2-辛炔醛二乙基缩醛 | 16387-55-6

中文名称

2-辛炔醛二乙基缩醛

中文别名

——

英文名称

1,1-diethoxy-2-octyne

英文别名

1,1-diethoxyoct-2-yne

CAS

16387-55-6

化学式

C12H22O2

mdl

MFCD00041654

分子量

198.305

InChiKey

YKXAYRBNHIHDSI-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:120-123 °C18 mm Hg(lit.)

-

密度:0.881 g/mL at 25 °C(lit.)

-

闪点:209 °F

-

稳定性/保质期:

按规定使用和贮存的不会分解,避免与氧化物、酸接触。

计算性质

-

辛醇/水分配系数(LogP):3.5

-

重原子数:14

-

可旋转键数:7

-

环数:0.0

-

sp3杂化的碳原子比例:0.833

-

拓扑面积:18.5

-

氢给体数:0

-

氢受体数:2

安全信息

-

危险品标志:Xi

-

安全说明:S26,S37/39

-

危险类别码:R36/37/38

-

海关编码:2911000000

-

储存条件:请将药品存放在密闭、阴凉、干燥的地方。

SDS

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 丙醛二乙基乙缩醛 Propiolaldehyde diethyl acetal 10160-87-9 C7H12O2 128.171

反应信息

-

作为反应物:描述:2-辛炔醛二乙基缩醛 在 吡啶 、 palladium on activated charcoal 、 Lindlar's catalyst 、 硫酸 、 乙酸乙酯 作用下, 生成 (2E,4E)-2,4-癸二烯酸参考文献:名称:Crombie et al., Journal of the Chemical Society, 1955, p. 1025摘要:DOI:

-

作为产物:描述:参考文献:名称:Neighbouring-group Influence on the Ring Opening of Some 2-Alkyl-1,1,2-tribromocyclopropanes under Phase-transfer Conditions摘要:Several 2-alkyl-1,1,2-tribromocyclopropanes were treated with sodium hydroxide and ethanol under phase-transfer conditions. Ring opening gave mixtures of the corresponding acetylenic diethyl ketals and acetals. When the steric bulk of the alkyl substituent was increased acetal formation dominated, and in the case of 1,1,2-tribromo-2-(tert-butyl)cyclopropane, the acetal was formed as the only product.DOI:10.1007/s00706-005-0358-z

文献信息

-

Rapid and Easy Access to (E)-1,3-Enynes, 1,3-Diynes and Allenes Starting from Propargylic Acetals, Exploiting the Different Reactivity of Lithium and Mixed Lithium–Potassium Organometallic Reagents作者:Marco Blangetti、Annamaria Deagostino、Helèna Rosso、Cristina Prandi、Chiara Zavattaro、Paolo VenturelloDOI:10.1002/ejoc.200700520日期:2007.12The treatment of propargylic acetals with various lithium and mixed lithium–potassium Schlosser reagents, has allowed a one-pot synthesis of (E)-1,3-enynes, 1,3-diynes and allenes, depending on the reaction conditions and the selected base. Various reaction conditions were investigated in order to control the selectivity of the reactions and to obtain pure products. The metallation–elimination sequence

-

Alkenyl copper reagents—18作者:A. Alexakis、A. Commerčon、C. Coulentianos、J.F. NormantDOI:10.1016/s0040-4020(01)91100-7日期:1984.1Lithium diorganocuprates add across the triple bond of substituted and non-substituted acetylenic acetals and ketals to give dialkenylcuprates, which can be decomposed into alkoxyallenes or may be trapped with a variety of electrophiles, such as alkyl, alkenyl, alkynyl and aryl halides. They may also undergo conjugate addition to α-βunsaturated esters and ketones. The method is used for the synthesis

-

Enhanced Diastereoselectivity in Asymmetric Crotylation Reactions Using Propargylic Dicobalt Hexacarbonyl Complexes作者:Meng Sui、James S. PanekDOI:10.1021/ol016016r日期:2001.8.9[reaction: see text] Hexacarbonyl dicobalt complexes of propargylic acetals undergo Lewis acid catalyzed crotylation reactions with enhanced levels of diastereoselectivity (dr 6 to >20:1, syn/anti) while efficiently producing stereochemically well-defined homoallylic ethers. These results are in contrast to uncomplexed propargylic acetals, which undergo the crotylation reactions with low selectivity

-

Chiral Oxazaborolidinone-Mediated Enantioselective Ring-Cleavage Reaction of a Mixture of Diastereomeric 1,3-Dioxolane Acetals: Application to Asymmetric Desymmetrization of <i>meso</i>-1,2-Diols作者:Toshiro Harada、Hideki Yamanaka、Akira OkuDOI:10.1055/s-2001-9730日期:——Ring-cleavage reaction of a mixture of diastereomeric dioxolane acetals syn- and anti-1b-e proceeds in an enantiodifferentiating manner in the presence of chiral Lewis acid 2. The reaction is utilized as a key step in asymmetric desymmetrization of meso-1,2-diols.

-

Preparation of C10-C30-alkenes by partial hydrogenation of alkynes over fixed-bed supported palladium catalysts申请人:——公开号:US20010039368A1公开(公告)日:2001-11-08Alkenes are prepared by partial hydrogenation of alkynes in the liquid phase at from 20 to 250° C. and hydrogen partial pressures of from 0.3 to 200 bar over fixed-bed supported palladium catalysts which are obtainable by heating the support material in the air, cooling, applying a palladium compound and, if required, additionally other metal ions for doping purposes, molding and processing to give monolithic catalyst elements, by a process in which A) alkynes of 10 to 30 carbon atoms are used as starting compounds, B) the palladium compound and, if required, the other metal ions are applied to the support material by impregnation of the heated and cooled support material with a solution containing palladium salts and, if required, other metal ions and subsequent drying, and C) from 10 to 2000 ppm of carbon monoxide (CO) are added to the hydrogenation gas or a corresponding amount of CO is allowed to form in the liquid phase by slight decomposition of a compound which is added to the reaction mixture and eliminates CO under the reaction conditions. The process is particularly advantageous if the partial hydrogenation is carried out in a tube reactor by the trickle-bed or liquid phase procedure with product recycling at cross-sectional loadings of from 20 to 500 m 3 /m 2 *h. The process is particularly suitable for the preparation of 3,7,11,15-tetramethyl-1-hexadecen-3-ol (isophytol), 3,7,11-trimethyl-1-dodecen-3-ol (tetrahydronerolidol), 3,7,11-trimethyl-1,4-dodecadien-3-ol, 3,7,11-trimethyl-1,6-dodecadien-3-ol (dihydronerolidol), 3,7-dimethyloct-1,6-dien-3-ol or 3,7-dimethyloct-1-en-3-ol from the corresponding alkynes.烯烃的制备是通过液相中的炔烃在 20 至 250 摄氏度和 0.3 至 200 巴氢气分压下,在固定床支撑的钯催化剂上进行部分氢化来实现的,钯催化剂可通过在空气中加热支撑材料,冷却,加入钯化合物,必要时加入其他金属离子进行掺杂,成型和加工,得到整体催化剂元件,其工艺过程为 A) 以 10 至 30 个碳原子的炔烃作为起始化合物、 B) 通过用含有钯盐和其他金属离子(如需要)的溶液浸渍加热和冷却后的载体 材料,并随后进行干燥,将钯化合物和其他金属离子(如需要)应用到载体材 料上,以及 C) 在氢化气体中加入 10 至 2000 ppm 的一氧化碳 (CO),或通过加入反应混合物中的化合物的轻微分解在液相中形成相应量的一氧化碳,并在反应条件下消除 CO。 如果部分氢化是在管式反应器中通过涓流床或液相程序进行的,并在横截面载荷为 20 至 500 m 3 /m 2 *h.该工艺尤其适用于制备 3,7,11,15-四甲基-1-十六烯-3-醇(异植物醇)、3,7,11-三甲基-1-十二烯-3-醇(四氢芹醇)、3,7、3,7,11-三甲基-1,4-十二烯-3-醇、3,7,11-三甲基-1,6-十二烯-3-醇(二氢芹醇)、3,7-二甲基辛-1,6-二烯-3-醇或 3,7-二甲基辛-1-烯-3-醇。

表征谱图

-

氢谱1HNMR

-

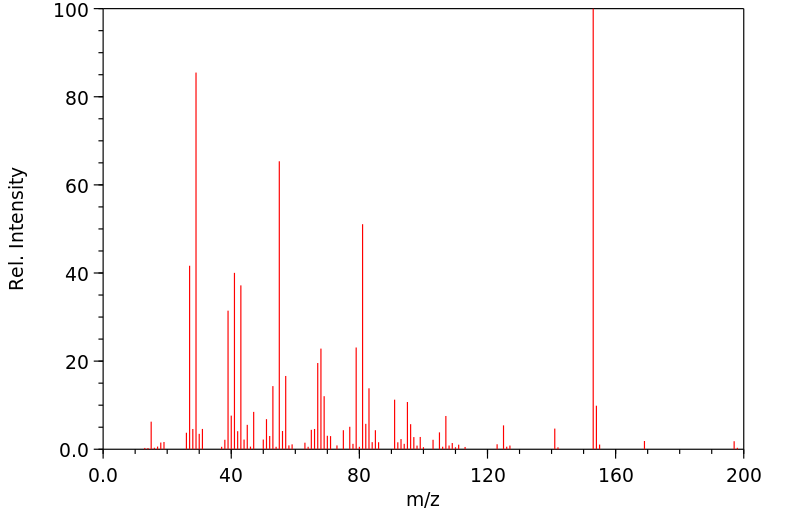

质谱MS

-

碳谱13CNMR

-

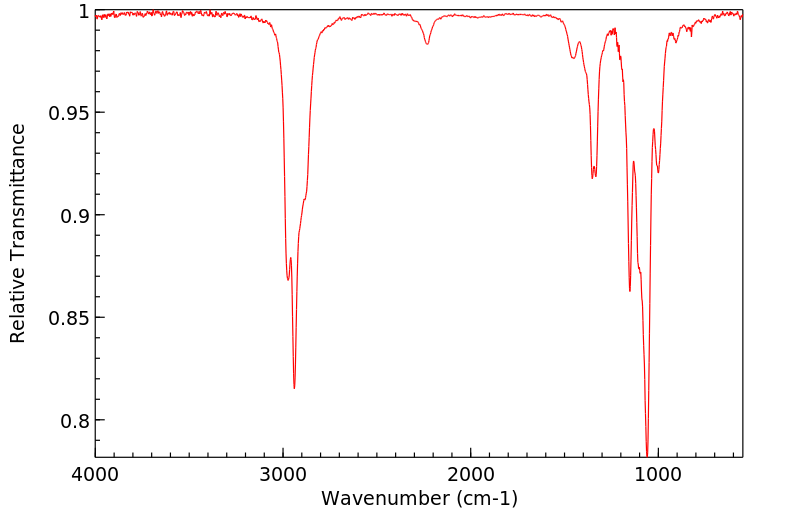

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(反式)-4-壬烯醛

(s)-2,3-二羟基丙酸甲酯

([1-(甲氧基甲基)-1H-1,2,4-三唑-5-基](苯基)甲酮)

(Z)-4-辛烯醛

(S)-氨基甲酸酯β-D-O-葡糖醛酸

(S)-3-(((2,2-二氟-1-羟基-7-(甲基磺酰基)-2,3-二氢-1H-茚满-4-基)氧基)-5-氟苄腈

(R)-氨基甲酸酯β-D-O-葡糖醛酸

(5,5-二甲基-2-(哌啶-2-基)环己烷-1,3-二酮)

(2,5-二氟苯基)-4-哌啶基-甲酮

龙胆苦苷

龙胆二糖甲乙酮氰醇(P)

龙胆二糖丙酮氰醇(P)

龙胆三糖

龙涎酮

齐罗硅酮

齐留通beta-D-葡糖苷酸

鼠李糖

黑芥子苷单钾盐

黑海棉酸钠盐

黑木金合欢素

黑曲霉三糖

黑介子苷

黄尿酸8-O-葡糖苷

麻西那霉素II

麦迪霉素

麦芽糖脎

麦芽糖基海藻糖

麦芽糖1-磷酸酯

麦芽糖

麦芽四糖醇

麦芽四糖

麦芽十糖

麦芽六糖

麦芽五糖水合物

麦芽五糖

麦芽五糖

麦芽五糖

麦芽三糖醇

麦芽三糖

麦芽三糖

麦芽三塘水合

麦芽七糖水合物

麦芽七糖

麦法朵

麦可酚酸-酰基-Β-D-葡糖苷酸

麦利查咪

麝香酮

鹤草酚

鸢尾酚酮 3-C-beta-D-吡喃葡萄糖苷

鸡矢藤苷