己酸异戊酯 | 2198-61-0

中文名称

己酸异戊酯

中文别名

己酸3-甲基丁酯;己酸-3-甲基丁酯;己酸 3-甲基丁酯

英文名称

isopentyl hexanoate

英文别名

isoamyl hexanoate;3-methylbutyl hexanoate;isoamyl caproate

CAS

2198-61-0

化学式

C11H22O2

mdl

MFCD00027280

分子量

186.294

InChiKey

XVSZRAWFCDHCBP-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

熔点:-47°C (estimate)

-

沸点:222 °C(lit.)

-

密度:0.86 g/mL at 25 °C(lit.)

-

闪点:185 °F

-

LogP:4.23

-

物理描述:Colourless liquid with a fruity odour

-

溶解度:Soluble in ethanol and fixed oils, insoluble in glycerol, propylene glycol and water

-

折光率:1.418 - 1.422

-

保留指数:1253;1238;1238;1240;1238;1233;1236;1243;1227;1229;1233;1238;1232;1234;1232;1234;1234;1238

计算性质

-

辛醇/水分配系数(LogP):3.7

-

重原子数:13

-

可旋转键数:8

-

环数:0.0

-

sp3杂化的碳原子比例:0.909

-

拓扑面积:26.3

-

氢给体数:0

-

氢受体数:2

安全信息

-

安全说明:S24/25

-

WGK Germany:2

-

海关编码:29349990

-

RTECS号:MO8389300

-

包装等级:III

-

危险类别:3

-

危险性防范说明:P210,P280,P370+P378,P403+P235,P501

-

危险品运输编号:1993

-

危险性描述:H225

-

储存条件:室温

SDS

Section I.Chemical Product and Company Identification

Chemical Name n-Caproic Acid Isoamyl Ester

Portland OR

Synonym Iso-amyl n-Caproate

CH3(CH2)4COO(CH2)2CH(CH3)2

Chemical Formula

CAS Number 2198-61-0

Section II. Composition and Information on Ingredients

Chemical Name CAS Number Percent (%) TLV/PEL Toxicology Data

n-Caproic Acid Isoamyl Ester 2198-61-0 ---------- Not available. Rabbit LD50 (dermal) >5000mg/kg

Rat LD50 (oral) >5000mg/kg

Section III. Hazards Identification

Acute Health Effects No specific information is available in our data base regarding the toxic effects of this material for humans. However,

exposure to any chemical should be kept to a minimum. Skin and eye contact may result in irritation. May be harmful if

inhaled or ingested. Always follow safe industrial hygiene practices and wear proper protective equipment when handling

this compound.

Chronic Health Effects CARCINOGENIC EFFECTS : Not available.

MUTAGENIC EFFECTS : Not available.

TERATOGENIC EFFECTS : Not available.

DEVELOPMENTAL TOXICITY: Not available.

Repeated exposure to an highly toxic material may produce general deterioration of health by an accumulation in one or

many human organs.

Section IV. First Aid Measures

Eye Contact

Check for and remove any contact lenses. IMMEDIATELY flush eyes with runing water for at least 15 minutes. keeping

eyelids open. COLD water may be used. DO NOT use an eye oitment. Flush eyes with running water for a minimum of

15 minutes, occasionally lifting the upper eyelids. Seek medical attention. Treat symptomatically and supportively.

Skin Contact After contact with skin, wash immediately with plenty of water. Gently and thorough wash the contaminated skin with

running water and non-abrasive soap. Be particularly careful to clean folds, crevices, creases and groin. COLD water

may be used. Cover the irritated skin with an emollient. Seek medical attention. Treat symptomatically and supportively.

Wash any contaminated clothing before reusing.

Inhalation If the victim is not breathing, perform artificial respiration. Loosen tight clothing such as a collar, tie, belt or waistband. If

breathing is difficult, oxygen can be administered. Seek medical attention. Treat symptomatically and supportively.

Ingestion INDUCE VOMITING by sticking finger in throat. Lower the head so that the vomit will not reenter the mouth and throat.

Loosen tight clothing such as a collar, tie, belt, or waistband. If the victim is not breathing, administer artificial respiration.

Examine the lips and mouth to ascertain whether the tissues are damaged, a possible indication that the toxic material

was ingested; the absence of such signs, however, is not conclusive. Seek immediate medical attention and, if possible,

show the chemical label. Treat symptomatically and supportively.

Section V. Fire and Explosion Data

Not available.

Flammability Combustible. Auto-Ignition

Flash Points Flammable Limits

85°C (185°F). Not available.

Combustion Products

These products are toxic carbon oxides (CO, CO 2).

Fire Hazards

No specific information is available regarding the flammability of this compound in the presence of various materials.

Explosion Hazards Risks of explosion of the product in presence of mechanical impact: Not available.

Risks of explosion of the product in presence of static discharge: Not available.

No additional information is available regarding the risks of explosion.

Fire Fighting Media

SMALL FIRE: Use DRY chemicals, CO 2, water spray or foam.

and Instructions LARGE FIRE: Use water spray, fog or foam. DO NOT use water jet.

Continued on Next Page

n-Caproic Acid Isoamyl Ester

Section VI. Accidental Release Measures

Spill Cleanup Combustible material.

Instructions Keep away from heat and sources of ignition. Mechanical exhaust required. Stop leak if without risk. Finish cleaning the

spill by rinsing any contaminated surfaces with copious amounts of water. Consult federal, state, and/or local authorities

for assistance on disposal.

Section VII. Handling and Storage

Handling and Storage COMBUSTIBLE. Handle with caution and minimize exposure. Keep away from heat and sources of ignition. Mechanical

exhaust required. Avoid excessive heat and light. DO NOT ingest. Do not breathe gas, fumes, vapor or spray. Wear

Information

suitable protective clothing. If ingested, seek medical advice immediately and show the container or the label. Treat

symptomatically and supportively.

Always store away from incompatible compounds such as oxidizing agents.

Section VIII. Exposure Controls/Personal Protection

Engineering Controls Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their

respective threshold limit value. Ensure that eyewash station and safety shower is proximal to the work-station location.

Personal Protection Splash goggles. Lab coat. Dust respirator. Boots. Gloves. Suggested protective clothing might not be sufficient; consult

a specialist BEFORE handling this product.

Exposure Limits Not available.

Section IX. Physical and Chemical Properties

Physical state @ 20°C Colorless liquid. Solubility

Not available.

0.86

Specific Gravity

Molecular Weight Partition Coefficient

186.29 Not available.

Boiling Point Vapor Pressure

222°C (431.6°F) Not available.

Melting Point Not available. Vapor Density Not available.

Refractive Index Not available. Volatility Not available.

Critical Temperature Not available. Odor Not available.

Viscosity Not available. Taste Not available.

Section X. Stability and Reactivity Data

Stability

This material is stable if stored under proper conditions. (See Section VII for instructions)

Conditions of Instability

Avoid excessive heat and light.

Incompatibilities

Reactive with strong oxidizing agents.

Section XI. Toxicological Information

RTECS Number MO8389300

Routes of Exposure Eye contact. Ingestion. Inhalation.

Toxicity Data Rabbit LD50 (dermal) >5000mg/kg

Rat LD50 (oral) >5000mg/kg

Chronic Toxic Effects CARCINOGENIC EFFECTS : Not available.

MUTAGENIC EFFECTS : Not available.

TERATOGENIC EFFECTS : Not available.

DEVELOPMENTAL TOXICITY: Not available.

Repeated exposure to an highly toxic material may produce general deterioration of health by an accumulation in one or

many human organs.

Acute Toxic Effects No specific information is available in our data base regarding the toxic effects of this material for humans. However,

exposure to any chemical should be kept to a minimum. Skin and eye contact may result in irritation. May be harmful if

inhaled or ingested. Always follow safe industrial hygiene practices and wear proper protective equipment when handling

this compound.

Continued on Next Page

n-Caproic Acid Isoamyl Ester

Section XII. Ecological Information

Ecotoxicity Not available.

Environmental Fate Not available.

Section XIII. Disposal Considerations

Recycle to process, if possible. Consult your local or regional authorities. You may be able to dissolve or mix material with

Waste Disposal

a combustible solvent and burn in a chemical incinerator equipped with an afterburner and scrubber system. Observe all

federal, state, and local regulations when disposing of the substance.

Section XIV. Transport Information

DOT Classification Not a DOT controlled material (United States).

PIN Number Not applicable.

Proper Shipping Name

Not applicable.

Packing Group (PG) Not applicable.

DOT Pictograms

Section XV. Other Regulatory Information and Pictograms

TSCA Chemical Inventory This compound is ON the EPA Toxic Substances Control Act (TSCA) inventory list.

(EPA)

WHMIS Classification

WHMIS CLASS B-3: Combustible liquid with a flash point between 35°C (100°F) and 93.3°C (200°F).

(Canada)

EINECS Number (EEC) 218-600-8

EEC Risk Statements Not available.

SECTION 16 - ADDITIONAL INFORMATION

N/A

制备方法与用途

含量分析

化学性质

按酯测定法(OT-18)中方法一进行。所取试样量为1.2g,计算中的当量因子(e)取93.15。

毒性GRAS(FEMA)。

使用限量FEMA(mg/kg):

- 软饮料:7.8

- 冷饮:14

- 糖果:17

- 焙烤食品:15

- 布丁类:3.7

适度为限(FDA §172.515,2000)。

食品添加剂最大允许使用量及最大允许残留量标准| 添加剂中文名称 | 允许使用该种添加剂的食品中文名称 | 添加剂功能 | 最大允许使用量(g/kg) | 最大允许残留量(g/kg) |

|---|---|---|---|---|

| 己酸异戊酯 | 食品 | 食品用香料 | 用于配制香精的各香料成分不得超过在GB 2760中的最大允许使用量和最大允许残留量 |

无色液体,具有苹果和菠萝般的香气。沸点为222℃,闪点88℃。溶于乙醇、非挥发性油和矿物油,不溶于丙二醇、水和甘油。

天然存在于葡萄酒和橙皮中。

用途GB 2760—96规定为允许使用的食用香料,主要用于配制苹果、香蕉、菠萝和朗姆酒等型香精。

生产方法反应信息

-

作为产物:参考文献:名称:Lipase-Catalyzed Synthesis of Ethyl Hexanoate in Microemulsion System摘要:本文研究了在十二烷基苯磺酸/异辛烷/水微乳液体系中脂肪酶催化合成己酸乙酯的过程。研究了多种参数对酯化反应的影响,包括w0([H2O]/[表面活性剂])值、反应时间、反应温度、油相溶剂以及微乳液体系中的缓冲溶液pH值。结果表明,合成己酸乙酯的最佳实验条件为:w0 = 4,反应时间4小时,反应温度40 ºC,缓冲溶液pH值为7。在这些条件下,己酸乙酯的转化率可达到98.5%。在十二烷基苯磺酸反向微乳液体系中,脂肪酶催化合成己酸乙酯具有三重机制,即酸催化、微乳液催化和酶催化。DOI:10.14233/ajchem.2013.15126

文献信息

-

[EN] PROCESSES FOR PRODUCING CARBOXYLIC ACIDS<br/>[FR] PROCÉDÉS DE PRODUCTION D'ACIDES CARBOXYLIQUES申请人:EASTMAN CHEM CO公开号:WO2020205348A1公开(公告)日:2020-10-08Processes are disclosed for preparing carboxylic acids from organic esters, the processes comprising contacting an ester with water in the presence of an acid catalyst and a homogenizing solvent at conditions effective to form a carboxylic acid. The homogenizing solvent is present in an amount sufficient to form a single-phase reaction mixture comprising the ester, water, and homogenizing solvent. The homogenizing solvent may be selected from acetonitrile, dimethyl sulfoxide, and 1,4-dioxane.

-

Active-releasing cyclic siloxanes申请人:Perry J. Robert公开号:US20050136021A1公开(公告)日:2005-06-23Cyclic siloxanes that contain releasable active ingredients are described. The active ingredient can be an alcohol or enolizable carbonyl-containing compound such as a ketone, aldehyde, or ester. The product siloxanes are useful in a variety of personal and household care products where slow or controlled release of active ingredient is desired. A preferred embodiment utilizes substituents that when released as active ingredients are fragrant.

-

Cyclic siloxane compositions for the release of active ingredients申请人:Perry J. Robert公开号:US20050136022A1公开(公告)日:2005-06-23Cyclic siloxanes that contain releasable active ingredients are described. The active ingredient can be an alcohol or enolizable carbonyl-containing compound such as a ketone, aldehyde, or ester. The product siloxanes are useful in a variety of personal and household care products where slow or controlled release of active ingredient is desired. A preferred embodiment utilizes substituents that when released as active ingredients are fragrant.

-

COMPOSITION CONTAINING REDUCED COENZYME Q10, AND MANUFACTURING AND STABILISING METHODS THEREFOR申请人:Yamaguchi Takao公开号:US20130142767A1公开(公告)日:2013-06-06The present invention relates to a method of producing reduced coenzyme Q10, including reducing oxidized coenzyme Q10 using a reducing agent in terpenes that can highly dissolve oxidized coenzyme Q10 and reduced coenzyme Q10 in the co-existence of at least one kind of additive selected from the group consisting of alcohols, water, a surfactant and diacylglycerol. In addition, the present invention relates to a composition comprising terpenes, a reducing agent, reduced coenzyme Q10 and at least one kind selected from the group consisting of alcohols, water, a surfactant and diacylglycerol, and a method of stabilizing reduced coenzyme Q10 comprising preparing the composition.

-

Polymerizable composition, optical material comprising the composition and method for producing the material申请人:——公开号:US20040254258A1公开(公告)日:2004-12-16A cured matter obtained by polymerizing and curing a polymerizable composition comprising a compound having at least one episulfide in a molecule is reduced in an odor by adding a perfume to the polymerizable composition comprising the compound having at least one episulfide in a molecule. A cloudiness of the lens is removed by raising a purity of sulfur to 98% or more. A reduction in a chlorine content of the sulfur compound described above to 0.1% by weight or less elevates an oxidation resistance and a light fastness of the high refractive index optical material and improves a color tone thereof. An optical product having a high refractive index and a high-degree transparency is provided by subjecting the composition in advance to deaerating treatment at 0 to 100° C. for one minute to 24 hours under a reduced pressure of 0.001 to 50 torr.

表征谱图

-

氢谱1HNMR

-

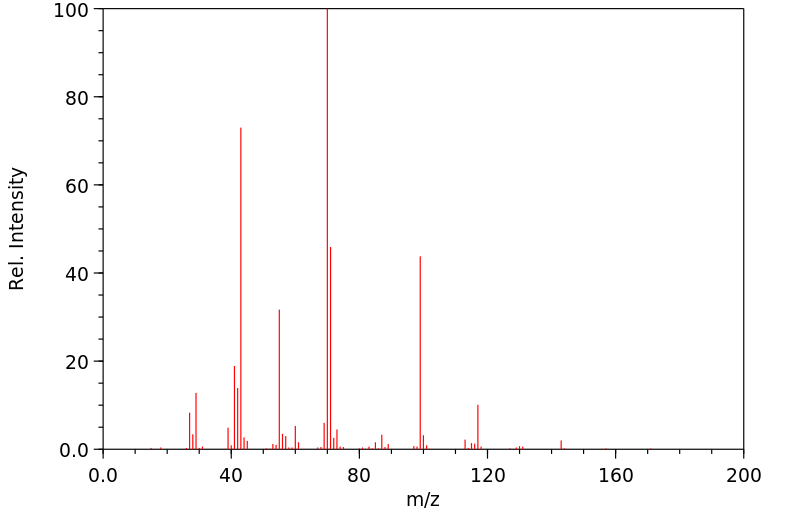

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(±)17,18-二HETE

(±)-辛酰肉碱氯化物

(Z)-5-辛烯甲酯

(Z)-4-辛烯酸

(R)-甲羟戊酸锂盐

(R)-普鲁前列素,游离酸

(R,R)-半乳糖苷

(E)-4-庚烯酸

(E)-4-壬烯酸

(E)-4-十一烯酸

(9Z,12E)-十八烷二烯酸甲酯

(6E)-8-甲基--6-壬烯酸甲基酯-d3

(3R,6S)-rel-8-[2-(3-呋喃基)-1,3-二氧戊环-2-基]-3-羟基-2,6-二甲基-4-辛酮

龙胆二糖

黑曲霉二糖

黄质霉素

麦芽酮糖一水合物

麦芽糖醇

麦芽糖酸

麦芽糖基蔗糖

麦芽糖一水合物

麦芽糖

鳄梨油酸乙酯

鲸蜡醇蓖麻油酸酯

鲸蜡醇油酸酯

鲸蜡硬脂醇硬脂酸酯

鲸蜡烯酸脂

鲸蜡基花生醇

鲫鱼酸

鲁比前列素

鲁比前列素

高级烷基C16-18-醇

高甲羟戊酸

高效氯氰菊酯

高-gamma-亚油酸

马来酸烯丙酯

马来酸氢异丙酯

马来酸氢异丁酯

马来酸氢丙酯

马来酸氢1-[2-(2-羟基乙氧基)乙基]酯

马来酸单乙酯

马来酸单丁酯

马来酸二辛酯

马来酸二癸酯

马来酸二甲酯

马来酸二烯丙酯

马来酸二正丙酯

马来酸二戊基酯

马来酸二异壬酯

马来酸二异丙酯