5-Iodo-1,2,3,4-tetramethylcyclopentadiene | 351023-46-6

中文名称

——

中文别名

——

英文名称

5-Iodo-1,2,3,4-tetramethylcyclopentadiene

英文别名

5-Iodo-1,2,3,4-tetramethylcyclopenta-1,3-diene

CAS

351023-46-6

化学式

C9H13I

mdl

——

分子量

248.107

InChiKey

UNOANOINZHEHEF-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

计算性质

-

辛醇/水分配系数(LogP):2.1

-

重原子数:10

-

可旋转键数:0

-

环数:1.0

-

sp3杂化的碳原子比例:0.56

-

拓扑面积:0

-

氢给体数:0

-

氢受体数:0

反应信息

-

作为反应物:描述:lithio-1,1-bis(4,4-dimethyl-2-oxazolinyl)ethane 、 5-Iodo-1,2,3,4-tetramethylcyclopentadiene 反应 8.0h, 以68%的产率得到1,1-bis(4,4-dimethyl-2-oxazolinyl)-1-(tetramethylcyclopentadiene)ethane参考文献:名称:Cyclopentadienyl-bis(oxazoline) Magnesium and Zirconium Complexes in Aminoalkene Hydroaminations摘要:A new class of cyclopentadiene-bis(oxazoline) compounds and their piano-stool-type organometallic complexes have been prepared as catalysts for hydroamination of aminoalkenes. The two compounds MeC(Ox(Me2))(2)C5H5 (Bo(M)CpH; Ox(Me2) = 4,4-dimethyl-2-oxazoline) and MeC-(Ox(Me2))(2)C5Me4H (Bo(M)Cp(tet)H ) are synthesized from C5R4HI (R = H, Me) and MeC(Ox(Me2))(2)Li. These cyclopentadiene-bis(oxazolines) are converted into ligands that support a variety of metal centers in piano-stool-type geometries, and here we report the preparation of Mg, Tl, Ti, and Zr compounds. Bo(M)CpH and Bo(M)Cp(tet)H react with MgMe2(O2C4H2)(2) to give the magnesium methyl complexes {Bo(M)Cp}MgMe and {Bo(M)Cp(tet)}MgMe. Bo(M)CpH and Bo(M)Cp(tet)H are converted to Bo(M)CpTl and Bo(M)Cp(tet)Tl by reaction with TIOEt. The thallium derivatives react with TiCl3(THF)(3) to provide [{Bo(M)Cp}TiCl(mu-Cl)](2) and [{Bo(M)Cp(tet)}TiCl(mu-Cl)](2), the former of which is crystallographically characterized as a dimeric species. Bo(M)CpH and Zr(NMe2)(4) react to eliminate dimethylamine and afford {Bo(M)Cp}Zr(NMe2)(3), which is crystallographically characterized as a monomeric four-legged piano-stool compound. {Bo(M)Cp}Zr(NMe2)(3), {Bo(M)Cp}MgMe, and {Bo(M)Cp(tet)}MgMe are efficient catalysts for the hydroamination/cyclization of aminoalkenes under mild conditions.DOI:10.1021/acs.organomet.5b00771

-

作为产物:描述:lithium tetramethylcyclopentadienide 在 碘 作用下, 以 正戊烷 为溶剂, 反应 12.0h, 以96%的产率得到5-Iodo-1,2,3,4-tetramethylcyclopentadiene参考文献:名称:Methylated Dihydropentafulvalenes and Pentafulvalenides from Tetramethylcyclopentadiene Derivatives摘要:分别用CuCl2或溴代四甲基环戊二烯(4)处理四甲基环戊二烯锂(1Li),以及锡化四甲基环戊二烯与4在PdBr2的存在下反应,得到两种异构体八甲基二氢五氟戊烯(3和5),其中5被去质子化为高度取代的环戊二烯阴离子。1Li转化为碘代四甲基环戊二烯(7),7与环戊二烯阴离子反应,根据条件不同,得到三种八甲基二氢五氟戊烯的互变异构体(8a、8b和8c)或仅得到8a。3和8a的晶体结构已经确定,8的异构体已经转化为相应的二阴离子。DOI:10.1055/s-2001-12769

文献信息

-

Producing polyolefin products申请人:Univation Technologies, LLC公开号:US10239977B2公开(公告)日:2019-03-26Catalyst systems and methods for making and using the same are described. A method includes selecting a catalyst blend using a blend polydispersity index (bPDI) map. The polydispersity map is generated by generating a number of polymers for at least two catalysts. Each polymer is generated at a different hydrogen to ethylene ratio. At least one catalyst generates a higher molecular weight polymer and another catalyst generates a lower molecular weight polymer. A molecular weight for each polymer is measured. The relationship between the molecular weight of the polymers generated by each of the catalysts and the ratio of hydrogen to ethylene is determined. A family of bPDI curves for polymers that would be made using a number of ratios of a blend of the at least two catalysts for each of a number of ratios of hydrogen to ethylene. A ratio for the catalyst blend of the catalysts that generates a polymer having a bPDI that matches a polymer fabrication process is selected, and the product specific polyolefin is made using the catalyst blend.

-

PRODUCING POLYOLEFIN PRODUCTS申请人:UNIVATION TECHNOLOGIES ,LLC公开号:US20170183433A1公开(公告)日:2017-06-29Catalyst systems and methods for making and using the same. A method of methylating a catalyst composition while substantially normalizing the entiomeric distribution is provided. The method includes slurrying the organometallic compound in dimethoxyethane (DME), and adding a solution of RMgBr in DME, wherein R is a methyl group or a benzyl group, and wherein the RMgBr is greater than about 2.3 equivalents relative to the organometallic compound. After the addition of the RMgBr, the slurry is mixed for at least about four hours. An alkylated organometallic is isolated, wherein the methylated species has a meso/rac ratio that is between about 0.9 and about 1.2.

-

SILICON-BASED ENERGY STORAGE DEVICES WITH SILICON CONTAINING ELECTROLYTE ADDITIVES申请人:Enevate Corporation公开号:US20200388876A1公开(公告)日:2020-12-10Electrolytes and electrolyte additives for energy storage devices comprising a silicon compound are disclosed. The energy storage device comprises a first electrode and a second electrode, wherein at least one of the first electrode and the second electrode is a Si-based electrode, a separator between the first electrode and the second electrode, an electrolyte, and at least one electrolyte additive selected from a silicon compound.

-

METHOD TO PREPARE ETHYLENE COPOLYMERS申请人:Univation Technologies, LLC公开号:US20210024670A1公开(公告)日:2021-01-28Catalyst systems and methods for making and using the same. A method of polymerizing olefins to produce a polyolefin polymer with a multimodal composition distribution, includes contacting ethylene and a comonomer with a catalyst system. The catalyst system includes a first catalyst compound and a second catalyst compound that are co-supported to form a commonly supported catalyst system. The first catalyst compound includes a compound with the general formula (C 5 H a R 1 b )(C 5 H c R 2 d )HfX 2 . The second catalyst compound includes at least one of the following general formulas: In both catalyst systems, the R groups can be independently selected from any number of substituents, including, for example, H, a hydrocarbyl group, a substituted hydrocarbyl group, or a heteroatom group, among others.

-

US9879106B2申请人:——公开号:US9879106B2公开(公告)日:2018-01-30

表征谱图

-

氢谱1HNMR

-

质谱MS

-

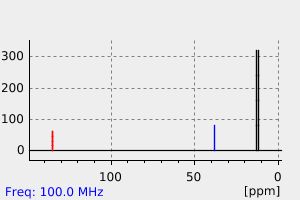

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

顺式-3-甲基-1,2,3,4-四氯-1-丁烯

顺式-1-溴-1-丙烯

顺式-1-氯-1-丁烯

顺式-1,3-二氯丙烯

顺式-1,2-二碘乙烯

顺式-1,2-二溴乙烯

顺式-1,2-二氟-1-氯乙烯

顺-氯丹

顺-九氯

顺-九氯

顺-1-溴-2-乙氧基乙烯

顺-1,2-二氯乙烯

顺-1,2,4-三氯-3-甲基-2-丁烯

顺,顺-1,2,3,4-四氯-1,3-丁二烯

除螨灵

锗烷,(1-溴-1,2-丙二烯基)三甲基-

锌,氯(三氟乙烯基)-

铜(1+),1,1,2-三氟乙烯

苯甲酸,4-[(1E)-2-[[(4-氯苯基)甲基]磺酰]乙烯基]-

苯并烯氟菌唑中间体

艾日布林-2碘

聚(乙烯-氯代三氟乙烯)

碳化镁碘化物

碘化乙烯

硫丹醇

硅烷,二氯(2-氯乙烯基)甲基-

硅烷,[2-(碘亚甲基)己基]三甲基-,(Z)-

甲碘乙烯

甲氧基全氟丁烷-反式-1,2-二氯乙烯1:1共沸物

甲基烯丙基溴化镁

甲基全氟-1-甲基-2-丙烯基醚

甲基全氟-1-丁基-1-丙烯基醚

甲基全氟-1-丁基-1-丙烯基醚

环丙烷,1,1-二氯-2-(3,3-二氯-2-甲基-2-丙烯基)-2,3,3-三甲基-

环丙烯,1,2-二氟-

特比萘芬杂质

溴西克林

溴甲基烯酮

溴环辛四烯

溴氯丙烯

溴代三氟代乙烯

溴亚甲基环己烷

溴乙烯

溴三碘乙烯

氰尿酰氟

氯磺酸三氟乙烯基酯

氯化聚乙烯

氯乙烯与异丁基乙烯醚共聚物

氯乙烯与三氯乙烯聚合物

氯乙烯-d3