异氰酸异丁酯 | 1873-29-6

中文名称

异氰酸异丁酯

中文别名

異氰酸異丁酯;1-异氰酰基-2-甲基丙烷

英文名称

isobutyl isocyanate

英文别名

1-isocyanato-2-methylpropane;Isobutylisocyanat

CAS

1873-29-6

化学式

C5H9NO

mdl

MFCD00036022

分子量

99.1326

InChiKey

NNZVKALEGZPYKL-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

熔点:85.5°C (estimate)

-

沸点:125.62°C (estimate)

-

密度:0.9570 (estimate)

-

物理描述:Isobutyl isocyanate appears as a colorless liquid. Less dense than water. Contact may severely irritate skin, eyes and mucous membranes. May be very toxic by ingestion, inhalation and skin absorption. Used to make pesticides and pharmaceuticals.

计算性质

-

辛醇/水分配系数(LogP):2.3

-

重原子数:7

-

可旋转键数:2

-

环数:0.0

-

sp3杂化的碳原子比例:0.8

-

拓扑面积:29.4

-

氢给体数:0

-

氢受体数:2

安全信息

-

危险等级:3.1

-

危险品运输编号:UN 2486

-

海关编码:2929109000

-

包装等级:II

-

危险类别:3.1

SDS

反应信息

-

作为反应物:描述:异氰酸异丁酯 在 sodium methylate 作用下, 以 甲醇 、 甲苯 为溶剂, 反应 112.0h, 生成 3-isobutyl-6-(4-methoxyphenyl)-5-methylthieno[2,3-d]pyrimidine-2,4(1H,3H)-dione参考文献:名称:发现在6-位带有对甲氧基脲基苯基部分的噻吩并[2,3-d]嘧啶-2,4-二酮:一种用于人类促黄体生成激素释放激素受体的高效且可口服生物利用的非肽拮抗剂。摘要:我们先前已经公开了第一种有效且口服有效的非肽类抗人黄体生成激素释放激素(LHRH)受体,即噻吩并[2,3-b]吡啶-4-酮衍生物T-98475(1)。已经通过采用用其他杂环代用品替代噻吩并吡啶-4-酮核的策略对开发非肽LHRH拮抗剂进行了广泛的研究。我们在本文中描述了一系列含有联芳基部分的噻吩并[2,3-d]嘧啶-2,4-二酮衍生物的设计和合成,这些衍生物导致发现了一种高效且口服活性的非肽LHRH拮抗剂, 5-(N-苄基-N-甲基氨基甲基)-1-(2,6-二氟苄基)-6- [4-(3-甲氧基脲基)苯基] -3-苯基噻吩并[2,3-d]嘧啶-2, 4(1H,3H)-二酮(9k:TAK-013)。化合物9k对人受体显示出高结合亲和力和有效的体外拮抗活性,其最大抑制浓度(IC(50))值分别为0.1和0.06 nM。口服9k能够以30 mg / kg的剂量在cast割的雄性食蟹猕猴中几乎完全抑制DOI:10.1021/jm020180i

-

作为产物:参考文献:名称:发现在6-位带有对甲氧基脲基苯基部分的噻吩并[2,3-d]嘧啶-2,4-二酮:一种用于人类促黄体生成激素释放激素受体的高效且可口服生物利用的非肽拮抗剂。摘要:我们先前已经公开了第一种有效且口服有效的非肽类抗人黄体生成激素释放激素(LHRH)受体,即噻吩并[2,3-b]吡啶-4-酮衍生物T-98475(1)。已经通过采用用其他杂环代用品替代噻吩并吡啶-4-酮核的策略对开发非肽LHRH拮抗剂进行了广泛的研究。我们在本文中描述了一系列含有联芳基部分的噻吩并[2,3-d]嘧啶-2,4-二酮衍生物的设计和合成,这些衍生物导致发现了一种高效且口服活性的非肽LHRH拮抗剂, 5-(N-苄基-N-甲基氨基甲基)-1-(2,6-二氟苄基)-6- [4-(3-甲氧基脲基)苯基] -3-苯基噻吩并[2,3-d]嘧啶-2, 4(1H,3H)-二酮(9k:TAK-013)。化合物9k对人受体显示出高结合亲和力和有效的体外拮抗活性,其最大抑制浓度(IC(50))值分别为0.1和0.06 nM。口服9k能够以30 mg / kg的剂量在cast割的雄性食蟹猕猴中几乎完全抑制DOI:10.1021/jm020180i

文献信息

-

Dialkoxy-phosphonyl-N-alkyl-formic acid amides申请人:Bayer Aktiengesellschaft公开号:US04400331A1公开(公告)日:1983-08-23The present invention relates to a process for the preparation of polyurethane foams capable of being flame laminated and high frequency welded, comprising reacting: (a) polyisocyanate, (b) a compound having a molecular weight of from 400 to 10,000 containing at least two isocyanate-reactive hydrogen atoms and (c) a dialkoxy-phosphonyl-N-alkyl-formic acid amide of the formula: ##STR1## wherein m represents an integer of from 1 to 3, n represents an integer of from 0 to 8, X represents halogen, hydrogen, C.sub.1 to C.sub.6 alkyl, -OR, or ##STR2## R represents C.sub.1 to C.sub.6 alkyl, R.sub.1 represents hydrogen, C.sub.1 to C.sub.10 alkyl, C.sub.1 to C.sub.10 alkylene, C.sub.6 to C.sub.10 aryl or C.sub.6 to C.sub.10 arylene, and R.sub.2 and R.sub.3, which may be the same or different, represent C.sub.1 to C.sub.10 alkyl in the presence of water and/or blowing agent. The present invention also relates to dialkoxy-phosphonyl-N-formic acid amides.本发明涉及一种制备聚氨酯泡沫的方法,该泡沫能够进行火焰层压和高频焊接,包括反应:(a)聚异氰酸酯,(b)分子量在400至10,000之间的化合物,含有至少两个异氰酸反应性氢原子,和(c)具有以下结构的二烷氧基磷酰-N-烷基甲酸酰胺:##STR1## 其中m表示1到3的整数,n表示0到8的整数,X表示卤素、氢、C.sub.1到C.sub.6烷基、-OR或##STR2## R表示C.sub.1到C.sub.6烷基,R.sub.1表示氢、C.sub.1到C.sub.10烷基、C.sub.1到C.sub.10亚烷基、C.sub.6到C.sub.10芳基或C.sub.6到C.sub.10芳亚烷基,R.sub.2和R.sub.3,可以相同也可以不同,表示C.sub.1到C.sub.10烷基,在水和/或发泡剂的存在下进行。本发明还涉及二烷氧基磷酰-N-甲酸酰胺。

-

SUBSTITUTED 3-ISOBUTYL-9,10-DIMETHOXY-1,3,4,6,7,11B-HEXAHYDRO-2H-PYRIDO[2,1-a]ISOQUINOLIN-2-OL COMPOUNDS, THEIR SYNTHESIS, AND USE THEREOF申请人:DISPERSOL TECHNOLOGIES, LLC公开号:US20210087191A1公开(公告)日:2021-03-25The invention relates to substituted 3-isobutyl-9,10-dimethoxy-1,3,4,6,7,11b-hexahydro-2H-pyrido[2,1-a]isoquinolin-2-ol compounds, their synthesis, pharmaceutical compositions containing them, and methods of using them in the treatment of disorders benefiting from inhibition of vesicular monoamine transporter 2 (VMAT2).这项发明涉及替代的3-异丁基-9,10-二甲氧基-1,3,4,6,7,11b-六氢-2H-吡啶并[2,1-a]异喹啉-2-醇化合物,它们的合成,含有它们的药物组合物,以及在治疗受益于抑制囊泡单胺转运体2(VMAT2)的紊乱时使用它们的方法。

-

[EN] SUBSTITUTED PYRAZOLO[1,5-A]PYRIDINE COMPOUNDS AS RET KINASE INHIBITORS<br/>[FR] COMPOSÉS SUBSTITUÉS DE PYRAZOLO[1,5-A]PYRIDINE EN TANT QU'INHIBITEURS DE LA KINASE RET申请人:ANDREWS STEVEN W公开号:WO2018071447A1公开(公告)日:2018-04-19Provided herein are compounds of the Formula I and stereoisomers and pharmaceutically acceptable salts or solvates thereof, in which A, B, X1, X2, X3, X4, Ring D, and E have the meanings given in the specification, which are inhibitors of RET kinase and are useful in the treatment and prevention of diseases which can be treated with a RET kinase inhibitor, including RET-associated diseases and disorders.

-

HETEROCYCLYLMETHYL-THIENOURACILE AS ANTAGONISTS OF THE ADENOSINE-A2B-RECEPTOR申请人:BAYER PHARMA AKTIENGESELLSCHAFT公开号:US20180065981A1公开(公告)日:2018-03-08The present application relates to novel thieno[2,3-d]pyrimidine-2,4-dione (“thienouracil”) derivatives bearing a particular type of (azaheterocyclyl)methyl substituent, to processes for the preparation thereof, to the use thereof alone or in combinations for treatment and/or prevention of diseases and to the use thereof for production of medicaments for treatment and/or prevention of diseases, especially for treatment and/or prevention of pulmonary and cardiovascular disorders and of cancer.

-

[EN] SUBSTITUTED PYRAZOLO[1,5-A]PYRIDINE COMPOUNDS AS RET KINASE INHIBITORS<br/>[FR] COMPOSÉS SUBSTITUÉS DE PYRAZOLO[1,5-A]PYRIDINES COMME INHIBITEURS DE LA KINASE RET申请人:ARRAY BIOPHARMA INC公开号:WO2017011776A1公开(公告)日:2017-01-19Provided herein are compounds of the General Formula I: and stereoisomers and pharmaceutically acceptable salts or solvates thereof, in which A, B, D, E, X1, X2, X3 and X4 have the meanings given in the specification, which are inhibitors of RET kinase and are useful in the treatment and prevention of diseases which can be treated with a RET kinase inhibitor, including diseases or disorders mediated by a RET kinase.

表征谱图

-

氢谱1HNMR

-

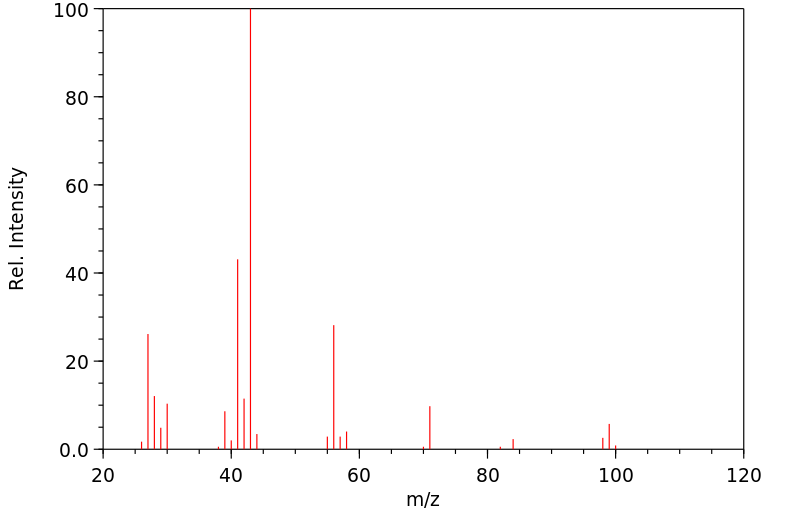

质谱MS

-

碳谱13CNMR

-

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(乙腈)二氯镍(II)

(R)-(-)-α-甲基组胺二氢溴化物

(N-(2-甲基丙-2-烯-1-基)乙烷-1,2-二胺)

(4-(苄氧基)-2-(哌啶-1-基)吡啶咪丁-5-基)硼酸

(11-巯基十一烷基)-,,-三甲基溴化铵

鼠立死

鹿花菌素

鲸蜡醇硫酸酯DEA盐

鲸蜡硬脂基二甲基氯化铵

鲸蜡基胺氢氟酸盐

鲸蜡基二甲胺盐酸盐

高苯丙氨醇

高箱鲀毒素

高氯酸5-(二甲氨基)-1-({(E)-[4-(二甲氨基)苯基]甲亚基}氨基)-2-甲基吡啶正离子

高氯酸2-氯-1-({(E)-[4-(二甲氨基)苯基]甲亚基}氨基)-6-甲基吡啶正离子

高氯酸2-(丙烯酰基氧基)-N,N,N-三甲基乙铵

马诺地尔

马来酸氢十八烷酯

马来酸噻吗洛尔EP杂质C

马来酸噻吗洛尔

马来酸倍他司汀

顺式环己烷-1,3-二胺盐酸盐

顺式氯化锆二乙腈

顺式吡咯烷-3,4-二醇盐酸盐

顺式双(3-甲氧基丙腈)二氯铂(II)

顺式3,4-二氟吡咯烷盐酸盐

顺式1-甲基环丙烷1,2-二腈

顺式-二氯-反式-二乙酸-氨-环己胺合铂

顺式-二抗坏血酸(外消旋-1,2-二氨基环己烷)铂(II)水合物

顺式-N,2-二甲基环己胺

顺式-4-甲氧基-环己胺盐酸盐

顺式-4-环己烯-1.2-二胺

顺式-4-氨基-2,2,2-三氟乙酸环己酯

顺式-3-氨基环丁烷甲腈盐酸盐

顺式-2-羟基甲基-1-甲基-1-环己胺

顺式-2-甲基环己胺

顺式-2-(苯基氨基)环己醇

顺式-2-(苯基氨基)环己醇

顺式-2-(氨基甲基)-1-苯基环丙烷羧酸盐酸盐

顺式-1,3-二氨基环戊烷

顺式-1,2-环戊烷二胺二盐酸盐

顺式-1,2-环戊烷二胺

顺式-1,2-环丁腈

顺式-1,2-双氨甲基环己烷

顺式--N,N'-二甲基-1,2-环己二胺

顺式-(R,S)-1,2-二氨基环己烷铂硫酸盐

顺式-(2-氨基-环戊基)-甲醇

顺-2-戊烯腈

顺-1,3-环己烷二胺

顺-1,3-双(氨甲基)环己烷