-β-氨基-4-(4-羟基苯氧基)-3,5-二碘苯甲丙醇

(S,S)-邻甲苯基-DIPAMP

(S)-(-)-7'-〔4(S)-(苄基)恶唑-2-基]-7-二(3,5-二-叔丁基苯基)膦基-2,2',3,3'-四氢-1,1-螺二氢茚

(S)-盐酸沙丁胺醇

(S)-3-(叔丁基)-4-(2,6-二甲氧基苯基)-2,3-二氢苯并[d][1,3]氧磷杂环戊二烯

(S)-2,2'-双[双(3,5-三氟甲基苯基)膦基]-4,4',6,6'-四甲氧基联苯

(S)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(R)富马酸托特罗定

(R)-(-)-盐酸尼古地平

(R)-(-)-4,12-双(二苯基膦基)[2.2]对环芳烷(1,5环辛二烯)铑(I)四氟硼酸盐

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[((6-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(4-叔丁基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(3-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-4,7-双(3,5-二-叔丁基苯基)膦基-7“-[(吡啶-2-基甲基)氨基]-2,2”,3,3'-四氢1,1'-螺二茚满

(R)-3-(叔丁基)-4-(2,6-二苯氧基苯基)-2,3-二氢苯并[d][1,3]氧杂磷杂环戊烯

(R)-2-[((二苯基膦基)甲基]吡咯烷

(R)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(N-(4-甲氧基苯基)-N-甲基-3-(1-哌啶基)丙-2-烯酰胺)

(5-溴-2-羟基苯基)-4-氯苯甲酮

(5-溴-2-氯苯基)(4-羟基苯基)甲酮

(5-氧代-3-苯基-2,5-二氢-1,2,3,4-oxatriazol-3-鎓)

(4S,5R)-4-甲基-5-苯基-1,2,3-氧代噻唑烷-2,2-二氧化物-3-羧酸叔丁酯

(4S,4''S)-2,2''-亚环戊基双[4,5-二氢-4-(苯甲基)恶唑]

(4-溴苯基)-[2-氟-4-[6-[甲基(丙-2-烯基)氨基]己氧基]苯基]甲酮

(4-丁氧基苯甲基)三苯基溴化磷

(3aR,8aR)-(-)-4,4,8,8-四(3,5-二甲基苯基)四氢-2,2-二甲基-6-苯基-1,3-二氧戊环[4,5-e]二恶唑磷

(3aR,6aS)-5-氧代六氢环戊基[c]吡咯-2(1H)-羧酸酯

(2Z)-3-[[(4-氯苯基)氨基]-2-氰基丙烯酸乙酯

(2S,3S,5S)-5-(叔丁氧基甲酰氨基)-2-(N-5-噻唑基-甲氧羰基)氨基-1,6-二苯基-3-羟基己烷

(2S,2''S,3S,3''S)-3,3''-二叔丁基-4,4''-双(2,6-二甲氧基苯基)-2,2'',3,3''-四氢-2,2''-联苯并[d][1,3]氧杂磷杂戊环

(2S)-(-)-2-{[[[[3,5-双(氟代甲基)苯基]氨基]硫代甲基]氨基}-N-(二苯基甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[((1S,2S)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[[((1R,2R)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2-硝基苯基)磷酸三酰胺

(2,6-二氯苯基)乙酰氯

(2,3-二甲氧基-5-甲基苯基)硼酸

(1S,2S,3S,5S)-5-叠氮基-3-(苯基甲氧基)-2-[(苯基甲氧基)甲基]环戊醇

(1S,2S,3R,5R)-2-(苄氧基)甲基-6-氧杂双环[3.1.0]己-3-醇

(1-(4-氟苯基)环丙基)甲胺盐酸盐

(1-(3-溴苯基)环丁基)甲胺盐酸盐

(1-(2-氯苯基)环丁基)甲胺盐酸盐

(1-(2-氟苯基)环丙基)甲胺盐酸盐

(1-(2,6-二氟苯基)环丙基)甲胺盐酸盐

(-)-去甲基西布曲明

龙蒿油

龙胆酸钠

龙胆酸叔丁酯

龙胆酸

龙胆紫-d6

龙胆紫