2-(膦酰氧基)丙烯酸酯 | 73-89-2

物质功能分类

中文名称

2-(膦酰氧基)丙烯酸酯

中文别名

3(2H)-异喹啉酮,1,4-二氢-1-硫代

英文名称

phosphoenolpyruvate

英文别名

PEP;2-phosphonooxyprop-2-enoate

CAS

73-89-2

化学式

C3H4O6P

mdl

——

分子量

167.035

InChiKey

DTBNBXWJWCWCIK-UHFFFAOYSA-M

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

计算性质

-

辛醇/水分配系数(LogP):-1.2

-

重原子数:10

-

可旋转键数:3

-

环数:0.0

-

sp3杂化的碳原子比例:0.0

-

拓扑面积:107

-

氢给体数:2

-

氢受体数:6

SDS

反应信息

-

作为反应物:描述:2-(膦酰氧基)丙烯酸酯 在 5-((2,3-dihydrobenzo[b][1,4]dioxin-6-yl)sulfonyl)-1-(methylsulfonyl)indoline 、 pyruvate kinase M2 、 二磷酸腺苷 作用下, 生成 piruvate参考文献:名称:1-(磺酰基)-5-(芳基磺酰基)二氢吲哚作为丙酮酸激酶肿瘤细胞特异性M2亚型的激活剂摘要:癌细胞优先使用糖酵解而不是氧化磷酸化来快速生长。即使氧气充足,它们也会消耗大量的葡萄糖来产生乳酸,这种现象被称为沃伯格效应。这种代谢变化源自糖酵解丙酮酸激酶(PK)的其他剪接同工型的表达从PKM1到PKM2的转变。当PKM1具有组成型活性时,PKM2通过小分子活化剂从无活性的二聚体形式转换为有活性的四聚体形式。相对于许多正常细胞中PKM1的流行率,PKM2在癌细胞中的流行率表明了一种治疗策略,其中PKM2的激活可能抵消癌细胞中异常的细胞代谢,从而降低了细胞的增殖。在这里,我们描述了从2-((2,3-dihydrobenzo [b] [1,4]二恶英-6-基)硫基)-1-(2-甲基-1)衍生的一系列PKM2激活剂的发现和优化。 -(甲基磺酰基)吲哚-5-基)乙酮支架。讨论了合成,SAR分析,酶活性位点对接,酶促反应动力学,选择性和药物性质。DOI:10.1016/j.bmcl.2012.08.054

-

作为产物:描述:参考文献:名称:早期代谢中的单一磷酸化机制——以磷酸烯醇丙酮酸为例摘要:磷酸化被认为是新陈代谢出现的基本反应之一。微生物代谢合成代谢核心中的几乎所有酶促磷酸化反应都会作用于羧酸盐,生成酰基磷酸盐,但有一个明显的例外,即丙酮酸磷酸化为磷酸烯醇丙酮酸 (PEP),其中涉及烯醇化物。我们想知道丙酮酸磷酸化为 PEP 的祖先机制是否也涉及羧酸盐磷酸化而不是现代酶促形式。使用 P 4 O 10作为模型磷酸化剂的丙酮酸磷酸化确实是通过羧酸盐磷酸化发生的,这一点通过使用模型底物、时程实验、液态和固态 NMR 光谱以及 DFT 计算的机理研究得到了证实。原位生成的酰基磷酸随后经历分子内磷酰基转移以产生 PEP。作用于羧酸盐的单一磷酸化机制似乎足以启动包括 PEP 在内的代谢网络,强化了代谢源自自组织化学的情况。DOI:10.1039/d3sc04116f

-

作为试剂:描述:胍基乙酸 在 pyruvate kinase 、 recombinant mitochondrial taurocyamine kinase from Arenicola brasiliensis 、 potassium chloride 、 magnesium acetate 、 2-(膦酰氧基)丙烯酸酯 、 5’-三磷酸腺苷 、 还原型辅酶Ⅰ 、 L-lactate dehydrogenase 作用下, 生成 2-[[氨基-(膦酰氨基)亚甲基]氨基]乙酸参考文献:名称:Identification of amino acid residues responsible for taurocyamine binding in mitochondrial taurocyamine kinase from Arenicola brasiliensis摘要:In order to investigate the residues associated with binding of the substrate taurocyamine in Arenicola mitochondrial taurocyamine kinase (TK), we performed Ala-scanning of the amino acid sequence HTKTV at positions 67-71 on the GS loop, and determined apparent K(m) and V(max) (appK(m) and appV(max), respectively) of the mutant forms for the substrates taurocyamine and glycocyamine. The appK(m) values for taurocyamine of the K69A, T70A and V71A mutants were significantly increased as compared with wild-type, suggesting that these residues are associated with taurocyamine binding. Of special interest is a property of V71A mutant: its catalytic efficiency for glycocyamine was twice that for taurocyamine, indicating that the V71A mutant acts like a glycocyamine kinase, rather than a TK. The role of the amino acid residue K95 of Arenicola MiTK was also examined. K95 was replaced with R, H. V. I. A and E. K95R, K95H and K95I have a 3-fold higher affinity for taurocyamine, and activity was largely lost in K95E. On the other hand, the K95Y mutant showed a rather unique feature: namely, an increase in substrate concentration caused a decrease in initial velocity of the reaction (substrate inhibition). This is the first report on the key amino acid residues responsible for taurocyamine binding in mitochondrial TK. (C) 2011 Elsevier B.V. All rights reserved.DOI:10.1016/j.bbapap.2011.06.003

文献信息

-

Quantitative Analysis in Nanoliter Wells by Prefilling of Wells Using Electrospray Deposition Followed by Sample Introduction with a Coverslip Method作者:Robert Moerman、Johan Knoll、Cristina Apetrei、Lenard R. van den Doel、Gijs W. K. van DedemDOI:10.1021/ac0400515日期:2005.1.1In contrast to performing assays on a substrate using immobilization techniques, wet analysis in nanoliter-sized wells allows quantitative monitoring of enzyme-based reactions by measuring luminescence with time. However, a suitable dispensing method is required to accurately deposit stabilized enzyme solutions into nanoliter wells in such a manner that the enzyme activities are preserved prior to and during measurements. Furthermore, an efficient method is required to add sample liquid to these wells in such a manner that evaporation of assay liquid is completely prevented during sample introduction and monitoring. A powerful methodology is presented in this paper allowing quantitative analysis of enzyme-based reactions in identical nanoliter volumes on-chip. In a first step, picoliter amounts of protein solutions are deposited as uniform dry dots into wells using our reported electrospraying technique (Moerman, R.; Frank, J.; Marijnissen, J. C. M.; Schalkhammer, T. G. M.; van Dedem, G. W. K. Anal. Chem. 2001, 73, 2183−2189.). The silicon chips are then stored at temperatures as low as −80 °C. At the time of analysis, a sample solution is slid into the wells using a coverslip. With the edge of the coverslip, sample solution is pushed across the wells at a speed of 1.5−2.5 cm/s to prevent carryover of reagents to neighboring wells. Evaporation of assay liquid from the wells is prevented because the coverslip seals the wells and “bonds” to the chip by adhesion forces. Electrospraying appears to be an excellent method to deposit enzyme solutions containing up to 20% (w/v) of trehalose without being hampered by clogging of the capillary or splashing of droplets. After being sprayed on-chip (silicon nitride), the enzymes pyruvate kinase and lactate dehydrogenase remained stable for a period of 1.5−2 months at a storage temperature of −20 °C. The coverslip method completely prevented evaporation for minutes up to hours allowing monitoring of enzyme-based reactions in arrays of nanoliter wells.与使用固定化技术在基底上进行检测相比,纳升大小的水湿分析允许通过测量发光随时间的变化来定量监测酶基反应。然而,需要一种合适的分配方法,以准确将稳定的酶溶液沉积到纳升孔中,以保留酶活性,避免在测量期间受到影响。此外,还需要一种高效的方法,以确保在样本引入和监控过程中完全防止试剂液体的蒸发。本文提出了一种强有力的方法,允许在同一芯片上的相同纳升体积内进行酶基反应的定量分析。第一步,使用我们报告的电喷雾技术(Moerman, R.; Frank, J.; Marijnissen, J. C. M.; Schalkhammer, T. G. M.; van Dedem, G. W. K. Anal. Chem. 2001, 73, 2183−2189.)将皮升级的蛋白质溶液均匀地沉积为干点到孔中。然后,将硅芯片储存在低至−80°C的温度下。在分析时,使用盖玻片将样本溶液滑入孔中。通过盖玻片的边缘,以1.5−2.5 cm/s的速度将样本溶液推过孔,以防止试剂残留到邻近的孔中。由于盖玻片密封了孔并通过黏附力“粘合”到芯片,防止了孔中试剂液体的蒸发。电喷雾似乎是一种优秀的方法,可以沉积含有高达20%(w/v)海藻糖的酶溶液,而不会受到毛细管堵塞或液滴飞溅的影响。在芯片上喷雾后(氮化硅基材),酶丙酮酸激酶和乳酸脱氢酶在−20°C的储存温度下保持稳定,持续了1.5−2个月。盖玻片方法完全防止了试剂液体的蒸发,持续数分钟至数小时,允许在纳升孔的阵列中监测酶基反应。

-

Enzymatic synthesis of 3-deoxy- d -manno-octulosonic acid (KDO) and its application for LPS assembly作者:Liuqing Wen、Yuan Zheng、Tiehai Li、Peng George WangDOI:10.1016/j.bmcl.2016.04.061日期:2016.6efficient enzymatic system for the facile synthesis of KDO from easy-to-get starting materials is described. In this one-pot three-enzyme (OPME) system, d-ribulose 5-phosphate, which was prepared from d-xylose, was employed as starting materials. The reaction process involves the isomerization of d-ribulose 5-phosphate to d-arabinose 5-phosphate catalyzed by d-arabinose 5-phosphate isomerase (KdsD), the3-脱氧-d-甘露辛糖酸(KDO)的研究由于其可用性有限而受到阻碍。本文描述了一种有效的酶系统,用于从易于获得的起始材料轻松合成 KDO。在该一锅三酶(OPME)系统中,采用由d-木糖制备的d-核酮糖5-磷酸作为起始原料。反应过程包括在d-阿拉伯糖5-磷酸异构酶(KdsD)催化下,d-核酮糖5-磷酸异构化为d-阿拉伯糖5-磷酸;在d-阿拉伯糖5-磷酸异构酶(KdsD)催化下,d-阿拉伯糖5-磷酸与磷酸烯醇丙酮酸(PEP)进行羟醛缩合。 KDO 8-磷酸合成酶(KdsA),以及KDO 8-磷酸磷酸酶(KdsC)催化的KDO-8-磷酸水解。通过使用该OPME系统,获得了72%的分离产率。获得的KDO通过来自大肠杆菌(WaaA)的KDO转移酶进一步转移至脂质A。

-

Complete Tetrasaccharide Repeat Unit Biosynthesis of the Immunomodulatory <i>Bacteroides fragilis</i> Capsular Polysaccharide A作者:Sunita Sharma、Katelyn M. Erickson、Jerry M. TroutmanDOI:10.1021/acschembio.6b00931日期:2017.1.20gene cluster were heterologously expressed and functionally characterized. Pyruvate modification, catalyzed by WcfO, was found to occur on galactose of the polyisoprenoid-linked disaccharide (AADGal-Gal), and did not occur on galactose linked to uridine diphosphate (UDP) or a set of nitrophenyl-galactose analogues. This pyruvate modification was also found to be required for the incorporation of the next荚膜多糖A(CPSA)是在肠道共生菌脆弱拟杆菌(Bacteroides fragilis)表面上发现的四糖重复单元聚合物在自身免疫性疾病的动物模型中具有治疗潜力。这种治疗潜力归因于其两性离子特性,该特性来自带正电的N-乙酰基-4-氨基半乳糖胺(AADGal)和带负电的4,6-O-丙酮酸半乳糖(PyrGal)。在此报告中,使用荧光聚异戊二烯化学探针,可实现CPSA四糖重复单元的完整酶促组装。拟议的丙酮基转移酶WcfO;吡喃半乳糖突变酶,WcfM;CPSA生物合成基因簇编码的糖基转移酶WcfP和WcfN被异源表达并进行功能表征。发现WcfO催化的丙酮酸修饰发生在聚异戊二烯连接的二糖(AADGal-Gal)的半乳糖上,不会发生在与尿苷二磷酸(UDP)连接的半乳糖或一组硝基苯基-半乳糖类似物中。还发现这种丙酮酸修饰是通过糖基转移酶WcfP将下一个糖掺入N-乙酰半乳糖胺(GalNAc)途径中所必

-

Enzymic synthesis of 3-[3-13C]dehydroquinic acid作者:Martyn Frederickson、Emily J. Parker、John R. Coggins、Chris AbellDOI:10.1039/b309666a日期:——The title compound has been prepared enzymically over four steps from commercially available D-[5-13C]fructose.标题化合物是由市售的 D-[5-13C]果糖通过四个步骤酶解制备而成的。

-

Combinatorial enzymatic assay for the screening of a new class of bacterial cell wall inhibitors作者:Ahmed El Zoeiby、Mélanie Beaumont、Eric Dubuc、François Sanschagrin、Normand Voyer、Roger C LevesqueDOI:10.1016/s0968-0896(02)00447-9日期:2003.4We have developed a screening assay by thin-layer chromatography (TLC) to identify inhibitors for the bacterial essential enzymes MurA, -B, and -C. Libraries of compounds were synthesized using the mix-and-split combinatorial chemistry approach. Screening of the pooled compounds using the developed assay revealed the presence of many pools active in vitro. Pools of interest were tested for antibacterial

表征谱图

-

氢谱1HNMR

-

质谱MS

-

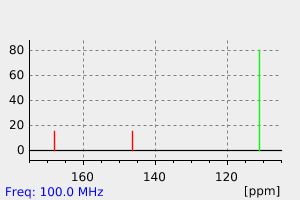

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(11bR,11''bR)-2,2''-[氧双(亚甲基)]双[4-羟基-4,4''-二氧化物-二萘并[2,1-d:1'',2''-f][1,3,2]二氧磷杂七环

(11aR)-10,11,12,13-四氢-5-羟基-3,7-二-1-萘-5-氧化物-二茚基[7,1-de:1'',7''-fg][1,3,2]二氧杂磷杂八环

鲸蜡基磷酸-鲸蜡基磷酸二乙醇胺

高氯酸N,N,N',N',N'',N'',N''',N'''-八甲基二磷四酰胺(1:1:2)锂

非对称二乙基二(二甲基胺基)焦磷酸酯

非4-烯-5-基二苯基磷酸酯

雷公藤甲素O-甲基磷酸酯二苄酯

阿扎替派

间苯二酚双[二(2,6-二甲基苯基)磷酸酯]

锌四戊基二(磷酸酯)

银(1+)二苄基磷酸酯

铵4-(2-甲基-2-丁炔基)苯基4-(2-甲基-2-丙基)苯基磷酸酯

铵2-乙基己基磷酸氢酯

铵2,3-二溴丙基磷酸酯

钾二己基磷酸酯

钾二十烷基磷酸酯

钾二乙基磷酸酯

钾二(8-甲基壬基)磷酸酯

钾[5,7,7-三甲基-2-(1,3,3-三甲基丁基)辛基]磷酸酯

钾2-己基癸基磷酸酯

钴(2+)十三烷基磷酸酯

钡4,4-二乙氧基-2,3-二羟基丁基磷酸酯

钡1,3-二羟基-2-丙基磷酸酯

钠辛基氢磷酸酯

钠癸基氢磷酸酯

钠异丁基氢磷酸酯

钠二苄基磷酸酯

钠二戊基磷酸酯

钠二(十八烷基)磷酸酯

钠二(2-丁氧乙基)磷酸酯

钠O,O-二乙基磷酰蔷薇l烯酸酯

钠4-氨基苯基氢磷酸酯水合物(1:1:1)

钠3,6,9,12,15-五氧杂二十八碳-1-基氢磷酸酯

钠2-乙氧基乙基磷酸酯

钠2,3-二溴丙基磷酸酯

钛酸酯偶联剂NDZ-201

钙敌畏

钙二钠氟-二氧代-氧代膦烷碳酸盐

钙3,9-二氧代-2,4,8,10-四氧杂-3lambda5,9lambda5-二磷杂螺[5.5]十一烷3,9-二氧化物

野尻霉素6-磷酸酯

酸式磷酸戊酯

酚酞单磷酸酯

酚酞单磷酸环己胺盐

酚酞二磷酸四钠盐

酚酞二磷酸四钠

辛基磷酸酯

辛基二氯膦酸酯

辛基二氯丙基磷酸酯

辛基二丙基磷酸酯

赤藓糖醇4-磷酸酯