3-butenyl butyrate | 21698-32-8

中文名称

——

中文别名

——

英文名称

3-butenyl butyrate

英文别名

but-3-enyl butanoate

CAS

21698-32-8

化学式

C8H14O2

mdl

——

分子量

142.198

InChiKey

VDMZXZOJKWISSE-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

保留指数:941;961;971;972

计算性质

-

辛醇/水分配系数(LogP):2

-

重原子数:10

-

可旋转键数:6

-

环数:0.0

-

sp3杂化的碳原子比例:0.62

-

拓扑面积:26.3

-

氢给体数:0

-

氢受体数:2

SDS

反应信息

-

作为反应物:描述:3-butenyl butyrate 在 chromium(III) octaethylporphyrinato tetracarbonylcobaltate 、 间氯过氧苯甲酸 作用下, 以 二氯甲烷 为溶剂, 60.0 ℃ 、6.21 MPa 条件下, 反应 6.0h, 生成 4-(2-butyroxyethyl)-2-propiolactone参考文献:名称:Chromium (III) Octaethylporphyrinato Tetracarbonylcobaltate:一种用于环氧化物羰基化的高活性、选择性和多功能催化剂摘要:详细介绍了高活性和选择性的基于卟啉的环氧化物羰基化催化剂 [(OEP)Cr(THF)2][Co(CO)4](1;OEP = 八乙基卟啉;THF = 四氢呋喃)的开发。配合物 1 是一个分离的离子对,由四羰基钴酸根阴离子和八面体铬卟啉配合物通过两个 THF 配体轴向连接而成。关于环氧化物羰基化为 β-内酯,催化剂 1 表现出优异的周转数(高达 10,000)和周转频率(高达 1670 h(-1)),在氧和空间位阻较小的碳之间发生区域选择性羰基插入环氧底物。配合物 1 对非质子官能团具有高度耐受性,可将一系列脂肪族和脂环族环氧化物以及带有侧链醚、酯和酰胺的环氧化物羰基化。通过对缩水甘油酯羰基化反应条件的仔细控制,实现了β-或γ-内酯异构体的独家生产。通过反应立体化学分析,提出了γ-内酯产物的形成机制。总体而言,已经通过使用 [(OEP)Cr(THF)2][Co(CO)4] 的催化羰基化以快速和DOI:10.1021/ja051874u

-

作为产物:描述:参考文献:名称:Chromium (III) Octaethylporphyrinato Tetracarbonylcobaltate:一种用于环氧化物羰基化的高活性、选择性和多功能催化剂摘要:详细介绍了高活性和选择性的基于卟啉的环氧化物羰基化催化剂 [(OEP)Cr(THF)2][Co(CO)4](1;OEP = 八乙基卟啉;THF = 四氢呋喃)的开发。配合物 1 是一个分离的离子对,由四羰基钴酸根阴离子和八面体铬卟啉配合物通过两个 THF 配体轴向连接而成。关于环氧化物羰基化为 β-内酯,催化剂 1 表现出优异的周转数(高达 10,000)和周转频率(高达 1670 h(-1)),在氧和空间位阻较小的碳之间发生区域选择性羰基插入环氧底物。配合物 1 对非质子官能团具有高度耐受性,可将一系列脂肪族和脂环族环氧化物以及带有侧链醚、酯和酰胺的环氧化物羰基化。通过对缩水甘油酯羰基化反应条件的仔细控制,实现了β-或γ-内酯异构体的独家生产。通过反应立体化学分析,提出了γ-内酯产物的形成机制。总体而言,已经通过使用 [(OEP)Cr(THF)2][Co(CO)4] 的催化羰基化以快速和DOI:10.1021/ja051874u

文献信息

-

[EN] PROCESSES FOR PREPARING COMPLEXES COMPRISING RHODIUM(II) AND CARBOXYLATE LIGANDS<br/>[FR] PROCÉDÉS DE PRÉPARATION DE COMPLEXES COMPRENANT DU RHODIUM(II) ET DES LIGANDS CARBOXYLATE申请人:STOCKHOLM UNIV HOLDING AB公开号:WO2019025575A1公开(公告)日:2019-02-07There is provided herein a process for the preparation of a complex of formula (I): Rh(II)2 Xn, wherein X and n have meanings provided in the description, comprising the step of reacting: (a) a source of Rh(III); and (b) a source of X, wherein the reaction is performed in the presence of: (c) a suitable reducing agent, and wherein the reaction is performed under basic conditions.本文提供了一种制备配方(I)的复合物的过程:Rh(II)2 Xn,其中X和n的含义在描述中提供,包括以下步骤:(a)Rh(III)的来源;和(b)X的来源,其中反应在以下条件下进行:(c)适当的还原剂存在,并且反应在碱性条件下进行。

-

GAS-BARRIER RESIN COMPOSITION AND USE THEREOF申请人:Showa Denko K.K.公开号:EP3660105A1公开(公告)日:2020-06-03The present invention relates to a gas-barrier resin composition, including: a gas-barrier resin (A) having an oxygen permeability coefficient of 1.0×10-14 (cm3·cm/cm2·s·Pa) or less; and a copolymer (B) containing monomer structural units represented by the formula (1), the formula (2), and the formula (3): where: R1 represents a hydrogen atom or a methyl group; R2 represents a hydrocarbon group having 1 to 20 carbon atoms that may be substituted with a halogen atom, a hydroxy group, an alkoxy group, or an amino group; l, m, and n represent numerical values representing molar proportions of the respective monomer structural units, and n may represent 0; and p represents an integer of from 1 to 4, wherein a ratio of a mass of the copolymer (B) to a total mass of the gas-barrier resin (A) and the copolymer (B) is from 1 mass% to 40 mass%. Preferred as the gas-barrier resin (A) are a vinyl alcohol-based resin (A1), a polyamide-based resin (A2), and a polyester-based resin (A3). The present invention can provide a resin composition ameliorated in low flexibility and low impact resistance, which are drawbacks of a gas-barrier resin, without impairing excellent gas barrier properties of the gas-barrier resin.本发明涉及一种气体阻隔树脂组合物,包括:氧气渗透系数为 1.0×10-14 (cm3-cm/cm2-s-Pa) 或以下的气体阻隔树脂 (A);以及含有式 (1)、式 (2) 和式 (3) 所代表的单体结构单元的共聚物 (B): 其中R1 代表氢原子或甲基; R2 代表具有 1 至 20 个碳原子的烃基,可被卤素原子、羟基、烷氧基或氨基取代;l、m 和 n 代表数值,代表各自单体结构单元的摩尔比例,n 可以代表 0;p 代表 1 至 4 的整数,其中共聚物(B)的质量与气体阻隔树脂(A)和共聚物(B)的总质量之比为 1 质量%至 40 质量%。作为气体屏障树脂(A),首选乙烯醇基树脂(A1)、聚酰胺基树脂(A2)和聚酯基树脂(A3)。本发明可提供一种树脂组合物,在不影响气体阻隔性树脂的优异气体阻隔性的前提下,改善气体阻隔性树脂的缺点--低柔韧性和低抗冲击性。

-

Resin film, production method thereof, polarizing plate and liquid crystal display device申请人:Fukagawa Nobutaka公开号:US20070290168A1公开(公告)日:2007-12-20A resin film has a photoelastic coefficient of from 0 to 30×10 −8 cm 2 /N; and Re satisfying the following formulae (1) to (4): 20 nm< Re (548)<300 nm : Formula (1) 0.5< Re (446)/ Re (548)<1 : Formula (2) 1.0< Re (629)/ Re (548)<2.0 : Formula (3) 0.1%≦[ Re (548) at 25° C., 10% RH− Re (548) at 25° C., 80% RH}/ Re (548) at 25° C., 60% RH]≦20%, : Formula (4) wherein Re(λ) represents an in-plane retardation at a wavelength of λ.

-

US7976914B2申请人:——公开号:US7976914B2公开(公告)日:2011-07-12

表征谱图

-

氢谱1HNMR

-

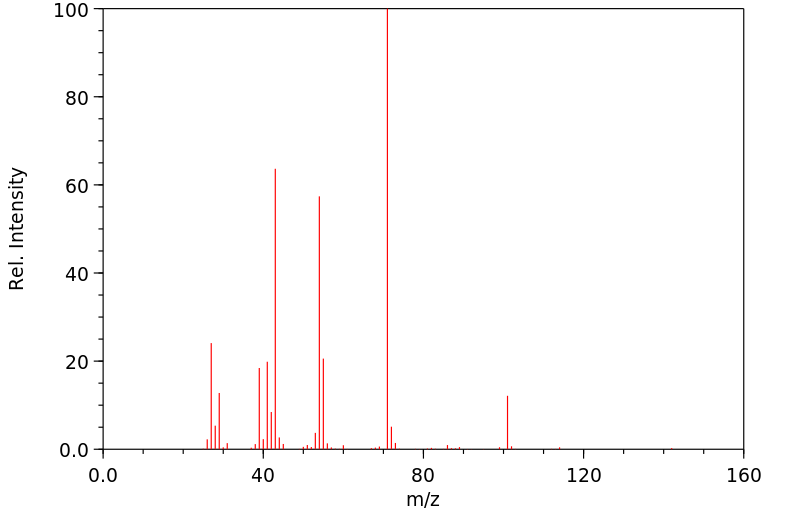

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(±)17,18-二HETE

(±)-辛酰肉碱氯化物

(Z)-5-辛烯甲酯

(Z)-4-辛烯酸

(R)-甲羟戊酸锂盐

(R)-普鲁前列素,游离酸

(R,R)-半乳糖苷

(E)-4-庚烯酸

(E)-4-壬烯酸

(E)-4-十一烯酸

(9Z,12E)-十八烷二烯酸甲酯

(6E)-8-甲基--6-壬烯酸甲基酯-d3

(3R,6S)-rel-8-[2-(3-呋喃基)-1,3-二氧戊环-2-基]-3-羟基-2,6-二甲基-4-辛酮

龙胆二糖

黑曲霉二糖

黄质霉素

麦芽酮糖一水合物

麦芽糖醇

麦芽糖酸

麦芽糖基蔗糖

麦芽糖一水合物

麦芽糖

鳄梨油酸乙酯

鲸蜡醇蓖麻油酸酯

鲸蜡醇油酸酯

鲸蜡硬脂醇硬脂酸酯

鲸蜡烯酸脂

鲸蜡基花生醇

鲫鱼酸

鲁比前列素

鲁比前列素

高级烷基C16-18-醇

高甲羟戊酸

高效氯氰菊酯

高-gamma-亚油酸

马来酸烯丙酯

马来酸氢异丙酯

马来酸氢异丁酯

马来酸氢丙酯

马来酸氢1-[2-(2-羟基乙氧基)乙基]酯

马来酸单乙酯

马来酸单丁酯

马来酸二辛酯

马来酸二癸酯

马来酸二甲酯

马来酸二烯丙酯

马来酸二正丙酯

马来酸二戊基酯

马来酸二异壬酯

马来酸二异丙酯