O-acryloyl-lactic acid butyl ester | 116660-51-6

中文名称

——

中文别名

——

英文名称

O-acryloyl-lactic acid butyl ester

英文别名

2-Acryloyloxy-propionsaeure-butylester;O-Acryloyl-milchsaeure-butylester;Lactic acid, butyl ester, acrylate;butyl 2-prop-2-enoyloxypropanoate

CAS

116660-51-6

化学式

C10H16O4

mdl

——

分子量

200.235

InChiKey

GMYMGDPDQSRQKW-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:251.7±23.0 °C(Predicted)

-

密度:1.021±0.06 g/cm3(Predicted)

计算性质

-

辛醇/水分配系数(LogP):2.3

-

重原子数:14

-

可旋转键数:8

-

环数:0.0

-

sp3杂化的碳原子比例:0.6

-

拓扑面积:52.6

-

氢给体数:0

-

氢受体数:4

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 乳酸丁酯 n-butyl lactate 138-22-7 C7H14O3 146.186

反应信息

-

作为产物:描述:参考文献:名称:Rehberg; Dixon; Fisher, Journal of the American Chemical Society, 1945, vol. 67, p. 209摘要:DOI:

文献信息

-

PROCESS FOR THE MANUFACTURE OF C1 -C4 ALKYL (METH)ACRYLATES申请人:Riondel Alain公开号:US20070270606A1公开(公告)日:2007-11-22The invention relates to an improved process for the manufacture of C 1 -C 4 alkyl (meth)acrylates by a direct esterification of (meth)acrylic acid by the corresponding alcohol in the presence of sulphuric acid, phenothiazine being used as polymerization inhibitor. The said process comprises a stage of recovering in value the heavy byproducts generated during this manufacture which consists of a distillation at a relatively low temperature and under an inert atmosphere, followed by a catalytic cracking under an inert atmosphere.

-

Processes for producing (meth)acrylic acid compound申请人:MITSUBISHI CHEMICAL CORPORATION公开号:US20040267045A1公开(公告)日:2004-12-30A first and second aspect of the invention relate to a process for producing a (meth)acrylic acid compound and a process for producing a (meth)acrylic ester, respectively. In particular, the second aspect of the invention relates to a process for (meth)acrylic ester production which includes a step in which by-products of a (meth)acrylic ester-yielding reaction are decomposed to recover a (meth)acrylic ester. A third aspect of the invention relates to a method of decomposing by-products of (meth)acrylic ester production in order to recover (meth)acrylic acid, a (meth)acrylic ester, and an alcohol through the decomposition of the by-products of (meth)acrylic ester production. A fourth and fifth aspect of the invention relate to a method of decomposing by-products of (meth)acrylic acid compound production in order to recover (meth)acrylic acid, a (meth)acrylic ester, and an alcohol through the decomposition of by-products of (meth)acrylic acid production and by-products of (meth)acrylic ester production.

-

Method for handling high-viscosity substances申请人:Yada Shuhei公开号:US20050192462A1公开(公告)日:2005-09-01There is provided a method for handling high-viscosity substances discharged from a production process of acrylic acid or esters thereof by gas-phase catalytic oxidation, which method is improved such that upon transporting the high-viscosity substances in a molten state to a storage tank through a pipeline, the retention or clogging of the high-viscosity substances in the pipeline can be effectively prevented without adding a solvent thereto, resulting in smooth transportation thereof through the pipeline. In the method for handling high-viscosity substances discharged from a production process of acrylic acid or esters thereof by gas-phase catalytic oxidation according to the present invention, when the high-viscosity substances are transported to a storage tank through a pipeline, contents of acrylic acid polymers and a polymerization inhibitor in the high-viscosity substances are controlled to not less than 40% by weight and not less than 4% by weight, respectively, and the high-viscosity substances are maintained at a temperature of not less than 110° C.

-

PROCESS FOR PRODUCING (METH)ACRYLIC ACID COMPOUND申请人:MITSUBISHI CHEMICAL CORPORATION公开号:EP1452518A1公开(公告)日:2004-09-01A process for producing (meth)acrylic acid or (meth)acrylic esters, which comprises a reaction step comprising vapor phase catalytic oxidation of propylene, propane or isobutylene and, if necessary, a reaction step comprising an esterification step, characterized in that at the time when a high boiling mixture (hereinafter referred to as a high boiling material) containing a Michael addition product, is decomposed in a decomposition reactor to recover (meth)acrylic acids, while forcibly imparting a liquid flow in the circumferential direction to a liquid reaction residue in the decomposition reactor, the liquid reaction residue is discharged. In a process for recovering a valuable substance by thermally decomposing the high boiling material containing the Michael addition product of (meth)acrylic acids, it is possible to transfer the decomposition residue from the decomposition reactor to the storage tank without clogging, whereby a long-term continuous operation is possible.

-

Process for producing (meth) acrylic acids申请人:MITSUBISHI CHEMICAL CORPORATION公开号:US20040220426A1公开(公告)日:2004-11-04A process for producing (meth)acrylic acid or (meth)acrylic acid esters, which comprises a reaction step comprising vapor phase catalytic oxidation of propylene, propane or isobutylene and, if necessary, a reaction step comprising an esterification step, characterized in that at the time when a high boiling mixture (hereinafter referred to as a high boiling material) containing a Michael addition product, is decomposed in a decomposition reactor to recover (meth)acrylic acids, while forcibly imparting a liquid flow in the circumferential direction to a liquid reaction residue in the decomposition reactor, the liquid reaction residue is discharged. In a process for recovering a valuable substance by thermally decomposing the high boiling material containing the Michael addition product of (meth)acrylic acids, it is possible to transfer the decomposition residue from the decomposition reactor to the storage tank without clogging, whereby a long-term continuous operation is possible.

表征谱图

-

氢谱1HNMR

-

质谱MS

-

碳谱13CNMR

-

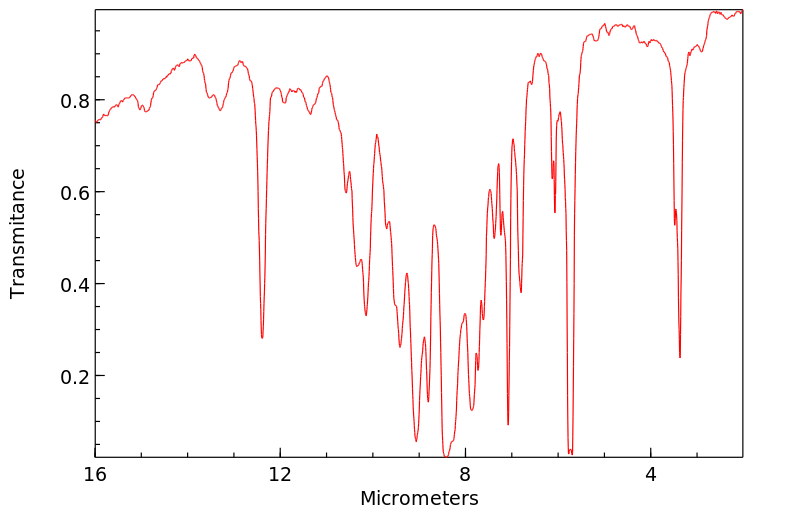

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(甲基3-(二甲基氨基)-2-苯基-2H-azirene-2-羧酸乙酯)

(±)-盐酸氯吡格雷

(±)-丙酰肉碱氯化物

(d(CH2)51,Tyr(Me)2,Arg8)-血管加压素

(S)-(+)-α-氨基-4-羧基-2-甲基苯乙酸

(S)-阿拉考特盐酸盐

(S)-赖诺普利-d5钠

(S)-2-氨基-5-氧代己酸,氢溴酸盐

(S)-2-[[[(1R,2R)-2-[[[3,5-双(叔丁基)-2-羟基苯基]亚甲基]氨基]环己基]硫脲基]-N-苄基-N,3,3-三甲基丁酰胺

(S)-2-[3-[(1R,2R)-2-(二丙基氨基)环己基]硫脲基]-N-异丙基-3,3-二甲基丁酰胺

(S)-1-(4-氨基氧基乙酰胺基苄基)乙二胺四乙酸

(S)-1-[N-[3-苯基-1-[(苯基甲氧基)羰基]丙基]-L-丙氨酰基]-L-脯氨酸

(R)-乙基N-甲酰基-N-(1-苯乙基)甘氨酸

(R)-丙酰肉碱-d3氯化物

(R)-4-N-Cbz-哌嗪-2-甲酸甲酯

(R)-3-氨基-2-苄基丙酸盐酸盐

(R)-1-(3-溴-2-甲基-1-氧丙基)-L-脯氨酸

(N-[(苄氧基)羰基]丙氨酰-N〜5〜-(diaminomethylidene)鸟氨酸)

(6-氯-2-吲哚基甲基)乙酰氨基丙二酸二乙酯

(4R)-N-亚硝基噻唑烷-4-羧酸

(3R)-1-噻-4-氮杂螺[4.4]壬烷-3-羧酸

(3-硝基-1H-1,2,4-三唑-1-基)乙酸乙酯

(2S,4R)-Boc-4-环己基-吡咯烷-2-羧酸

(2S,3S,5S)-2-氨基-3-羟基-1,6-二苯己烷-5-N-氨基甲酰基-L-缬氨酸

(2S,3S)-3-((S)-1-((1-(4-氟苯基)-1H-1,2,3-三唑-4-基)-甲基氨基)-1-氧-3-(噻唑-4-基)丙-2-基氨基甲酰基)-环氧乙烷-2-羧酸

(2S)-2,6-二氨基-N-[4-(5-氟-1,3-苯并噻唑-2-基)-2-甲基苯基]己酰胺二盐酸盐

(2S)-2-氨基-N,3,3-三甲基-N-(苯甲基)丁酰胺

(2S)-2-氨基-3-甲基-N-2-吡啶基丁酰胺

(2S)-2-氨基-3,3-二甲基-N-(苯基甲基)丁酰胺,

(2S)-2-氨基-3,3-二甲基-N-2-吡啶基丁酰胺

(2S,4R)-1-((S)-2-氨基-3,3-二甲基丁酰基)-4-羟基-N-(4-(4-甲基噻唑-5-基)苄基)吡咯烷-2-甲酰胺盐酸盐

(2R,3'S)苯那普利叔丁基酯d5

(2R)-2-氨基-3,3-二甲基-N-(苯甲基)丁酰胺

(2-氯丙烯基)草酰氯

(1S,3S,5S)-2-Boc-2-氮杂双环[3.1.0]己烷-3-羧酸

(1R,5R,6R)-5-(1-乙基丙氧基)-7-氧杂双环[4.1.0]庚-3-烯-3-羧酸乙基酯

(1R,4R,5S,6R)-4-氨基-2-氧杂双环[3.1.0]己烷-4,6-二羧酸

齐特巴坦

齐德巴坦钠盐

齐墩果-12-烯-28-酸,2,3-二羟基-,苯基甲基酯,(2a,3a)-

齐墩果-12-烯-28-酸,2,3-二羟基-,羧基甲基酯,(2a,3b)-(9CI)

黄酮-8-乙酸二甲氨基乙基酯

黄荧菌素

黄体生成激素释放激素(1-6)

黄体生成激素释放激素 (1-5) 酰肼

黄体瑞林

麦醇溶蛋白

麦角硫因

麦芽聚糖六乙酸酯

麦根酸