5-甲基-2-(1-甲基乙基)-2-环己烯-1-酮 | 5113-66-6

中文名称

5-甲基-2-(1-甲基乙基)-2-环己烯-1-酮

中文别名

——

英文名称

2-isopropyl-5-methyl-2-cyclohexen-1-one

英文别名

p-menth-4-en-3-one;5-methyl-2-(1-methylethyl)-2-cyclohexen-1-one;Menthenon;2-Cyclohexen-1-one, 5-methyl-2-(1-methylethyl)-;5-methyl-2-propan-2-ylcyclohex-2-en-1-one

CAS

5113-66-6

化学式

C10H16O

mdl

——

分子量

152.236

InChiKey

OAYBZGPDRAMDNF-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:213-214 °C

-

密度:0.9222 g/cm3

-

保留指数:1251;1251

-

稳定性/保质期:

存在于主流烟气中。

计算性质

-

辛醇/水分配系数(LogP):2.5

-

重原子数:11

-

可旋转键数:1

-

环数:1.0

-

sp3杂化的碳原子比例:0.7

-

拓扑面积:17.1

-

氢给体数:0

-

氢受体数:1

安全信息

-

海关编码:2914299000

SDS

上下游信息

反应信息

-

作为反应物:描述:5-甲基-2-(1-甲基乙基)-2-环己烯-1-酮 生成 menthol参考文献:名称:Wallach; Meister, Justus Liebigs Annalen der Chemie, 1908, vol. 362, p. 276摘要:DOI:

-

作为产物:描述:参考文献:名称:Synthesis of optically active triazolinediones and examination of their utility for inducing asymmetry in Diels-Alder cycloaddition reactions摘要:DOI:10.1021/jo01313a018

文献信息

-

[EN] CONJUGATED DIENE PHOSPHINATE COMPOUNDS, PREPARATION METHOD AND USE THEREOF<br/>[FR] COMPOSÉS PHOSPHINATE DE DIÈNE CONJUGUÉ, LEUR PROCÉDÉ DE PRÉPARATION ET LEUR UTILISATION申请人:RHODIA CHINA CO LTD公开号:WO2011050537A1公开(公告)日:2011-05-05This invention relates to conjugated diene phosphinate compounds for making halogen free phosphinate-containing flame retardants, inimer and metal extractants, method for preparing said compounds from unsaturated ketones or aldehydes, and the 5 use thereof. The compounds of the present invention having the following formula (III), wherein R 1, R 2, R 3, R 4, R 5 and R 6 represent, independently, hydrogen, alkyl, aryl, alkaryl, aralkyl, cycloalkyl, heterocycloalkyl, or alkenyl groups; R 7 represents hydrogen, alkyl, aryl, alkaryl, aralkyl, cycloalkyl, alkenyl groups, or metals selected from the group consisting of Na, Li, Ca.

-

[EN] METHOD FOR PREPARING CONJUGATED DIENE PHOSPHONATE COMPOUNDS<br/>[FR] PROCÉDÉ DE PRÉPARATION DE COMPOSÉS PHOSPHONATE DE DIÈNE CONJUGUÉ申请人:RHODIA CHINA CO LTD公开号:WO2011050533A1公开(公告)日:2011-05-05It is provided a method for preparing conjugated diene phosphonate compounds with high reactivity, which can be used to prepare a variety of phosphonate-bearing conjugated dienes. Some of those dienes will become reactive monomers to make polymers and co-polymers. The said method comprises the step of reacting α, β- or β, γ- unsaturated ketones or aldehydes with phosphorous acid or its derivates optionally in a mixture of acetic anhydride and/or acetic acid, to obtain a conjugated diene phosphonate compound having the formula (III)

-

Oxidation of Terpene Compounds with tert-Butyl Chromate. VII. Oxidation of<i>d</i>-<i>p</i>-Menthene-3作者:Kozo FujitaDOI:10.1246/bcsj.34.968日期:1961.7In this oxidation, it is found that, when an endocyclic double bond is in the position between C(3) and C(4) in monocyclic terpenes of p-menthane type, two active methylenes adjacent to the endocyclic double bond are selectively oxidized to carbonyls as in the case of the terpenes containing an endocyclic double bond in the position between C(1) and C(2), and that, between the two active methylenes,

-

METHOD OF MANUFACTURING 4,4"-DIHYDROXY-M-TERPHENYL申请人:Honshu Chemical Industry Co., Ltd.公开号:US20150158800A1公开(公告)日:2015-06-11To achieve the object of providing a new method of manufacturing 4,4″-dihydroxy-m-terphenyl, the present invention provides a method of manufacturing 4,4″-dihydroxy-m-terphenyl expressed by General Formula (4) below, characterized in that such method uses a 2-cyclohexene-1-one expressed by General Formula (1) below or 3-hydroxycyclohexane-1-one expressed by General Formula (2) below, and phenol expressed by General Formula (3) below as materials and implements Step (A), Step (B), and Step (C) below, in this order, or Step (D) and Step (C) below, in this order: (In the formulas, each R 2 independently represents an alkyl group, alkoxy group, aromatic hydrocarbon group, or halogen atom, while m independently indicates 0 or an integer of 1 to 4, where R 2 substitution does not occur in the third position when m is 1 or greater, and when m is 2 or greater, R 2 's may be identical or different, and R 2 substitution does not occur in two positions of the same carbon atom. In addition, R 2 and m in General Formula (1) may be identical to or different from R 2 and m in General Formula (2), respectively.) (In the formula, each R 1 independently represents an alkyl group, alkoxy group, aromatic hydrocarbon group, halogen atom, or hydroxyl group, while n indicates 0 or an integer of 1 to 4, where R 1 's may be identical or different when n is 2 or greater.) Step (A): Step to obtain a 1,1,3-trisphenol by causing the 2-cyclohexene-1-one or 3-hydroxycyclohexane-1-one and phenol to react with each other in the presence of a catalyst. Step (B): Step to obtain a bis(4-hydroxyphenyl)cyclohexene by causing the 1,1,3-trisphenol to undergo breakdown reaction. Step (C): Step to obtain a 4,4″-dihydroxy-m-terphenyl by dehydrogenating the bis(4-hydroxyphenyl)cyclohexene. Step (D): Step to obtain a bis(4-hydroxyphenyl)cyclohexene by causing the 2-cyclohexene-1-one or 3-hydroxycyclohexane-1-one and phenol to react with each other in the presence of a catalyst. (In the formula, each R 1 and n is independently the same as the corresponding items in General Formula (3), respectively, while R 2 and m are the same as the corresponding items in General Formula (1) or General Formula (2), respectively.)为了提供一种制造4,4″-二羟基-m-联苯的新方法,本发明提供了一种制造4,4″-二羟基-m-联苯的方法,其由下式(4)表示,其特征在于该方法使用下式(1)表示的2-环己烯-1-酮或下式(2)表示的3-羟基环己烷-1-酮以及下式(3)表示的苯酚作为原料,并按照以下顺序实施步骤(A)、(B)和(C),或按照以下顺序实施步骤(D)和(C):(在公式中,每个R2独立表示烷基、烷氧基、芳香烃基或卤素原子,而m独立表示0或1至4的整数,在m为1或更大时不在第三位置发生R2取代,在m为2或更大时,R2可以相同或不同,并且在同一碳原子的两个位置不发生R2取代。此外,通式(1)中的R2和m可以与通式(2)中的R2和m分别相同或不同。)(在公式中,每个R1独立表示烷基、烷氧基、芳香烃基、卤素原子或羟基,而n表示0或1至4的整数,在n为2或更大时,R1可以相同或不同。)步骤(A):在催化剂的存在下,使2-环己烯-1-酮或3-羟基环己烷-1-酮和苯酚相互反应以获得1,1,3-三酚。步骤(B):使1,1,3-三酚发生分解反应以获得双(4-羟基苯基)环己烯。步骤(C):通过脱氢反应获得4,4″-二羟基-m-联苯。步骤(D):在催化剂的存在下,使2-环己烯-1-酮或3-羟基环己烷-1-酮和苯酚相互反应以获得双(4-羟基苯基)环己烯。(在公式中,每个R1和n分别独立于相应的通式(3)中的相应项,而R2和m与相应的通式(1)或通式(2)中的相应项相同。)

-

Electroorganic chemistry. XXI. Selective formation of .alpha.-acetoxy ketones and general synthesis of 2,3-disubstituted 2-cyclopentenones through the anodic oxidation of enol acetates作者:Tatsuya Shono、Masahisa Okawa、Ikuzo NishiguchiDOI:10.1021/ja00854a030日期:1975.10

表征谱图

-

氢谱1HNMR

-

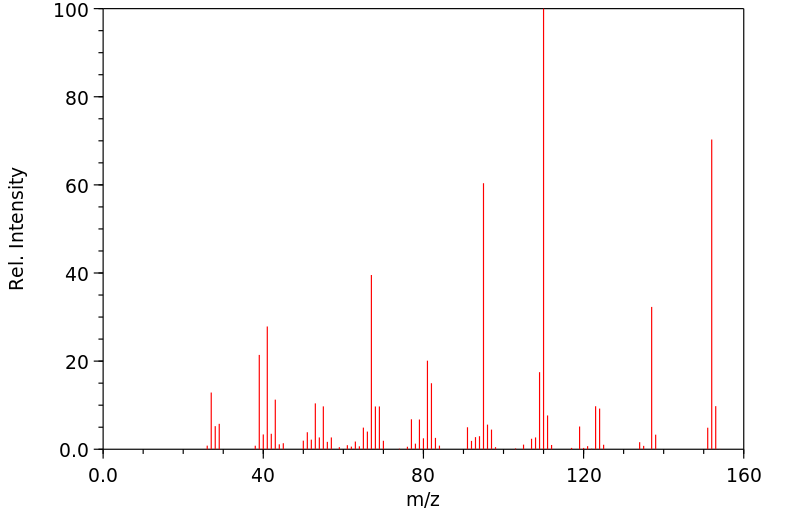

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(5β,6α,8α,10α,13α)-6-羟基-15-氧代黄-9(11),16-二烯-18-油酸

(3S,3aR,8aR)-3,8a-二羟基-5-异丙基-3,8-二甲基-2,3,3a,4,5,8a-六氢-1H-天青-6-酮

(2Z)-2-(羟甲基)丁-2-烯酸乙酯

(2S,4aR,6aR,7R,9S,10aS,10bR)-甲基9-(苯甲酰氧基)-2-(呋喃-3-基)-十二烷基-6a,10b-二甲基-4,10-dioxo-1H-苯并[f]异亚甲基-7-羧酸盐

(1aR,4E,7aS,8R,10aS,10bS)-8-[((二甲基氨基)甲基]-2,3,6,7,7a,8,10a,10b-八氢-1a,5-二甲基-氧杂壬酸[9,10]环癸[1,2-b]呋喃-9(1aH)-酮

(+)顺式,反式-脱落酸-d6

龙舌兰皂苷乙酯

龙脑香醇酮

龙脑烯醛

龙脑7-O-[Β-D-呋喃芹菜糖基-(1→6)]-Β-D-吡喃葡萄糖苷

龙牙楤木皂甙VII

龙吉甙元

齿孔醇

齐墩果醛

齐墩果酸苄酯

齐墩果酸甲酯

齐墩果酸溴乙酯

齐墩果酸二甲胺基乙酯

齐墩果酸乙酯

齐墩果酸3-O-alpha-L-吡喃鼠李糖基(1-3)-beta-D-吡喃木糖基(1-3)-alpha-L-吡喃鼠李糖基(1-2)-alpha-L-阿拉伯糖吡喃糖苷

齐墩果酸 beta-D-葡萄糖酯

齐墩果酸 beta-D-吡喃葡萄糖基酯

齐墩果酸 3-乙酸酯

齐墩果酸 3-O-beta-D-葡吡喃糖基 (1→2)-alpha-L-吡喃阿拉伯糖苷

齐墩果酸

齐墩果-12-烯-3b,6b-二醇

齐墩果-12-烯-3,24-二醇

齐墩果-12-烯-3,21,23-三醇,(3b,4b,21a)-(9CI)

齐墩果-12-烯-3,21,23-三醇,(3b,4b,21a)-(9CI)

齐墩果-12-烯-3,11-二酮

齐墩果-12-烯-2α,3β,28-三醇

齐墩果-12-烯-29-酸,3,22-二羟基-11-羰基-,g-内酯,(3b,20b,22b)-

齐墩果-12-烯-28-酸,3-[(6-脱氧-4-O-b-D-吡喃木糖基-a-L-吡喃鼠李糖基)氧代]-,(3b)-(9CI)

齐墩果-12-烯-28-酸,3,7-二羰基-(9CI)

齐墩果-12-烯-28-酸,3,21,29-三羟基-,g-内酯,(3b,20b,21b)-(9CI)

鼠特灵

鼠尾草酸醌

鼠尾草酸

鼠尾草酚酮

鼠尾草苦内脂

黑蚁素

黑蔓醇酯B

黑蔓醇酯A

黑蔓酮酯D

黑海常春藤皂苷A1

黑檀醇

黑果茜草萜 B

黑五味子酸

黏黴酮

黏帚霉酸