二丁基乙烯基-膦 | 13652-22-7

中文名称

二丁基乙烯基-膦

中文别名

——

英文名称

Di-n-butyl-vinyl-phosphin

英文别名

Dibutyl-vinyl-phosphin;Vinyl-dibutyl-phosphin;Phosphine, dibutylvinyl-;dibutyl(ethenyl)phosphane

CAS

13652-22-7

化学式

C10H21P

mdl

——

分子量

172.25

InChiKey

CQOGRDZYCMHKKE-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:48-49 °C(Press: 2 Torr)

-

密度:0.8210 g/cm3

计算性质

-

辛醇/水分配系数(LogP):2.9

-

重原子数:11

-

可旋转键数:7

-

环数:0.0

-

sp3杂化的碳原子比例:0.8

-

拓扑面积:0

-

氢给体数:0

-

氢受体数:0

安全信息

-

海关编码:2901299090

SDS

上下游信息

-

下游产品

中文名称 英文名称 CAS号 化学式 分子量 —— Vinyl-dibutyl-phosphinoxid 4569-33-9 C10H21OP 188.25

反应信息

-

作为反应物:参考文献:名称:Issleib,K.; Weichmann,H., Zeitschrift fur Chemie, 1971, vol. 11, p. 188 - 189摘要:DOI:

-

作为产物:参考文献:名称:3d-Orbital Resonance in Trivalent Organophosphines. II. Additions of Organolithium Compounds to Vinylphosphines1摘要:DOI:10.1021/jo01341a503

文献信息

-

Process and plant for manufacturing polyethylene-diene-copolymers申请人:Borealis AG公开号:EP2636691A1公开(公告)日:2013-09-11The present invention provides a process for manufacturing polyethylene-diene-copolymer conducted in a plant comprising at least one compressor unit (10), at least one preheater unit (20) being downstream of the compressor unit (10) and at least one reactor (30), in particular a reactor, being downstream of the compressor unit (10) and the preheater unit (20) a) Feeding a first feed stream (1) comprising ethylene into the at least one compressor unit (10) and subsequently into the at least one preheater unit (20), b1) Feeding a second feed stream (2) comprising at least one diene comonomer to the first feed stream (1) leaving the at least preheater unit (20), and feeding the combined feed streams (4) comprising ethylene and the at least one diene comonomer to the at least one reactor (30), and/or b2) Feeding a second feed stream (2) comprising at least one diene comonomer to the at least one reactor (30) at at least one location along the reactor (30).本发明提供了一种在工厂中生产聚乙烯-二烯-共聚物的工艺,该工厂包括至少一个压缩机组(10)、位于压缩机组(10)下游的至少一个预热器组(20)以及位于压缩机组(10)和预热器组(20)下游的至少一个反应器(30),特别是反应器 a) 将包含乙烯的第一原料流(1)送入至少一个压缩机组(10),随后送入至少一个预热器组(20)、b1) 将包含至少一种二烯单体的第二原料流 (2) 喂入离开至少一个预热器单元 (20) 的第一原料流 (1),并将包含乙烯和至少一种二烯单体的合并原料流 (4) 喂入至少一个反应器 (30),和/或 b2) 在反应器 (30) 的至少一个位置将包含至少一种二烯单体的第二原料流 (2) 喂入至少一个反应器 (30)。

-

Weichmann, H.; Quell, G.; Tzschach, A., Zeitschrift fur Anorganische und Allgemeine Chemie作者:Weichmann, H.、Quell, G.、Tzschach, A.DOI:——日期:——

-

Diorganophosphinoalkyl-dimethylzinnchloride: Synthese, struktur und reaktionsverhalten作者:H. WeichmannDOI:10.1016/s0022-328x(00)99156-3日期:1984.2

-

Kabachnik,A.M.I. et al., Doklady Chemistry, 1960, vol. 135, p. 1309 - 1311作者:Kabachnik,A.M.I. et al.DOI:——日期:——

-

PROCESS AND PLANT FOR MANUFACTURING POLYETHYLENE-DIENE-COPOLYMERS申请人:Borealis AG公开号:EP2822979A1公开(公告)日:2015-01-14

表征谱图

-

氢谱1HNMR

-

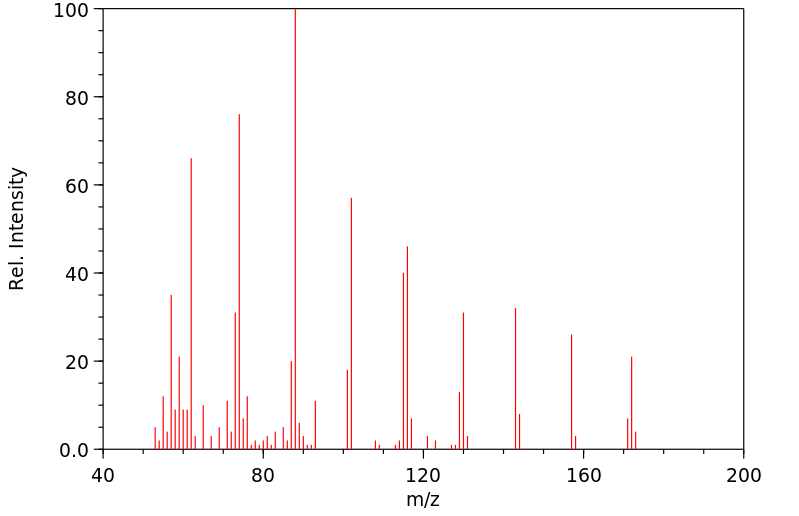

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

顺-二氯双(三乙基膦)铂(II)

镍,二氯二[三(2-甲基丙基)膦]-

铂(三乙基膦)4

辛基二丁基氧膦

辛基[二(2,4,4-三甲代戊基)]磷烷氧化

膦,(1-甲基-1,2-乙二基)二[二(1-甲基乙基)-

羰基氯氢[双(2-二-异丙基膦酰基乙基)胺]钌(II)

羰基氯氢[二(2-二环己基膦基乙基)胺]钌(II)

羰基氯氢[二(2-二叔丁基膦乙基)胺]钌(II)

硅烷,三环己基-

癸基二辛基氧化膦

甲基双(羟甲基)膦

甲基二辛基氧膦

甲基二乙基膦

甲基(二丙基)膦

环戊基二戊基氧膦

环己基双十八烷基膦

环己基双十二烷基膦

环己基二辛基膦

环己基二异丁基氧膦

环己基二己基膦氧化物

环己基二己基膦

环己基二叔丁基膦

烯丙基乙烯基膦酸

氯甲基(二甲基)氧膦

氯化二氢[双(2-di-i-丙基膦酰乙基)胺]铱(III)

氯化(双三环己基膦)(一氧化碳)(氢)钌

氯代三叔丁基磷化金(I)

氯(三甲基膦)金

氯(三乙基膦)金(I)

氨合二氯(1-(二甲基亚膦酰)甲胺-N)铂

氧化膦,亚甲基二[二甲基-

氧化膦,二丁基乙基-

氧化膦,二(碘甲基)甲基-

氧化膦,三十六烷基-

氧化膦,三(癸基)-

正丁基二(1-金刚烷基)膦

替曲膦

叔丁基双(2,2-二甲基丙基)膦

叔丁基二环己基膦

叔丁基二异丙基膦

叔丁基二乙基膦

叔丁基(二甲基)膦

双异丁基丁基磷烷

双[2-(二环己基)乙基]胺

双[2-(二-叔丁基膦基)乙基]胺

双[2-(二异丙基膦基)乙基]胺

双[2-(二叔丁基膦)乙胺]二氯化钌

双[1,3-双(二异丙基膦)丙烷]钯

双(羟甲基)甲基膦氧化物