双十六烷基甲基叔胺 | 16724-61-1

中文名称

双十六烷基甲基叔胺

中文别名

N-十六基-n-甲基-1-十六胺;MA1616

英文名称

N-hexadecyl-N-methylhexadecan-1-amine

英文别名

n-Hexadecyl-N-methyl-1-hexadecanamine

CAS

16724-61-1

化学式

C33H69N

mdl

——

分子量

479.918

InChiKey

KCMTVIZYKDBFFS-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

熔点:36-37 °C

-

沸点:269-271 °C(Press: 1 Torr)

-

密度:0.826±0.06 g/cm3(Predicted)

-

物理描述:Liquid

计算性质

-

辛醇/水分配系数(LogP):15.8

-

重原子数:34

-

可旋转键数:30

-

环数:0.0

-

sp3杂化的碳原子比例:1.0

-

拓扑面积:3.2

-

氢给体数:0

-

氢受体数:1

安全信息

-

海关编码:2921199090

SDS

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 双十六烷基胺 dihexadecylamine 16724-63-3 C32H67N 465.891

反应信息

-

作为反应物:参考文献:名称:Metal Ion Transport Through Bulk Liquid Membrane Mediated by Cationic Ligand Surfactants摘要:一系列N,N,N-三烷基-2-(羟基亚胺基)-2-(吡啶-2-基)乙基-1-胺盐3a-3h和N,N,N-三烷基-4-(羟基亚胺基)-4-(吡啶-2-基)丁基-1-胺盐3i-3l代表具有强大1-(羟基亚胺基)-1-(吡啶-2-基)烷基螯合亚基的阳离子表面活性剂,作为潜在的选择性金属离子萃取剂进行制备。它们的萃取能力在通过大量液膜传输Cu2+、Ni2+、Co2+和Pd2+时进行了测试。将阳离子基团引入萃取剂分子中增加了选择性,并促进了金属离子的传输,通过比较使用配体表面活性剂3和亲脂性烷基吡啶-2-基酮肟2进行的传输可以看出。由配体表面活性剂3介导的金属离子传输的效率和选择性主要取决于它们的结构和亲脂性,即疏水烷基链的数量和长度,以及连接螯合基团与表面活性剂阳离子头基的间隔长度。DOI:10.1135/cccc20050441

-

作为产物:参考文献:名称:Ralston et al., Journal of Organic Chemistry, 1948, vol. 13, p. 189摘要:DOI:

文献信息

-

Polycyclic, fused ring compounds, metal complexes and polymerization process申请人:——公开号:US20020062011A1公开(公告)日:2002-05-23Compounds and metal complexes comprising a polycyclic, fused ring ligand or inertly substituted derivative thereof having up to 60 atoms other than hydrogen, said ligand comprising at least: (1) a cyclopentadienyl ring, (2) a 6,7,or 8 membered ring other than a 6-carbon aromatic ring, and (3) an aromatic ring, with the proviso that said 6, 7, or 8 membered ring (2), is fused to both the cyclopentadienyl ring (1), and the aromatic ring (3), polymerization catalysts, a process to prepare the novel compounds and complexes, and olefin polymerization processes using the same are disclosed.

-

The reactivity of substrate functionalized surfactant vesicles

-

[EN] MULTINUCLEAR TRANSITION METAL POLYMERIZATION CATALYSTS<br/>[FR] CATALYSEURS DE POLYMERISATION DE METAL DE TRANSITION MULTINUCLEAIRE申请人:DOW CHEMICAL CO公开号:WO2004060901A1公开(公告)日:2004-07-22Multinuclear group 4 metal complexes useful as catalyst components for addition polymerizations and polymerization process, especially suited for preparing syndiotactic polymers of vinylaromatic monomers.

-

Polycyclic fused heteroring compounds metal complexes and polymerization process申请人:Graf D David公开号:US20050010039A1公开(公告)日:2005-01-13Metal complexes comprising a polycyclic, heteroatom containing fused ring compound comprising at least a cyclopentadienyl ring having fused thereto a 5-membered polyatomic ring containing one or more ring atoms selected from groups 15 or 16 of the Periodic Table of the Elements and lacking substituents forming 6-membered, aromatic fused rings; polymerization catalysts; and olefin polymerization processes using the same are disclosed.

-

[EN] DIMER SELECTIVE METALLOCENE CATALYSTS, NON-AROMATIC HYDROCARBON SOLUBLE ACTIVATORS, AND PROCESSES TO PRODUCE POLY ALPHA-OLEFIN OLIGMERS THEREWITH<br/>[FR] CATALYSEURS MÉTALLOCÈNES SÉLECTIFS DIMÈRES, ACTIVATEURS SOLUBLES DANS DES HYDROCARBURES NON AROMATIQUES, ET PROCÉDÉS DE PRODUCTION D'OLIGMÈRES POLY ALPHA-OLÉFINIQUES À L'AIDE DE CEUX-CI申请人:EXXONMOBIL CHEMICAL PATENTS INC公开号:WO2021086926A1公开(公告)日:2021-05-06The present disclosure generally relates to process to produce a poly alpha-olefin (PAO), comprising: a) introducing a first alpha-olefin to a first catalyst system comprising non-aromatic hydrocarbon soluble activator and a metallocene compound into a continuous stirred tank reactor or a continuous tubular reactor under first reactor conditions, wherein the first alpha-olefin is preferbaly introduced to the reactor at a flow rate of about 100 g/hr or more, to form a first reactor effluent comprising PAO ( such as at least 60 wt% of PAO dimer and 40 wt% or less of higher oligomers, where the higher oligomers are oligomers that have a degree of polymerization of 3 or more); and b) introducing the first reactor effluent and a second alpha-olefin to a second catalyst composition comprising an acid catalyst, such as BF3, in a second reactor to form a second reactor effluent comprising PAO trimer.

表征谱图

-

氢谱1HNMR

-

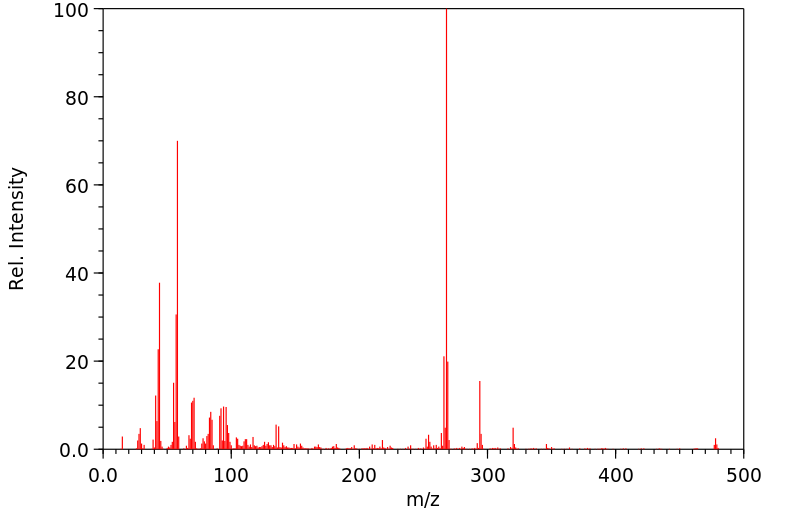

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(乙腈)二氯镍(II)

(R)-(-)-α-甲基组胺二氢溴化物

(N-(2-甲基丙-2-烯-1-基)乙烷-1,2-二胺)

(4-(苄氧基)-2-(哌啶-1-基)吡啶咪丁-5-基)硼酸

(11-巯基十一烷基)-,,-三甲基溴化铵

鼠立死

鹿花菌素

鲸蜡醇硫酸酯DEA盐

鲸蜡硬脂基二甲基氯化铵

鲸蜡基胺氢氟酸盐

鲸蜡基二甲胺盐酸盐

高苯丙氨醇

高箱鲀毒素

高氯酸5-(二甲氨基)-1-({(E)-[4-(二甲氨基)苯基]甲亚基}氨基)-2-甲基吡啶正离子

高氯酸2-氯-1-({(E)-[4-(二甲氨基)苯基]甲亚基}氨基)-6-甲基吡啶正离子

高氯酸2-(丙烯酰基氧基)-N,N,N-三甲基乙铵

马诺地尔

马来酸氢十八烷酯

马来酸噻吗洛尔EP杂质C

马来酸噻吗洛尔

马来酸倍他司汀

顺式环己烷-1,3-二胺盐酸盐

顺式氯化锆二乙腈

顺式吡咯烷-3,4-二醇盐酸盐

顺式双(3-甲氧基丙腈)二氯铂(II)

顺式3,4-二氟吡咯烷盐酸盐

顺式1-甲基环丙烷1,2-二腈

顺式-二氯-反式-二乙酸-氨-环己胺合铂

顺式-二抗坏血酸(外消旋-1,2-二氨基环己烷)铂(II)水合物

顺式-N,2-二甲基环己胺

顺式-4-甲氧基-环己胺盐酸盐

顺式-4-环己烯-1.2-二胺

顺式-4-氨基-2,2,2-三氟乙酸环己酯

顺式-3-氨基环丁烷甲腈盐酸盐

顺式-2-羟基甲基-1-甲基-1-环己胺

顺式-2-甲基环己胺

顺式-2-(苯基氨基)环己醇

顺式-2-(苯基氨基)环己醇

顺式-2-(氨基甲基)-1-苯基环丙烷羧酸盐酸盐

顺式-1,3-二氨基环戊烷

顺式-1,2-环戊烷二胺二盐酸盐

顺式-1,2-环戊烷二胺

顺式-1,2-环丁腈

顺式-1,2-双氨甲基环己烷

顺式--N,N'-二甲基-1,2-环己二胺

顺式-(R,S)-1,2-二氨基环己烷铂硫酸盐

顺式-(2-氨基-环戊基)-甲醇

顺-2-戊烯腈

顺-1,3-环己烷二胺

顺-1,3-双(氨甲基)环己烷