戊酸丙酯 | 141-06-0

中文名称

戊酸丙酯

中文别名

——

英文名称

propyl valerate

英文别名

Valeriansaeure-propylester;propyl pentanoate

CAS

141-06-0

化学式

C8H16O2

mdl

MFCD00048805

分子量

144.214

InChiKey

ROJKPKOYARNFNB-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

熔点:-70.7°C

-

沸点:167.55°C

-

密度:0.870 g/mL at 20 °C(lit.)

-

闪点:50 °C

-

介电常数:4.0(18℃)

-

LogP:2.823 (est)

-

物理描述:Liquid

-

保留指数:979;988;971;971;977;980;971;981

-

稳定性/保质期:

在常温常压下稳定。禁配物包括强氧化剂、强酸和强碱。遇明火或高温易燃并可能燃烧。

计算性质

-

辛醇/水分配系数(LogP):2.4

-

重原子数:10

-

可旋转键数:6

-

环数:0.0

-

sp3杂化的碳原子比例:0.875

-

拓扑面积:26.3

-

氢给体数:0

-

氢受体数:2

安全信息

-

安全说明:S16

-

危险类别码:R10

-

海关编码:2915600000

-

危险品运输编号:UN 1993 3/PG 3

-

储存条件:请将产品存放在干燥通风的地方保存。

SDS

制备方法与用途

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 γ-戊内酯 5-methyl-dihydro-furan-2-one 108-29-2 C5H8O2 100.117

反应信息

-

作为反应物:参考文献:名称:Vojtko, J., Zeitschrift fur Physikalische Chemie (Leipzig), 1990, vol. 271, # 6, p. 1227 - 1235摘要:DOI:

-

作为产物:描述:4-辛酮 在 sodium phosphinate 、 nicotinamide adenine dinucleotide phosphate 、 monooxygenase from Thermothelomyces thermophila 作用下, 以 1,4-二氧六环 为溶剂, 反应 24.0h, 生成 戊酸丙酯参考文献:名称:来自嗜热真菌嗜热菌的多环酮单加氧酶:一种结构不同的大块底物生物催化剂摘要:区域选择性和立体选择性 Baeyer-Villiger 氧化很难通过经典的化学方法实现,特别是当要转化大的官能化分子时。使用含黄素的 Baeyer-Villiger 单加氧酶 (BVMO) 进行生物催化是解决这些挑战的成熟工具,但已知的 BVMO 在稳定性或底物选择性方面存在缺陷。我们对来自嗜热真菌嗜热嗜热菌的新型 BVMO 进行了表征,确定了其三维结构,并证明了其作为一种有前途的生物催化剂的用途。这种真菌酶表现出优异的对映选择性,作用于各种酮,对多环分子特别活跃。最值得注意的是,我们观察到该酶在转化类固醇时可以对 A 环和 D 环进行氧化。DOI:10.1021/jacs.6b12246

-

作为试剂:描述:2-amino-10,17-dimethyl-2,3,4,5,6,7,8,9,11,12,13,14,15,16-tetradecahydro-1H-cyclopenta[a]phenanthrene-3,4,17-triol 在 potassium nitrate 、 tetrakis(phosphorustrichloride)nickel(0) 、 戊酸丙酯 作用下, 以 二苯醚 为溶剂, 反应 3.84h, 以95%的产率得到参考文献:名称:激素中间体雄甾-17α-甲基-17β-醇-3-酮的合成方法摘要:本发明公开了激素中间体雄甾‑17α‑甲基‑17β‑醇‑3‑酮的合成方法,在反应容器中加入雄甾‑17‑α‑甲基‑2β,3β,17β‑三醇‑4‑氨基,二苯醚溶液,控制溶液温度,控制搅拌速度,加入硝酸钾溶液,继续反应;加入戊酸丙酯溶液,升高溶液温度,分批次加入四(三氯化磷)合镍粉末,继续反应,加入环己烷溶液洗涤,溴化钠溶液洗涤,甲基丙基醚溶液洗涤,在环戊醇溶液中重结晶,脱水剂脱水,得成品雄甾‑17α‑甲基‑17β‑醇‑3‑酮。公开号:CN108239129A

文献信息

-

METHOD FOR CONTINUOUSLY PREPARING CARBOXYLIC ACID ESTER申请人:CHINA PETROCHEMICAL DEVELOPMENT CORPORATION公开号:US20130303796A1公开(公告)日:2013-11-14A method for continuously preparing a carboxylic acid ester is disclosed. In the method of the present invention, a vertical reactor is filled with a solid catalyst, a carboxylic acid and an alcohol are introduced into a lower part of the vertical reactor, esterification is performed to form an esterized mixture, the esterized mixture is output from an upper part of the vertical reactor, and distillation is performed to isolate the carboxylic acid ester. The method of the present invention is simple, easily controlled and environmental friendly, and has significantly high conversion rate and selectivity.

-

Process for Production of Alkyl Tin Alkoxide Compound, and Process for Production of Carbonic Acid Ester Using the Compound申请人:Shinohata Masaaki公开号:US20100292496A1公开(公告)日:2010-11-18The present invention provides a process for producing: a compound represented by XOR 2 ; a dialkyl tin dialkoxide compound having one tin atom, two Sn—R 1 bonds and two Sn—OR 2 bonds; and/or a tetraalkyl dialkoxy distannoxane compound having one Sn—O—Sn bond, in which each tin atom of the tetraalkyl dialkoxy distannoxane compound has two Sn—R 1 bonds and one Sn—OR 2 bond, the process comprising reacting in the absence of a catalyst at least one alkyl tin compound selected from the group consisting of i) and ii) below: i) a dialkyl tin compound having one tin atom, two Sn—R 1 (wherein R 1 represents an alkyl group) bonds, and two Sn—OX bonds (wherein OX is a group in which HOX that is a conjugate acid of OX is a Bronsted acid having a pKa of from 0 to 6.8); and ii) a tetraalkyl distannoxane compound having one Sn—O—Sn bond, in which each tin atom of the tetraalkyl distannoxane compound has two Sn—R 1 bonds and one Sn—OX bond (wherein OX is a group in which HOX that is a conjugate acid of OX is a Bronsted acid having a pKa of from 0 to 6.8); and a carbonic acid ester represented by R 2 OCOOR 2 (wherein R 2 represents a linear or branched, saturated or unsaturated hydrocarbon group, a hydrocarbon group having a saturated or unsaturated cyclic hydrocarbon substituent, or a Y—CH 2 — group (wherein Y represents an alkyl polyalkylene group, an aromatic group or a cyclic saturated or unsaturated alkylene ether group)), and/or an alcohol represented by R 2 OH (wherein R 2 is the same as defined above).本发明提供了一种生产过程:产生一个由XOR表示的化合物;具有一个锡原子、两个Sn—R1键和两个Sn—OR2键的二烷基锡二烷氧化合物;和/或具有一个Sn—O—Sn键的四烷基二烷氧基二锡烷氧化合物,其中四烷基二烷氧基二锡烷氧化合物的每个锡原子具有两个Sn—R1键和一个Sn—OR2键,所述过程包括在缺乏催化剂的情况下反应以下所述组中选择的至少一种烷基锡化合物: i) 具有一个锡原子、两个Sn—R1(其中R1代表烷基基团)键和两个Sn—OX键(其中OX是HOX的共轭酸,HOX是具有从0到6.8的pKa的Bronsted酸的群)的二烷基锡化合物;和 ii) 具有一个Sn—O—Sn键的四烷基二锡烷氧化合物,其中四烷基二锡烷氧化合物的每个锡原子具有两个Sn—R1键和一个Sn—OX键(其中OX是HOX的共轭酸,HOX是具有从0到6.8的pKa的Bronsted酸的群);和 由R2OCOOR2(其中R2代表线性或支链、饱和或不饱和碳氢基团、具有饱和或不饱和环烃取代基的碳氢基团,或Y—CH2—基团(其中Y代表烷基多聚烯基基团、芳香基团或环状饱和或不饱和烷基醚基团))表示的碳酸酯;和/或 由R2OH(其中R2与上述定义相同)表示的醇。

-

A Method for Esterification Reaction Rate Prediction of Aliphatic Monocarboxylic Acids with Primary Alcohols in 1,4-Dioxane Based on Two Parametrical Taft Equation作者:Ján Vojtko、Peter TomčíkDOI:10.1002/kin.20845日期:2014.3concentrations reaction rate depends only on the structure of reactants and, therefore, can be predicted by a correlation equation with two Taft coefficients (inductive and steric effects). From these equations, it is possible to estimate the esterification reaction rate constant for other acid‐alcohol pairs. This methodology may also be suitable for other kinetic systems measured under comparable experimental

-

[EN] PROCESSES FOR PRODUCING CARBOXYLIC ACIDS<br/>[FR] PROCÉDÉS DE PRODUCTION D'ACIDES CARBOXYLIQUES申请人:EASTMAN CHEM CO公开号:WO2020205348A1公开(公告)日:2020-10-08Processes are disclosed for preparing carboxylic acids from organic esters, the processes comprising contacting an ester with water in the presence of an acid catalyst and a homogenizing solvent at conditions effective to form a carboxylic acid. The homogenizing solvent is present in an amount sufficient to form a single-phase reaction mixture comprising the ester, water, and homogenizing solvent. The homogenizing solvent may be selected from acetonitrile, dimethyl sulfoxide, and 1,4-dioxane.

-

Selective Synthesis of 1-<i>O</i>-Alkyl(poly)glycerol Ethers by Catalytic Reductive Alkylation of Carboxylic Acids with a Recyclable Catalytic System作者:Marc Sutter、Wissam Dayoub、Estelle Métay、Yann Raoul、Marc LemaireDOI:10.1002/cssc.201200447日期:2012.12(Poly)glycerol monoethers were synthesized in good yield and selectivity by the catalytic reductive alkylation of glycerol, diglycerol, and triglycerol with readily available, cheap and/or bio‐sourced carboxylic acids. The reaction was catalyzed by 1 mol % of Pd/C under 50 bar H2 using an acid ion‐exchange resin as a recyclable cocatalyst. The catalytic system was recycled several times, and a mechanism

表征谱图

-

氢谱1HNMR

-

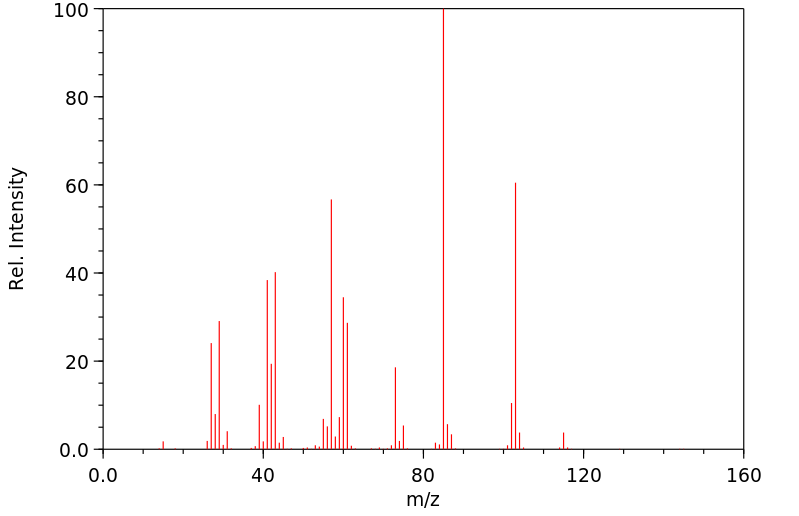

质谱MS

-

碳谱13CNMR

-

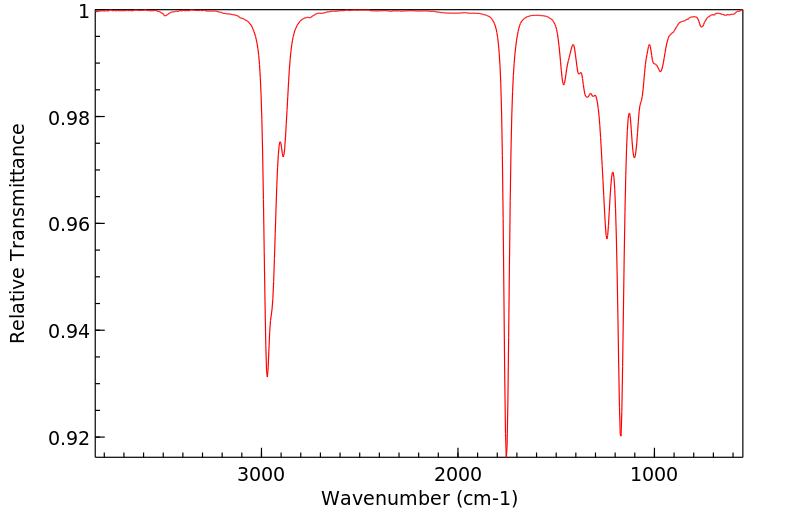

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(±)17,18-二HETE

(±)-辛酰肉碱氯化物

(Z)-5-辛烯甲酯

(Z)-4-辛烯酸

(R)-甲羟戊酸锂盐

(R)-普鲁前列素,游离酸

(R,R)-半乳糖苷

(E)-4-庚烯酸

(E)-4-壬烯酸

(E)-4-十一烯酸

(9Z,12E)-十八烷二烯酸甲酯

(6E)-8-甲基--6-壬烯酸甲基酯-d3

(3R,6S)-rel-8-[2-(3-呋喃基)-1,3-二氧戊环-2-基]-3-羟基-2,6-二甲基-4-辛酮

龙胆二糖

黑曲霉二糖

黄质霉素

麦芽酮糖一水合物

麦芽糖醇

麦芽糖酸

麦芽糖基蔗糖

麦芽糖一水合物

麦芽糖

鳄梨油酸乙酯

鲸蜡醇蓖麻油酸酯

鲸蜡醇油酸酯

鲸蜡硬脂醇硬脂酸酯

鲸蜡烯酸脂

鲸蜡基花生醇

鲫鱼酸

鲁比前列素

鲁比前列素

高级烷基C16-18-醇

高甲羟戊酸

高效氯氰菊酯

高-gamma-亚油酸

马来酸烯丙酯

马来酸氢异丙酯

马来酸氢异丁酯

马来酸氢丙酯

马来酸氢1-[2-(2-羟基乙氧基)乙基]酯

马来酸单乙酯

马来酸单丁酯

马来酸二辛酯

马来酸二癸酯

马来酸二甲酯

马来酸二烯丙酯

马来酸二正丙酯

马来酸二戊基酯

马来酸二异壬酯

马来酸二异丙酯