2-[2-(2-辛酰氧基乙氧基)乙氧基]乙基辛酸酯 | 106-10-5

中文名称

2-[2-(2-辛酰氧基乙氧基)乙氧基]乙基辛酸酯

中文别名

三甘醇双(辛酸酯);2,2'-乙基烯二氧辛二酸二乙酯

英文名称

triethylene glycol dicaprylate

英文别名

triethylene glycol di-n-octanoate;triethylene glycol dioctanoate;1,2-bis-(2-octanoyloxy-ethoxy)-ethane;1,2-Bis-(2-octanoyloxy-aethoxy)-aethan;2,2'-ethylenedioxydiethyl dioctanoate;2-[2-(2-octanoyloxyethoxy)ethoxy]ethyl octanoate

CAS

106-10-5

化学式

C22H42O6

mdl

——

分子量

402.572

InChiKey

YJGHMLJGPSVSLF-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:471.1±25.0 °C(Predicted)

-

密度:0.978±0.06 g/cm3(Predicted)

计算性质

-

辛醇/水分配系数(LogP):5.7

-

重原子数:28

-

可旋转键数:23

-

环数:0.0

-

sp3杂化的碳原子比例:0.91

-

拓扑面积:71.1

-

氢给体数:0

-

氢受体数:6

安全信息

-

海关编码:2918990090

-

储存条件:室温且干燥

SDS

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 辛酸甲酯 methyl octanate 111-11-5 C9H18O2 158.241

反应信息

-

作为产物:描述:辛酸甲酯 、 三乙二醇 在 potassium carbonate 作用下, 155.0 ℃ 、100.0 kPa 条件下, 反应 6.0h, 以90%的产率得到2-[2-(2-辛酰氧基乙氧基)乙氧基]乙基辛酸酯参考文献:名称:一种三甘醇二羧酸酯的制备方法摘要:本发明公开了一种结构式为(Ⅰ)的三甘醇二羧酸酯的制备方法,该方法包括在含无水碳酸钾的催化剂存在下,将结构式为(Ⅱ)的三甘醇与羧酸酯RCOOR1和R’COOR1进行反应,生成包括结构式为(Ⅰ)的三甘醇二羧酸酯和相应的醇HOR1的产物;其中,R和R’相同或不同,各自独立选自直链的C2-C17烷基、支链的C3-C17烷基和C4-C8环烷基中的一种;R1选自C1-C5烷基中的一种。本发明方法利于环境保护;产物收率高,纯度好。公开号:CN104045555B

文献信息

-

DEVELOPING SOLUTION FOR LITHOGRAPHIC PRINTING PLATES AND PRODUCTION METHOD OF LITHOGRAPHIC PRINTING PLATE申请人:ADACHI Keiichi公开号:US20080081295A1公开(公告)日:2008-04-03A developing solution containing at least one of compounds represented by the formulae <1>, <2> and <3> as defined herein, and having a pH of from 2 to 10; and a method for producing a lithographic printing plate, including imagewise exposing a lithographic printing plate precursor including an image recording layer and a support to cure the image recording layer in the exposed area, and developing the exposed lithographic printing plate precursor with an aqueous solution containing at least one of the compounds represented by the formulae <1>, <2> and <3> as defined herein and having a pH of 2 to 10 are provided.本发明提供了一种含有以下式子<1>、<2>和<3>中至少一种化合物的发展溶液,其定义如下,并且具有pH值在2至10之间;以及一种生产平版印刷版的方法,包括图像曝光平版印刷版前体,其中包括图像记录层和支撑层,以治愈所曝光区域的图像记录层,并用含有至少一种以下式子<1>、<2>和<3>中定义的化合物的水溶液,其pH值为2至10,来开发所曝光的平版印刷版前体。

-

INTERLAYER FILM FOR LAMINATED GLASS AND LAMINATED GLASS申请人:Hatta Bungo公开号:US20100279150A1公开(公告)日:2010-11-04It is an object of the present invention to provide an interlayer film for a laminated glass which can reduce transmittance of ultraviolet rays having wavelength of 380 to 400 nm and has excellent durability to light exposure while maintaining high visible light transmittance. The interlayer film for a laminated glass of the present invention is an interlayer film for a laminated glass, which comprises a thermoplastic resin and an indole compound having a structure represented by the following general Chemical Formula (1): wherein R 1 represents an alkyl group having 1 to 3 of carbon atoms, and R 2 represents hydrogen, an alkyl group having 1 to 10 of carbon atoms, or an aralkyl group having 7 to 10 of carbon atoms.

-

THERMOPLASTIC POLYMER COMPOSITION AND MOLDED ARTICLE申请人:Minamide Asako公开号:US20130196164A1公开(公告)日:2013-08-01A thermoplastic polymer composition which is excellent in flexibility, mechanical properties, and moldability and is capable of adhering to ceramics, metals, and synthetic resins even by heat treatment at a low temperature (for example, 190° C. or lower) without the treatment with a primer, and a molded product obtained by using the thermoplastic polymer composition. The thermoplastic polymer composition includes 100 parts by mass of a thermoplastic elastomer (A), 1 to 100 parts by mass of a polyvinyl acetal resin (B), 5 to 100 parts by mass of a polar group-containing olefin-based copolymer (C), and 0.1 to 300 parts by mass of a softener (D). The thermoplastic elastomer (A) is a block copolymer which has a polymer block constituted by aromatic vinyl compound units and a polymer block constituted by conjugated diene units or a hydrogenated product of the block copolymer.

-

FIBER, FABRIC, AND NONWOVEN FABRIC申请人:KURARAY CO., LTD.公开号:US20160002826A1公开(公告)日:2016-01-07To provide: a fiber having excellent adhesiveness, which is able to be bonded to a polar resin, a resin containing an inorganic filler (especially a glass fiber), a ceramic, glass, a metal or the like, without being subjected to a primer treatment or the like; and a nonwoven fabric. A fiber which is formed of a thermoplastic polymer composition that contains (A) a block copolymer which has (a1) at least one polymer block containing a aromatic vinyl compound unit and (a2) at least one polymer block containing a conjugated diene compound unit, (B) a polyvinyl acetal resin and (C) a compatibilizer, said thermoplastic polymer composition containing 5-100 parts by mass of the compatibilizer (C) per 100 parts by mass of the block copolymer (A).

-

GLASS STRUCTURE申请人:SEKISUI CHEMICAL CO., LTD.公开号:US20200292858A1公开(公告)日:2020-09-17A glass structure 10 includes a pair of glass plates 11 and 12 , a light control body 13 disposed between the pair of glass plates 11 and 12 , and an ultraviolet absorbing layer 14 disposed between the light control body 13 and one of the glass plates 11 . The ultraviolet absorbing layer 14 has a maximum transmittance of 10% or less in a wavelength region of 370 nm or more and 400 nm or less and a maximum transmittance of 50% or more in a wavelength region of more than 400 nm and 420 nm or less, and a ratio of a transmittance at 405 nm to a transmittance at 395 nm is 12 or more.

表征谱图

-

氢谱1HNMR

-

质谱MS

-

碳谱13CNMR

-

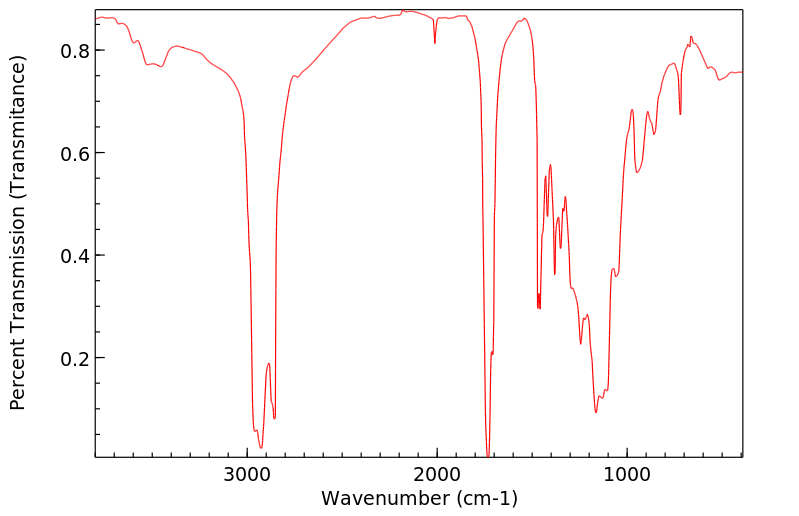

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(±)17,18-二HETE

(±)-辛酰肉碱氯化物

(Z)-5-辛烯甲酯

(Z)-4-辛烯酸

(R)-甲羟戊酸锂盐

(R)-普鲁前列素,游离酸

(R,R)-半乳糖苷

(E)-4-庚烯酸

(E)-4-壬烯酸

(E)-4-十一烯酸

(9Z,12E)-十八烷二烯酸甲酯

(6E)-8-甲基--6-壬烯酸甲基酯-d3

(3R,6S)-rel-8-[2-(3-呋喃基)-1,3-二氧戊环-2-基]-3-羟基-2,6-二甲基-4-辛酮

龙胆二糖

黑曲霉二糖

黄质霉素

麦芽酮糖一水合物

麦芽糖醇

麦芽糖酸

麦芽糖基蔗糖

麦芽糖一水合物

麦芽糖

鳄梨油酸乙酯

鲸蜡醇蓖麻油酸酯

鲸蜡醇油酸酯

鲸蜡硬脂醇硬脂酸酯

鲸蜡烯酸脂

鲸蜡基花生醇

鲫鱼酸

鲁比前列素

鲁比前列素

高级烷基C16-18-醇

高甲羟戊酸

高效氯氰菊酯

高-gamma-亚油酸

马来酸烯丙酯

马来酸氢异丙酯

马来酸氢异丁酯

马来酸氢丙酯

马来酸氢1-[2-(2-羟基乙氧基)乙基]酯

马来酸单乙酯

马来酸单丁酯

马来酸二辛酯

马来酸二癸酯

马来酸二甲酯

马来酸二烯丙酯

马来酸二正丙酯

马来酸二戊基酯

马来酸二异壬酯

马来酸二异丙酯