2-噁丁烷酮,3-甲基- | 1823-54-7

中文名称

2-噁丁烷酮,3-甲基-

中文别名

3-甲基氧杂-2-酮

英文名称

α-methyl-β-propiolactone

英文别名

β-Isobutyrolactone;β-butyrolactone;3-Methyloxetan-2-one;3-methyl-oxetan-2-one;3-Methyl-oxetan-2-on;2-Methyl-3-propanolid

CAS

1823-54-7

化学式

C4H6O2

mdl

——

分子量

86.0904

InChiKey

NYBXFCLDEATPCM-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:52 °C(Press: 10 Torr)

-

密度:1.096±0.06 g/cm3(Predicted)

计算性质

-

辛醇/水分配系数(LogP):0.4

-

重原子数:6

-

可旋转键数:0

-

环数:1.0

-

sp3杂化的碳原子比例:0.75

-

拓扑面积:26.3

-

氢给体数:0

-

氢受体数:2

安全信息

-

海关编码:2932209090

SDS

SECTION 1: Identification of the substance/mixture and of the company/undertaking

Product identifiers

Product name : 3-Methyloxetan-2-One

REACH No. : A registration number is not available for this substance as the substance

or its uses are exempted from registration, the annual tonnage does not

require a registration or the registration is envisaged for a later

registration deadline.

Relevant identified uses of the substance or mixture and uses advised against

Identified uses : Laboratory chemicals, Manufacture of substances

SECTION 2: Hazards identification

Classification of the substance or mixture

Classification according to Regulation (EC) No 1272/2008

Eye irritation (Category 2), H319

For the full text of the H-Statements mentioned in this Section, see Section 16.

Classification according to EU Directives 67/548/EEC or 1999/45/EC

Xi Irritant R36

For the full text of the R-phrases mentioned in this Section, see Section 16.

Label elements

Labelling according Regulation (EC) No 1272/2008

Pictogram

Signal word Warning

Hazard statement(s)

H319 Causes serious eye irritation.

Precautionary statement(s)

P305 + P351 + P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove

contact lenses, if present and easy to do. Continue rinsing.

Supplemental Hazard none

Statements

Other hazards

This substance/mixture contains no components considered to be either persistent, bioaccumulative and

toxic (PBT), or very persistent and very bioaccumulative (vPvB) at levels of 0.1% or higher.

SECTION 3: Composition/information on ingredients

Substances

Molecular weight : 86,09 g/mol

Hazardous ingredients according to Regulation (EC) No 1272/2008

Component Classification Concentration

3-Methyloxetan-2-One

Eye Irrit. 2; H319 <= 100 %

Hazardous ingredients according to Directive 1999/45/EC

Component Classification Concentration

3-Methyloxetan-2-One

Xi, R36 <= 100 %

For the full text of the H-Statements and R-Phrases mentioned in this Section, see Section 16

SECTION 4: First aid measures

Description of first aid measures

General advice

Consult a physician. Show this safety data sheet to the doctor in attendance.

If inhaled

If breathed in, move person into fresh air. If not breathing, give artificial respiration. Consult a physician.

In case of skin contact

Wash off with soap and plenty of water. Consult a physician.

In case of eye contact

Rinse thoroughly with plenty of water for at least 15 minutes and consult a physician.

If swallowed

Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician.

Most important symptoms and effects, both acute and delayed

The most important known symptoms and effects are described in the labelling (see section 2.2) and/or in

section 11

Indication of any immediate medical attention and special treatment needed

No data available

SECTION 5: Firefighting measures

Extinguishing media

Suitable extinguishing media

Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide.

Special hazards arising from the substance or mixture

Nature of decomposition products not known.

Advice for firefighters

Wear self-contained breathing apparatus for firefighting if necessary.

Further information

No data available

SECTION 6: Accidental release measures

Personal precautions, protective equipment and emergency procedures

Use personal protective equipment. Avoid dust formation. Avoid breathing vapours, mist or gas. Ensure

adequate ventilation. Avoid breathing dust.

For personal protection see section 8.

Environmental precautions

Do not let product enter drains.

Methods and materials for containment and cleaning up

Pick up and arrange disposal without creating dust. Sweep up and shovel. Keep in suitable, closed

containers for disposal.

Reference to other sections

For disposal see section 13.

SECTION 7: Handling and storage

Precautions for safe handling

Avoid contact with skin and eyes. Avoid formation of dust and aerosols.

Provide appropriate exhaust ventilation at places where dust is formed.

For precautions see section 2.2.

Conditions for safe storage, including any incompatibilities

Store in cool place. Keep container tightly closed in a dry and well-ventilated place.

Storage class (TRGS 510): Non Combustible Solids

Specific end use(s)

Apart from the uses mentioned in section 1.2 no other specific uses are stipulated

SECTION 8: Exposure controls/personal protection

Control parameters

Components with workplace control parameters

Exposure controls

Appropriate engineering controls

Handle in accordance with good industrial hygiene and safety practice. Wash hands before breaks and

at the end of workday.

Personal protective equipment

Eye/face protection

Safety glasses with side-shields conforming to EN166 Use equipment for eye protection tested

and approved under appropriate government standards such as NIOSH (US) or EN 166(EU).

Skin protection

Handle with gloves. Gloves must be inspected prior to use. Use proper glove removal technique

(without touching glove's outer surface) to avoid skin contact with this product. Dispose of

contaminated gloves after use in accordance with applicable laws and good laboratory practices.

Wash and dry hands.

The selected protective gloves have to satisfy the specifications of EU Directive 89/686/EEC and

the standard EN 374 derived from it.

Body Protection

impervious clothing, The type of protective equipment must be selected according to the

concentration and amount of the dangerous substance at the specific workplace.

Respiratory protection

For nuisance exposures use type P95 (US) or type P1 (EU EN 143) particle respirator.For higher

level protection use type OV/AG/P99 (US) or type ABEK-P2 (EU EN 143) respirator cartridges.

Use respirators and components tested and approved under appropriate government standards

such as NIOSH (US) or CEN (EU).

Control of environmental exposure

Do not let product enter drains.

SECTION 9: Physical and chemical properties

Information on basic physical and chemical properties

a) Appearance Form: solid

b) Odour No data available

c) Odour Threshold No data available

d) pH No data available

e) Melting point/freezing No data available

point

f) Initial boiling point and No data available

boiling range

g) Flash point No data available

h) Evaporation rate No data available

i) Flammability (solid, gas) No data available

j) Upper/lower No data available

flammability or

explosive limits

k) Vapour pressure No data available

l) Vapour density No data available

m) Relative density No data available

n) Water solubility No data available

o) Partition coefficient: n- No data available

octanol/water

p) Auto-ignition No data available

temperature

q) Decomposition No data available

temperature

r) Viscosity No data available

s) Explosive properties No data available

t) Oxidizing properties No data available

Other safety information

No data available

SECTION 10: Stability and reactivity

Reactivity

No data available

Chemical stability

Stable under recommended storage conditions.

Possibility of hazardous reactions

No data available

Conditions to avoid

No data available

Incompatible materials

Strong oxidizing agents

Hazardous decomposition products

In the event of fire: see section 5

SECTION 11: Toxicological information

Information on toxicological effects

Acute toxicity

No data available

Skin corrosion/irritation

No data available

Serious eye damage/eye irritation

No data available

Respiratory or skin sensitisation

No data available

Germ cell mutagenicity

No data available

Carcinogenicity

IARC: No component of this product present at levels greater than or equal to 0.1% is identified as

probable, possible or confirmed human carcinogen by IARC.

Reproductive toxicity

No data available

Specific target organ toxicity - single exposure

No data available

Specific target organ toxicity - repeated exposure

No data available

Aspiration hazard

No data available

Additional Information

RTECS: Not available

To the best of our knowledge, the chemical, physical, and toxicological properties have not been

thoroughly investigated.

SECTION 12: Ecological information

Toxicity

No data available

Persistence and degradability

No data available

Bioaccumulative potential

No data available

Mobility in soil

No data available

Results of PBT and vPvB assessment

This substance/mixture contains no components considered to be either persistent, bioaccumulative and

toxic (PBT), or very persistent and very bioaccumulative (vPvB) at levels of 0.1% or higher.

Other adverse effects

No data available

SECTION 13: Disposal considerations

Waste treatment methods

Product

Offer surplus and non-recyclable solutions to a licensed disposal company. Dissolve or mix the material

with a combustible solvent and burn in a chemical incinerator equipped with an afterburner and scrubber.

Contaminated packaging

Dispose of as unused product.

SECTION 14: Transport information

UN number

ADR/RID: - IMDG: - IATA: -

UN proper shipping name

ADR/RID: Not dangerous goods

IMDG: Not dangerous goods

IATA: Not dangerous goods

Transport hazard class(es)

ADR/RID: - IMDG: - IATA: -

Packaging group

ADR/RID: - IMDG: - IATA: -

Environmental hazards

ADR/RID: no IMDG Marine pollutant: no IATA: no

Special precautions for user

No data available

SECTION 15: Regulatory information

This safety datasheet complies with the requirements of Regulation (EC) No. 1907/2006.

Safety, health and environmental regulations/legislation specific for the substance or mixture

No data available

Chemical Safety Assessment

For this product a chemical safety assessment was not carried out

SECTION 16: Other information

Full text of H-Statements referred to under sections 2 and 3.

Eye Irrit. Eye irritation

H319 Causes serious eye irritation.

Full text of R-phrases referred to under sections 2 and 3

Xi Irritant

R36 Irritating to eyes.

Further information

Copyright 2014 Co. LLC. License granted to make unlimited paper copies for internal use

only.

The above information is believed to be correct but does not purport to be all inclusive and shall be

used only as a guide. The information in this document is based on the present state of our knowledge

and is applicable to the product with regard to appropriate safety precautions. It does not represent any

guarantee of the properties of the product. Corporation and its Affiliates shall not be held

liable for any damage resulting from handling or from contact with the above product. See

and/or the reverse side of invoice or packing slip for additional terms and conditions of sale.

上下游信息

反应信息

-

作为反应物:描述:2-噁丁烷酮,3-甲基- 在 H-ZSM-5 作用下, 210.0 ℃ 、166.83 kPa 条件下, 生成 甲基丙烯酸参考文献:名称:Acrylonitrile Derivatives from Epoxide and Carbon Monoxide Reagents摘要:本发明涉及反应器系统和生产丙烯腈及丙烯腈衍生物的工艺。在本发明的优选实施例中,该工艺包括以下步骤:将环氧试剂和一氧化碳试剂通过至少一个进料流入口引入至至少一个反应釜中;将环氧试剂和一氧化碳试剂与羰基化催化剂接触以产生β-内酯中间体;在金属阳离子存在下,将β-内酯中间体与引发剂聚合以产生聚内酯产品;在热解条件下加热聚内酯产品以产生有机酸产品;可选择酯化有机酸产品以产生一个或多个酯产品;并将有机酸产品和/或酯产品与氨试剂在氨氧化条件下反应以产生丙烯腈产品。公开号:US20190002400A1

-

作为产物:描述:参考文献:名称:Sakai, Naoko; Ageishi, Satoru; Isobe, Hiroshi, Journal of the Chemical Society. Perkin transactions I, 2000, # 1, p. 71 - 78摘要:DOI:

文献信息

-

A facile method for synthesis of three carbon-homologated carboxylic acid by regioselective ring-opening of β-propiolactones with organocopper reagents作者:Masatoshi Kawashima、Toshio Sato、Tamotsu FujisawaDOI:10.1016/0040-4020(89)80068-7日期:——β-carbon-oxygen fission to give 3-substituted propionic acids. Among these three kinds of organocopper reagents, diorganocuprate, especially halomagnesium cuprate gave the highest yields of the acids, which was remarkably observed in the ring-opening of sterically hindered β-propiolactones such as β-methyl- and α,β -dimethyl-β-propiolactones and also in the reactions using the organocopper reagents with vinyl and

-

PROCESSES FOR PRODUCING BETA-LACTONE AND BETA-LACTONE DERIVATIVES WITH HETEROGENOUS CATALYSTS申请人:Novomer, Inc.公开号:US20190047972A1公开(公告)日:2019-02-14The present invention is directed to processes from producing beta-lactone and beta-lactone derivatives using heterogenous catalysts. In preferred embodiments of the present invention, the processes comprise the steps: passing a feed stream comprising an epoxide reagent and a carbon monoxide reagent to a reaction zone; contacting the epoxide reagent and the carbon monoxide reagent with a heterogenous catalyst to produce a beta-lactone product in the reaction zone; and removing the beta-lactone product from the reaction zone. In preferred embodiments, the heterogenous catalyst comprises a solid support containing a cationic Lewis acid functional group and a metal carbonyl compound comprising at least one of anionic metal carbonyl compound or a neutral metal carbonyl compound. In certain preferred embodiments, the epoxide reagent and carbon monoxide reagent have a biobased content.

-

COPPER-CATALYZED REACTION OF GRIGNARD REAGENTS WITH β-PROPIOLACTONES: A CONVENIENT METHOD FOR THE SYNTHESIS OF β-SUBSTITUTED PROPIONIC ACIDS

-

ONE-STEP SYNTHESIS OF ω-HYDROXYCARBOXYLIC ACIDS BY THE REACTION OF ω-METALOXYLATED GRIGNARD REAGENTS WITH β-PROPIOLACTONES作者:Tamotsu Fujisawa、Toshiki Mori、Tatsuo Kawara、Toshio SatoDOI:10.1246/cl.1982.569日期:1982.4.5ω-Metaloxylated Grignard reagents reacted with β-propiolactones chemo- and regioselectively in the presence of Li2CuCl4 to afford ω-hydroxycarboxylic acids in high yields.

-

THE REACTION OF SMALL RING COMPOUND WITH CARBON MONOXIDE THE CARBONYLATION OF OXIRANE

表征谱图

-

氢谱1HNMR

-

质谱MS

-

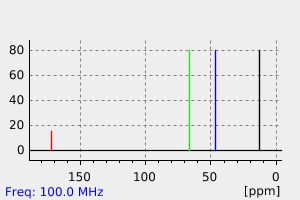

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(+)-(3R)-3-{[叔丁基(二甲基)硅基]氧基}二氢呋喃-2(3H)-酮

龙胆黄碱

龙胆酮胺

高良姜萜内酯

高柠檬酸-gamma-内酯

高普伐他汀内酯二-(叔-丁基二甲基硅烷基)醚

马桑内酯

顺式蒈醛酸内酯

顺式-3,5-二甲基二氢-2H-吡喃-2,6(3H)-二酮

顺式-1,3-环戊烷二甲酸酐

顺式-1,3-环己烷二甲酸酐

阿拉伯酸,2-氨基-2,3,5-三脱氧-3-甲基-,γ-内酯(9CI)

酸,(1S,3R,4R,5R)-3,4-二羟基-7-羰基-6-氧杂二环[3.2.1]辛-1-基2,2,2-三氯乙基酯碳

辛伐他汀4'-甲基醚

辛伐他汀

软木三萜酮3,4-内酯

试剂Menthide

试剂6-Allyl-epsilon-caprolactone

表洛伐他汀

蜂毒

藻酸钠

薇甘菊内酯

葡醛内酯

葡庚糖酸内酯

葡庚糖酸內酯

莫那可林X

莫那可林L

莫那可林J

脱氢抗坏血酸

聚乌拉坦

聚(epsilon-己内酯-delta-戊内酯)

羟基马桑毒内酯

羟基蓍含蓍素

羟基己酸内酯与2,2-二甲基-1,3-丙二醇的聚合物

美伐他汀

绵毛马兜铃内酯

糖质酸-1,4-内酯

穿心莲内酯

科立内脂二醇

硫丹内酯

石蚕苷A

甲酰辛伐他汀

甲瓦龙酸内酯-D4

甲瓦龙酸内酯-D3

甲瓦龙酸内酯-1-13C

甲瓦龙酸内酯-1,2-13C2

甲瓦龙酸内酯

甲基丙烯酸甲瓦龙酸内酯

甲基[(1S,5R,6R)-3-氧代-2-氧杂双环[3.2.1]辛-6-基]乙酸酯

瑞舒伐他汀杂质113