丙酸香茅酯 | 141-14-0

中文名称

丙酸香茅酯

中文别名

3,7-二甲基-6-辛烯醇丙酸酯

英文名称

3,7-dimethyl-6-octen-1-ol propanoate

英文别名

3,7-dimethyloct-6-en-1-yl propionate;β-citronellyl propionate;citronellyl propanoate;citronellyl propionate;propionic acid-(3,7-dimethyl-oct-6-enyl ester);Propionsaeure-(3,7-dimethyl-oct-6-enylester);3,7-dimethyloct-6-enyl propanoate

CAS

141-14-0

化学式

C13H24O2

mdl

MFCD00027010

分子量

212.332

InChiKey

POPNTVRHTZDEBW-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:242 °C(lit.)

-

密度:0.877 g/mL at 25 °C(lit.)

-

闪点:>230 °F

-

溶解度:Almost insoluble in water, soluble in alcohol and oils

-

LogP:4.81

-

物理描述:colourless liquid/fruity-rosy odour

-

折光率:1.443-1.449

-

保留指数:1428;1429;1424.7;1427;1427;1430;1426;1428

-

稳定性/保质期:

该物质在闭合条件下,涂抹于正常或损伤的兔子皮肤上,24小时后观察未发现有刺激作用。若配成4%的凡士林制剂并在人体上进行48小时的封闭性皮肤接触试验,也未产生刺激反应;同样使用此制剂进行最高限度的人体试验,未发现致敏反应。

计算性质

-

辛醇/水分配系数(LogP):4.2

-

重原子数:15

-

可旋转键数:8

-

环数:0.0

-

sp3杂化的碳原子比例:0.769

-

拓扑面积:26.3

-

氢给体数:0

-

氢受体数:2

安全信息

-

WGK Germany:2

-

危险品运输编号:NONH for all modes of transport

-

海关编码:2915509000

-

RTECS号:RH3487500

SDS

制备方法与用途

含量分析

化学性质

按酯测定法(OT-18)中方法一进行。所取试样量为1.2g,计算中的当量因子(e)取95.12。

毒性GRAS(FEMA)。

使用限量FEMA(mg/kg):

软饮料:3.1

冷饮:9.0

糖果:18

焙烤食品:19

胶姆糖:0.8~15

适度为限(FDA §172.515,2000)。

食品添加剂最大允许使用量及最大允许残留量标准| 添加剂中文名称 | 允许使用该种添加剂的食品中文名称 | 添加剂功能 | 最大允许使用量(g/kg) | 最大允许残留量(g/kg) |

|---|---|---|---|---|

| 丙酸香茅酯 | 食品 | 食品用香料 | 用于配制香精的各香料成分不得超过在GB 2760中的最大允许使用量和最大允许残留量 |

无色液体,呈花香、青香、蜡香、玫瑰及水果香气。沸点为242℃。旋光度[α]D+1°30’~-1°30’,混溶于乙醇和大多数非挥发性油,不溶于水。

用途 生产方法上下游信息

反应信息

-

作为反应物:参考文献:名称:Perhydrolase摘要:本发明提供了一种包括至少一种过氧化酶酶的方法和组合物,用于清洁和其他应用。在一些特别优选实施例中,本发明提供了用于生成过氧酸的方法和组合物。本发明在涉及清洁、漂白和消毒的应用中具有特殊用途。公开号:US20080145353A1

-

作为产物:参考文献:名称:量身定制的N杂环卡宾,用于稳定纳米粒子。摘要:N-杂环卡宾(NHC)代表有机金属化学中的一类主要配体,但很少被用作金属纳米粒子(NP)的稳定剂。我们报告了NHC稳定的Pd-NPs的第一个例子,该例子证明了其长期稳定性。这些NHC Pd-NP通过合理的配体交换方案,使用合理设计的长链NHC(LC-NHC)合成。此外,我们证明了Pd-NPs的表面修饰在模型反应中会导致明显的化学选择性。DOI:10.1039/c4cc00654b

文献信息

-

BITTER TASTE MODIFIERS INCLUDING SUBSTITUTED 1-BENZYL-3-(1-(ISOXAZOL-4-YLMETHYL)-1H-PYRAZOL-4-YL)IMIDAZOLIDINE-2,4-DIONES AND COMPOSITIONS THEREOF申请人:SENOMYX, INC.公开号:US20160376263A1公开(公告)日:2016-12-29The present invention includes compounds and compositions known to modify the perception of bitter taste, and combinations of said compositions and compounds with additional compositions, compounds, and products. Exemplary compositions comprise one or more of the following: cooling agents; inactive drug ingredients; active pharmaceutical ingredients; food additives or foodstuffs; flavorants, or flavor enhancers; food or beverage products; bitter compounds; sweeteners; bitterants; sour flavorants; salty flavorants; umami flavorants; plant or animal products; compounds known to be used in pet care products; compounds known to be used in personal care products; compounds known to be used in home products; pharmaceutical preparations; topical preparations; cannabis-derived or cannabis-related products; compounds known to be used in oral care products; beverages; scents, perfumes, or odorants; compounds known to be used in consumer products; silicone compounds; abrasives; surfactants; warming agents; smoking articles; fats, oils, or emulsions; and/or probiotic bacteria or supplements.本发明涵盖已知用于改变苦味感知的化合物和组合物,以及所述组合物和化合物与额外的组合物、化合物和产品的组合。示例组合物包括以下一种或多种:冷却剂;无活性药物成分;活性药用成分;食品添加剂或食品;调味剂或调味增强剂;食品或饮料产品;苦味化合物;甜味剂;苦味剂;酸味调味剂;咸味调味剂;鲜味调味剂;植物或动物产品;已知用于宠物护理产品中的化合物;已知用于个人护理产品中的化合物;已知用于家用产品中的化合物;制药制剂;局部制剂;大麻衍生或与大麻相关的产品;已知用于口腔护理产品中的化合物;饮料;香味、香水或除臭剂;已知用于消费品中的化合物;硅化合物;磨料;表面活性剂;发热剂;吸烟物品;脂肪、油脂或乳化剂;和/或益生菌或补充剂。

-

DERIVATIVES OF 2-ETHYLIDENE NORBORNENE AND THEIR USE IN FRAGRANCE AND FLAVOR APPLICATIONS申请人:TAKASAGO INTERNATIONAL CORPORATION (USA)公开号:US20160355751A1公开(公告)日:2016-12-08Derivatives of 2-ethylidene norbornene are presented. The derivatives can be incorporated into fragrance or flavor compounds and consumer products. A method to impart, enhance or modify the odor properties of a perfuming composition or perfumed consumer product is also provided.

-

A clean enzymatic process for producing flavour esters by direct esterification in switchable ionic liquid/solid phases作者:Pedro Lozano、Juana M. Bernal、Alicia NavarroDOI:10.1039/c2gc36081k日期:——A clean biocatalytic approach for producing flavour esters using switchable ionic liquid/solid phases as reaction/separation media has been developed. The phase behaviour of different IL/flavour acetyl ester (geranyl acetate, citronellyl acetate, neryl acetate and isoamyl acetate) mixtures was studied at several concentrations, resulting for all cases in fully homogeneous liquid media at 50 °C, and solid systems at room temperature. By using an iterative centrifugation protocol on the solid IL/flavour ester mixtures at controlled temperatures, the solid IL phase and the liquid flavour ester phase can be easily separated. The excellent suitability of an immobilized Candida antarctica lipase B (Novozym 435) catalyst in the esterification reaction between an aliphatic carboxylic acid (acetic, propionic, butyric or valeric) and a flavour alcohol (isoamyl alcohol, nerol, citronellol or geraniol) in N,N′,N′′,N′′′-hexadecyltrimethyl-ammonium bis(trifluoromethylsulfonyl)imide ([C16tma][NTf2])IL has been demonstrated, the product yield being improved up to 100% under appropriate reaction conditions (enzyme amount, dehydrating molecular sieves, etc.) at 50 °C. The enzymatic synthesis of sixteen different flavour esters was carried out in [C16tma][NTf2] by means of this approach, providing products of up to 0.757 g mL−1 concentration after IL separation. The residual activity of the enzyme/IL system during seven consecutive operation cycles was shown to be practically unchanged after reuse.开发了一种清洁的生物催化方法,利用可切换的离子液体/固体相作为反应/分离介质来生产香味酯。研究了不同离子液体与香味乙酰酯(香叶醇乙酸酯、香茅醇乙酸酯、奈缬醇乙酸酯和异戊醇乙酸酯)混合物的相行为,在多个浓度下进行研究,结果发现所有情况下在50°C时均为完全均匀的液态介质,而在室温下则为固态系统。通过在控制温度下对固体离子液体/香味酯混合物采用迭代离心分离协议,可以轻松分离出固态离子液体相和液态香味酯相。已证明,在N,N′,N′′,N′′′-十六烷基三甲基铵双(全氟甲基磺酰)亚胺([C16tma][NTf2])离子液体中,固定化的南极酵母脂肪酶B(Novozym 435)催化剂在脂肪族羧酸(醋酸、丙酸、丁酸或戊酸)与香味醇(异戊醇、香叶醇、香茅醇或香茅醇)之间的酯化反应中极为适合,在适当的反应条件(酶量、脱水分子筛等)下,产率提高至100%。通过这种方法在[C16tma][NTf2]中合成了十六种不同的香味酯,离子液体分离后产品浓度达到0.757 g mL−1。在七个连续操作周期中,酶/离子液体系统的残余活性在重复使用后几乎没有变化。

-

Unravelling transition metal-catalyzed terpenic alcohol esterification: a straightforward process for the synthesis of fragrances作者:M. J. da Silva、D. A. M. AyalaDOI:10.1039/c5cy01538c日期:——Iron nitrate is a simple and commercially available Lewis acid and is demonstrated to be able to catalyze β-citronellol esterification with acetic acid, achieving high conversion and ester selectivity (ca. 80 and 70%, respectively), within shorter reaction times than those reported in the literature. To the best of our knowledge, this is the first report of a terpenic alcohol esterification reaction硝酸铁是一种简单且可商购的路易斯酸,并已证明能够用乙酸催化β-香茅醇酯化,在比所报道的反应时间更短的反应时间内实现高转化率和酯选择性(分别约为80%和70%)。在文学中。据我们所知,这是Fe(NO 3)3催化的萜醇酯化反应的首次报道。。该方法是对萜烯醇酯化中常用的缓慢且昂贵的酶促方法的一种有吸引力的替代方法。而且,它避免了中和产物的不希望的步骤,这在无机酸催化的反应中总是需要的。我们已经对不同的金属路易斯酸催化剂的活性进行了研究,发现它们的效率与金属阳离子从乙酸电离产生H +离子的能力直接相关。pH值的测量以及反应中获得的转化率使我们获得了以下趋势:Fe(NO 3)3 > Al(NO 3)3 > Cu(NO 3)2 > Ni(NO 3)2 > Zn(NO 3)2 > Mn(NO 3)2 > Co(NO 3)2 > LiNO 3。前三种被认为是更强的路易斯酸,它们会产生更多的酸性溶液。当我们

-

NOVEL CARBOXYLATE COMPOUND AND METHOD OF PRODUCING THE SAME AND PERFUME COMPOSITION THEREOF申请人:Kitamura Mitsuharu公开号:US20130184486A1公开(公告)日:2013-07-18There are provided a novel carboxylate compound useful as a blending perfume raw material and having a brisk pine-like odor and a method of producing the same and a perfume composition containing such a carboxylate compound. The carboxylate compound of the invention is represented by a general formula (1): wherein R is an alkyl group having two to four carbon atoms.

表征谱图

-

氢谱1HNMR

-

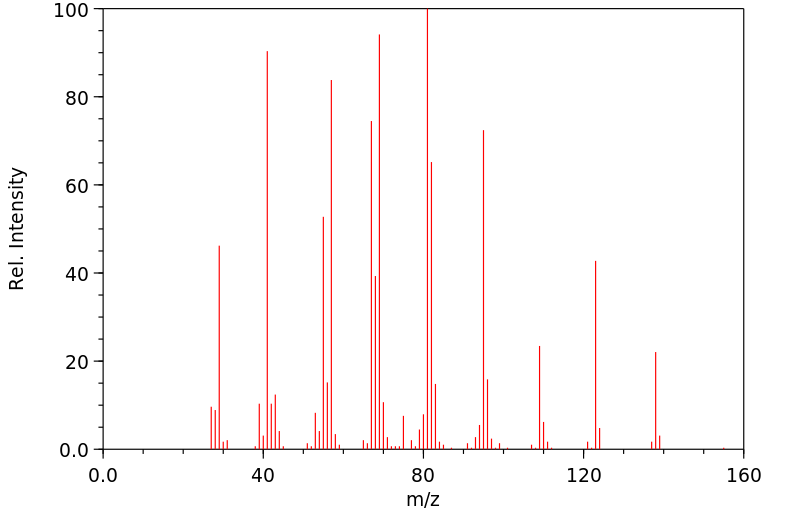

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(±)17,18-二HETE

(±)-辛酰肉碱氯化物

(Z)-5-辛烯甲酯

(Z)-4-辛烯酸

(R)-甲羟戊酸锂盐

(R)-普鲁前列素,游离酸

(R,R)-半乳糖苷

(E)-4-庚烯酸

(E)-4-壬烯酸

(E)-4-十一烯酸

(9Z,12E)-十八烷二烯酸甲酯

(6E)-8-甲基--6-壬烯酸甲基酯-d3

(3R,6S)-rel-8-[2-(3-呋喃基)-1,3-二氧戊环-2-基]-3-羟基-2,6-二甲基-4-辛酮

龙胆二糖

黑曲霉二糖

黄质霉素

麦芽酮糖一水合物

麦芽糖醇

麦芽糖酸

麦芽糖基蔗糖

麦芽糖一水合物

麦芽糖

鳄梨油酸乙酯

鲸蜡醇蓖麻油酸酯

鲸蜡醇油酸酯

鲸蜡硬脂醇硬脂酸酯

鲸蜡烯酸脂

鲸蜡基花生醇

鲫鱼酸

鲁比前列素

鲁比前列素

高级烷基C16-18-醇

高甲羟戊酸

高效氯氰菊酯

高-gamma-亚油酸

马来酸烯丙酯

马来酸氢异丙酯

马来酸氢异丁酯

马来酸氢丙酯

马来酸氢1-[2-(2-羟基乙氧基)乙基]酯

马来酸单乙酯

马来酸单丁酯

马来酸二辛酯

马来酸二癸酯

马来酸二甲酯

马来酸二烯丙酯

马来酸二正丙酯

马来酸二戊基酯

马来酸二异壬酯

马来酸二异丙酯