1,2-环氧-2-甲基丁烷 | 30095-63-7

中文名称

1,2-环氧-2-甲基丁烷

中文别名

1,2-环氧基-2-甲基丁烷

英文名称

2-ethyl-2-methyloxirane

英文别名

rac-1,2-epoxy-2-methylbutane;2-methyl-1,2-epoxybutane;1,2-Epoxy-2-methyl-butan

CAS

30095-63-7

化学式

C5H10O

mdl

MFCD00046998

分子量

86.1338

InChiKey

QZXUQPKFNQQQAJ-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:79 °C (740 mmHg)

-

密度:0.825

-

闪点:-12 °C

-

保留指数:633;634;634;633.3;633.7;634;646

-

稳定性/保质期:

遵照规定使用和储存,则不会发生分解。

计算性质

-

辛醇/水分配系数(LogP):1

-

重原子数:6

-

可旋转键数:1

-

环数:1.0

-

sp3杂化的碳原子比例:1.0

-

拓扑面积:12.5

-

氢给体数:0

-

氢受体数:1

安全信息

-

安全说明:S16,S26,S36/37/39

-

危险类别码:R36/37/38,R11

-

海关编码:2910900090

-

储存条件:存放在阴凉干燥处即可。

SDS

| Name: | 1 2-Epoxy-2-methylbutane Material Safety Data Sheet |

| Synonym: | 2-Ethyl-2-methyloxirane-alpha-Methyl-alpha-ethylethylene oxide |

| CAS: | 30095-63-7 |

Synonym:2-Ethyl-2-methyloxirane-alpha-Methyl-alpha-ethylethylene oxide

Section 2 - COMPOSITION, INFORMATION ON INGREDIENTS

| CAS# | Chemical Name | content | EINECS# |

| 30095-63-7 | 1,2-Epoxy-2-methylbutane | 98 | 250-046-2 |

Risk Phrases: 11 36/37/38

Section 3 - HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW

Highly flammable. Irritating to eyes, respiratory system and skin.Moisture sensitive.Highly flammable.

Potential Health Effects

Eye:

Causes eye irritation. May cause chemical conjunctivitis.

Skin:

Causes skin irritation. May be harmful if absorbed through the skin.

Ingestion:

May cause irritation of the digestive tract. May be harmful if swallowed. Ingestion of large amounts may cause CNS depression.

Inhalation:

Causes respiratory tract irritation. Aspiration may lead to pulmonary edema. May be harmful if inhaled. Vapors may cause dizziness or suffocation. May cause burning sensation in the chest.

Chronic:

No information found.

Section 4 - FIRST AID MEASURES

Eyes: Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical aid.

Skin:

Get medical aid. Flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Wash clothing before reuse.

Ingestion:

Never give anything by mouth to an unconscious person. Get medical aid. Do NOT induce vomiting. If conscious and alert, rinse mouth and drink 2-4 cupfuls of milk or water. Wash mouth out with water.

Inhalation:

Remove from exposure and move to fresh air immediately. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical aid.

Notes to Physician:

Treat symptomatically and supportively.

Section 5 - FIRE FIGHTING MEASURES

General Information:

As in any fire, wear a self-contained breathing apparatus in pressure-demand, MSHA/NIOSH (approved or equivalent), and full protective gear. Vapors may form an explosive mixture with air.

Vapors can travel to a source of ignition and flash back. During a fire, irritating and highly toxic gases may be generated by thermal decomposition or combustion. Use water spray to keep fire-exposed containers cool. Water may be ineffective. Material is lighter than water and a fire may be spread by the use of water. Flammable liquid and vapor. Will be easily ignited by heat, sparks or flame.

Containers may explode if exposed to fire. Runoff from fire control or dilution water may cause pollution.

Extinguishing Media:

Water may spread fire. Use carbon dioxide or dry chemical. DO NOT USE WATER! Do NOT get water inside containers.

Section 6 - ACCIDENTAL RELEASE MEASURES

General Information: Use proper personal protective equipment as indicated in Section 8.

Spills/Leaks:

Absorb spill with inert material (e.g. vermiculite, sand or earth), then place in suitable container. Avoid runoff into storm sewers and ditches which lead to waterways. Clean up spills immediately, observing precautions in the Protective Equipment section. Remove all sources of ignition. Use a spark-proof tool. Provide ventilation. Do not get water inside containers. A vapor suppressing foam may be used to reduce vapors.

Section 7 - HANDLING and STORAGE

Handling:

Ground and bond containers when transferring material. Use spark-proof tools and explosion proof equipment. Avoid breathing dust, vapor, mist, or gas. Avoid contact with eyes, skin, and clothing. Empty containers retain product residue, (liquid and/or vapor), and can be dangerous. Keep container tightly closed. Keep away from heat, sparks and flame. Avoid ingestion and inhalation.

Use with adequate ventilation. Wash clothing before reuse. Do not pressurize, cut, weld, braze, solder, drill, grind, or expose empty containers to heat, sparks or open flames. Keep from contact with moist air and steam.

Storage:

Keep away from sources of ignition. Store in a cool, dry place.

Store in a tightly closed container. Flammables-area. Store protected from moisture.

Section 8 - EXPOSURE CONTROLS, PERSONAL PROTECTION

Engineering Controls:

Facilities storing or utilizing this material should be equipped with an eyewash facility and a safety shower. Use adequate general or local explosion-proof ventilation to keep airborne levels to acceptable levels.

Exposure Limits CAS# 30095-63-7: Personal Protective Equipment Eyes: Wear appropriate protective eyeglasses or chemical safety goggles as described by OSHA's eye and face protection regulations in 29 CFR 1910.133 or European Standard EN166.

Skin:

Wear appropriate protective gloves to prevent skin exposure.

Clothing:

Wear appropriate protective clothing to prevent skin exposure.

Respirators:

Follow the OSHA respirator regulations found in 29 CFR 1910.134 or European Standard EN 149. Use a NIOSH/MSHA or European Standard EN 149 approved respirator if exposure limits are exceeded or if irritation or other symptoms are experienced.

Section 9 - PHYSICAL AND CHEMICAL PROPERTIES

Physical State: Clear liquid

Color: colorless

Odor: Not available.

pH: Not available.

Vapor Pressure: Not available.

Viscosity: Not available.

Boiling Point: 79.5 deg C @ 740mmHg

Freezing/Melting Point: Not available.

Autoignition Temperature: Not available.

Flash Point: -12 deg C ( 10.40 deg F)

Explosion Limits, lower: Not available.

Explosion Limits, upper: Not available.

Decomposition Temperature:

Solubility in water:

Specific Gravity/Density:

Molecular Formula: C5H10O

Molecular Weight: 86.13

Section 10 - STABILITY AND REACTIVITY

Chemical Stability:

Moisture sensitive.

Conditions to Avoid:

Ignition sources, excess heat, exposure to moist air or water.

Incompatibilities with Other Materials:

Oxidizing agents.

Hazardous Decomposition Products:

Carbon monoxide, carbon dioxide.

Hazardous Polymerization: Has not been reported

Section 11 - TOXICOLOGICAL INFORMATION

RTECS#:

CAS# 30095-63-7 unlisted.

LD50/LC50:

Not available.

Carcinogenicity:

1,2-Epoxy-2-methylbutane - Not listed by ACGIH, IARC, or NTP.

Section 12 - ECOLOGICAL INFORMATION

Section 13 - DISPOSAL CONSIDERATIONS

Dispose of in a manner consistent with federal, state, and local regulations.

Section 14 - TRANSPORT INFORMATION

IATA

Shipping Name: FLAMMABLE LIQUID, N.O.S.*

Hazard Class: 3

UN Number: 1993

Packing Group: II

IMO

Shipping Name: FLAMMABLE LIQUID, N.O.S.

Hazard Class: 3

UN Number: 1993

Packing Group: II

RID/ADR

Shipping Name: FLAMMABLE LIQUID, N.O.S.

Hazard Class: 3

UN Number: 1993

Packing group: II

Section 15 - REGULATORY INFORMATION

European/International Regulations

European Labeling in Accordance with EC Directives

Hazard Symbols: XI F

Risk Phrases:

R 11 Highly flammable.

R 36/37/38 Irritating to eyes, respiratory system

and skin.

Safety Phrases:

S 16 Keep away from sources of ignition - No

smoking.

S 26 In case of contact with eyes, rinse immediately

with plenty of water and seek medical advice.

S 36/37/39 Wear suitable protective clothing, gloves

and eye/face protection.

WGK (Water Danger/Protection)

CAS# 30095-63-7: No information available.

Canada

None of the chemicals in this product are listed on the DSL/NDSL list.

CAS# 30095-63-7 is not listed on Canada's Ingredient Disclosure List.

US FEDERAL

TSCA

CAS# 30095-63-7 is not listed on the TSCA inventory.

It is for research and development use only.

SECTION 16 - ADDITIONAL INFORMATION

N/A

上下游信息

-

下游产品

中文名称 英文名称 CAS号 化学式 分子量 (2R)-2-乙基-2-甲基环氧乙烷 (R)-1,2-epoxy-2-methylbutane 33204-47-6 C5H10O 86.1338 —— (S)-1,2-epoxy-2-methylbutane 93132-80-0 C5H10O 86.1338

反应信息

-

作为反应物:描述:参考文献:名称:Fourneau; Tiffeneau, Comptes Rendus Hebdomadaires des Seances de l'Academie des Sciences, 1907, vol. 145, p. 437摘要:DOI:

-

作为产物:描述:2-甲基-丁烯 在 tert-butylperoxyl radical 作用下, 以 gas 为溶剂, 生成 1,2-环氧-2-甲基丁烷参考文献:名称:气相中氧化自由基的反应。第15部分。叔丁基过氧自由基与烯烃的反应摘要:研究了反式-2,2'-偶氮异丁烷与某些脂肪族烯烃混合物的光氧化反应,其反应温度为313至393K。叔丁基过氧自由基与乙烯,2-甲基丙烯,2-甲基丁-1的反应速率常数-烯,2-甲基丁-2-烯和2,3-二甲基丁-2-烯已在393 K下确定。已确定了反应(22)的阿累尼乌斯参数,用于2-甲基丁,但[图解省略] +(CH 3)3 CO 2 ·→[省略图示] +(CH 3)3 CO·(22)2-烯和2,3-二甲基丁-2-烯。它们是8.16±0.38和8.58±0.61的log(A 22 / dm 3 mol –1 S –1)和E22 / kJ mol –1分别为56.6±2.4和48.7±4.1。将在这项工作中获得的数据与从氢过氧基,甲基过氧基和异丙基过氧自由基系列获得的数据进行比较,并与烯烃与过乙酰基之间的加成反应获得的速率数据进行比较。DOI:10.1039/p29840001869

文献信息

-

[EN] SYSTEMS AND METHODS FOR REGIOSELECTIVE CARBONYLATION OF 2,2-DISUBSTITUTED EPOXIDES<br/>[FR] SYSTÈMES ET PROCÉDÉS DE CARBONYLATION RÉGIOSÉLECTIVE D'ÉPOXYDES 2,2-DISUBSTITUÉS申请人:UNIV CORNELL公开号:WO2020102816A1公开(公告)日:2020-05-22Provided are methods of carbonylating cyclic substrates to produce carbonyl ated cyclic products. The cyclic substrates may be 2, 2-di substituted epoxides and the cyclic products may be β,β-di substituted lactones. The method may be carried out by forming and pressurizing a reaction mixture of the cyclic substrate, a solvent, carbon monoxide, and a [LA+][CO(CO)4-] catalyst, where [LA+] is a Lewis acid capable of coordinating to the cyclic substrate. The method may proceed with a regioselectivity of 90:10 or greater. The resulting carbonylated cyclic products may be converted to ketone aldol products that retain the stereochemistry and enantiomeric ratio of the carbonyl ated cyclic products.

-

Reactivity and kinetic–mechanistic studies of regioselective reactions of rhodium porphyrins with unactivated olefins in water that form β-hydroxyalkyl complexes and conversion to ketones and epoxides作者:Jiadi Zhang、Bradford B. Wayland、Lin Yun、Shan Li、Xuefeng FuDOI:10.1039/b912219b日期:——β-hydroxyalkyl rhodium porphyrin complexes which are formed by reactions of terminal alkenes with tetra(p-sulfonatophenyl)porphyrin rhodium(III) complex. The β-hydroxyalkyl rhodium porphyrin complexes in water undergo β-C–H elimination to produce ketones in aqueous pH 9.0 solutions and O–H deprotonation in KOH/DMSO solutions resulting in the rapid and quantitative intramolecular nucleophilic displacement to form

-

Reactions of oxygenated radicals in the gas phase. Part 7. Reactions of methylperoxyl radicals and alkenes作者:David A. Osborne、David J. WaddingtonDOI:10.1039/p29800000925日期:——The reactions of methylperoxyl radicals with alkenes have been studied between 373 and 403 K. The peroxyl radicals were generated by the oxidation of di-t-butyl peroxide. Arrhenius parameters for reaction (18) have been CH3O2·+CC→ [graphic omitted] + CH3O·(18) determined for 2-methylbut-1-ene, 2-methylbut-2-ene, and 2,3-dimethylbut-2-ene. They are log(A18/dm3 mol–1 s–1)= 8.60 ± 0.72,8.16 ± 0.49, and

-

Regioselective Carbonylation of 2,2-Disubstituted Epoxides: An Alternative Route to Ketone-Based Aldol Products作者:Aran K. Hubbell、Anne M. LaPointe、Jessica R. Lamb、Geoffrey W. CoatesDOI:10.1021/jacs.8b12286日期:2019.2.13report the regioselective carbonylation of 2,2-disubstituted epoxides to β,β-disubstituted β-lactones. Mechanistic studies revealed epoxide ring-opening as the turnover limiting step, an insight that facilitated the development of improved reaction conditions using weakly donating, ethereal solvents. A wide range of epoxides can be carbonylated to β-lactones, which are subsequently ring-opened to produce

-

Biocatalytic and Structural Properties of a Highly Engineered Halohydrin Dehalogenase作者:Marcus Schallmey、Robert J. Floor、Bernhard Hauer、Michael Breuer、Peter A. Jekel、Hein J. Wijma、Bauke W. Dijkstra、Dick B. JanssenDOI:10.1002/cbic.201300005日期:2013.5.10Synergistic mutations: A halohydrin dehalogenase with 37 mutations and improved catalytic properties for statin side chain synthesis has been biochemically characterized. Crystal structures with different ligands in the active site give insight into the way in which individual mutations contribute to enhanced stability and faster cyanolysis of epoxides and illustrate the importance of synergistic mutations

表征谱图

-

氢谱1HNMR

-

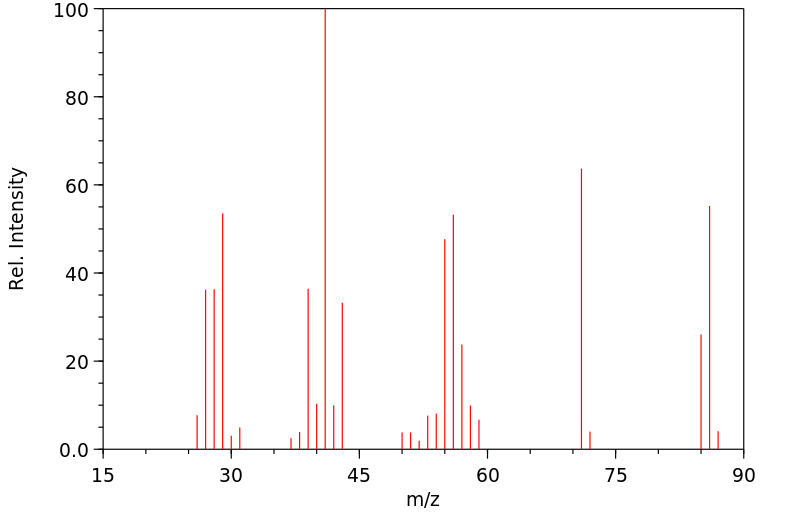

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(S)-4-氯-1,2-环氧丁烷

顺式-环氧琥珀酸氢钾

顺式-1-环己基-2-乙烯基环氧乙烷

顺-(2S,3S)甲基环氧肉桂酸酯

雌舞毒蛾引诱剂

阿洛司他丁

辛基缩水甘油醚

试剂(3S,6S)-(-)-3,6-Diisopropyl-1,4-dioxane-2,5-dione

表氰醇

螺[环氧乙烷-2,2-三环[3.3.1.1~3,7~]癸烷]

蛇根混合碱

benzene oxide

聚碳酸丙烯酯

聚依他丁

羟基乙醛

缩水甘油基异丁基醚

缩水甘油基十六烷基醚

缩水甘油

硬脂基醇聚氧乙烯聚氧丙烯醚

硅烷,三甲基[(3-甲基噁丙环基)乙炔基]-,顺-

盐酸司维拉姆

甲醛与(氯甲基)环氧乙烷,4,4-(1-甲基乙亚基)双酚和2-甲基苯酚的聚合物

甲醛与(氯甲基)环氧乙烷,4,4'-(1-甲基乙亚基)二[苯酚]和4-(1,1,3,3-四甲基丁基)苯酚的聚合物

甲醇环氧乙烷与壬基酚的聚合物

甲胺聚合物与(氯甲基)环氧乙烷

甲硫代环氧丙烷

甲基环氧氯丙烷

甲基环氧巴豆酸酯

甲基环氧乙烷与环氧乙烷和十六烷基或十八烷基醚的聚合物

甲基环氧乙烷与[(2-丙烯基氧基)甲基]环氧乙烷聚合物

甲基环氧丙醇

甲基环氧丙烷

甲基N-丁-3-烯酰甘氨酸酸酯

甲基7-氧杂双环[4.1.0]庚-2,4-二烯-1-羧酸酯

甲基3-环丙基-2-环氧乙烷羧酸酯

甲基1-氧杂螺[2.5]辛烷-2-羧酸酯

甲基(2S,3R)-3-丙基-2-环氧乙烷羧酸酯

甲基(2R,3S)-3-丙基-2-环氧乙烷羧酸酯

甲基(2R,3R)-3-环丙基-2-环氧乙烷羧酸酯

环氧溴丙烷

环氧氯丙烷与双酚A、4-(1,1-二甲乙基)苯酚的聚合物

环氧氯丙烷-d5

环氧氯丙烷-D1

环氧氯丙烷-3,3’-亚氨基二丙胺的聚合物

环氧氯丙烷-2-13C

环氧氯丙烷

环氧氟丙烷

环氧树脂(环氧氯丙烷和二乙二醇)

环氧树脂

环氧柏木烷