1-叔-丁基-3-乙基-5-甲基苯 | 6630-01-9

中文名称

1-叔-丁基-3-乙基-5-甲基苯

中文别名

3-叔丁基-5-乙基甲苯

英文名称

1-ethyl-3-tert-butyl-5-methyl-benzene

英文别名

1-Aethyl-3-tert-butyl-5-methyl-benzol;3-tert-Butyl-5-ethyltoluene;1-tert-butyl-3-ethyl-5-methylbenzene

CAS

6630-01-9

化学式

C13H20

mdl

MFCD00026954

分子量

176.302

InChiKey

URDKTSKLGNWKDB-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

物化性质

-

沸点:71°C/21mmHg

-

密度:0.859±0.06 g/cm3(Predicted)

-

闪点:66°C(lit.)

-

保留指数:1238.3

计算性质

-

辛醇/水分配系数(LogP):4.8

-

重原子数:13

-

可旋转键数:2

-

环数:1.0

-

sp3杂化的碳原子比例:0.538

-

拓扑面积:0

-

氢给体数:0

-

氢受体数:0

安全信息

-

储存条件:室温且干燥

SDS

上下游信息

-

上游原料

中文名称 英文名称 CAS号 化学式 分子量 3-乙基甲苯 1-Methyl-3-ethylbenzene 620-14-4 C9H12 120.194 -

下游产品

中文名称 英文名称 CAS号 化学式 分子量 —— 1-(3-tert-butyl-5-methyl-phenyl)-ethanone 132777-91-4 C13H18O 190.285 5-叔-丁基间甲基苯甲酸 3-tert-butyl-5-methyl-benzoic acid 17484-28-5 C12H16O2 192.258

反应信息

-

作为反应物:描述:参考文献:名称:Isomerization Accompanying the Acetylation of p-t-Butyltoluene摘要:DOI:10.1021/jo01352a004

-

作为产物:描述:参考文献:名称:NITRO MUSKS. III.1 ASYMMETRICAL MUSKS OF THE DINITRO-tert-BUTYL-m-XYLENE SERIES摘要:DOI:10.1021/jo01366a015

文献信息

-

Guaiacol demethoxylation catalyzed by Re2O7 in ethanol作者:Fei Yan、Yushuai Sang、Yunfei Bai、Kai Wu、Kai Cui、Zhe Wen、Fuhang Mai、Zewei Ma、Linhao Yu、Hong Chen、Yongdan LiDOI:10.1016/j.cattod.2019.07.018日期:2020.9Re2O7 is used to convert guaiacol in ethanol at 320 °C. Guaiacol is deoxygenated and alkylated, and the major products are phenol and alkylphenols (including ethylphenol, diethylphenol, diisopropylphenol, di-tert-butylphenol and 2,6-di-tert-butyl-4-ethylphenol), accounting for 97 mol% of all products. Both catechol and phenol are the intermediates of guaiacol demethoxylation. Among the substituents

-

One-pot production of hydrocarbon oil from poly(3-hydroxybutyrate)作者:Shimin Kang、Jian YuDOI:10.1039/c4ra00892h日期:——phosphoric acid (H3PO4) solution at mild temperatures (165–240 °C). PHB and crotonic acid (C4H6O2), a dominant thermal degradation product of PHB, were deoxygenated mainly via decarboxylation, generating similar liquid and gaseous products. Carbon dioxide and propylene were the major products in gas phase with little CO formation. The hydrocarbon oil (C4–C16) is a mixture of alkanes, alkenes, benzenes and聚(3-羟基丁酸酯)(PHB)是许多微生物物种的能量存储材料,并且已被发现是生产可再生烃油的有效原料。在温和的温度(165–240°C)下,在磷酸(H 3 PO 4)溶液中可获得很高的含油量(高达38.2 wt%)。PHB和巴豆酸(C 4 H 6 O 2)是PHB的主要热降解产物,主要通过以下方式脱氧脱羧,生成类似的液体和气体产物。二氧化碳和丙烯是气相的主要产物,几乎没有一氧化碳的形成。烃油(C4-C16)是烷烃,烯烃,苯和萘的混合物。芳香族化合物(C10–C15)是100 wt%H 3 PO 4溶液中的主要烃,而稀释溶液(50 wt%至85 wt%H 3 PO 4)中则优选烯烃和烷烃(C4-C9 )。H 3 PO 4的浓度是影响油的组成和产率的关键因素。巴豆酸在220°C下高效脱羧3小时,导致70.8 wt%的氧气作为CO 2被去除碳的57.0重量%作为烃油被回收。H 3 PO 4溶液可

表征谱图

-

氢谱1HNMR

-

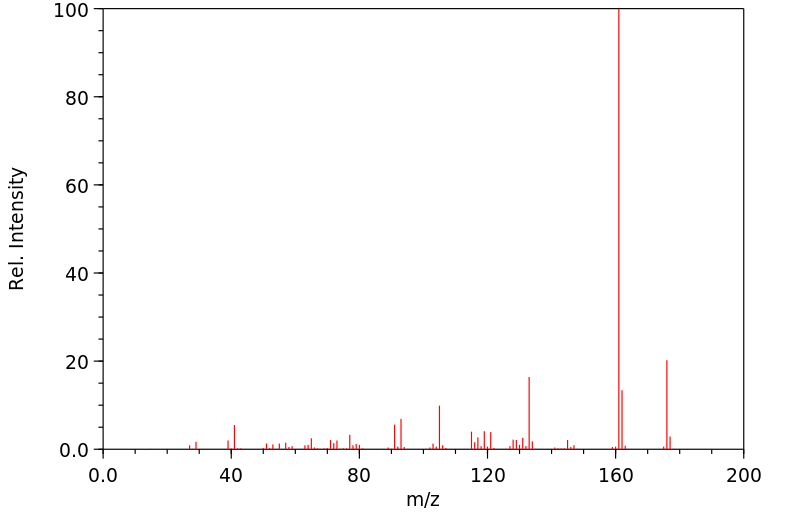

质谱MS

-

碳谱13CNMR

-

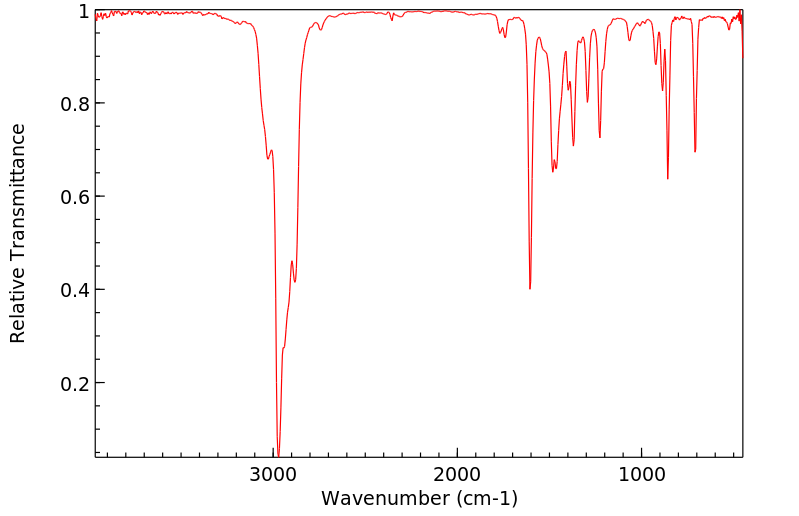

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(βS)-β-氨基-4-(4-羟基苯氧基)-3,5-二碘苯甲丙醇

(S,S)-邻甲苯基-DIPAMP

(S)-(-)-7'-〔4(S)-(苄基)恶唑-2-基]-7-二(3,5-二-叔丁基苯基)膦基-2,2',3,3'-四氢-1,1-螺二氢茚

(S)-盐酸沙丁胺醇

(S)-3-(叔丁基)-4-(2,6-二甲氧基苯基)-2,3-二氢苯并[d][1,3]氧磷杂环戊二烯

(S)-2,2'-双[双(3,5-三氟甲基苯基)膦基]-4,4',6,6'-四甲氧基联苯

(S)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(R)富马酸托特罗定

(R)-(-)-盐酸尼古地平

(R)-(-)-4,12-双(二苯基膦基)[2.2]对环芳烷(1,5环辛二烯)铑(I)四氟硼酸盐

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[((6-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(4-叔丁基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(3-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-4,7-双(3,5-二-叔丁基苯基)膦基-7“-[(吡啶-2-基甲基)氨基]-2,2”,3,3'-四氢1,1'-螺二茚满

(R)-3-(叔丁基)-4-(2,6-二苯氧基苯基)-2,3-二氢苯并[d][1,3]氧杂磷杂环戊烯

(R)-2-[((二苯基膦基)甲基]吡咯烷

(R)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(N-(4-甲氧基苯基)-N-甲基-3-(1-哌啶基)丙-2-烯酰胺)

(5-溴-2-羟基苯基)-4-氯苯甲酮

(5-溴-2-氯苯基)(4-羟基苯基)甲酮

(5-氧代-3-苯基-2,5-二氢-1,2,3,4-oxatriazol-3-鎓)

(4S,5R)-4-甲基-5-苯基-1,2,3-氧代噻唑烷-2,2-二氧化物-3-羧酸叔丁酯

(4S,4''S)-2,2''-亚环戊基双[4,5-二氢-4-(苯甲基)恶唑]

(4-溴苯基)-[2-氟-4-[6-[甲基(丙-2-烯基)氨基]己氧基]苯基]甲酮

(4-丁氧基苯甲基)三苯基溴化磷

(3aR,8aR)-(-)-4,4,8,8-四(3,5-二甲基苯基)四氢-2,2-二甲基-6-苯基-1,3-二氧戊环[4,5-e]二恶唑磷

(3aR,6aS)-5-氧代六氢环戊基[c]吡咯-2(1H)-羧酸酯

(2Z)-3-[[(4-氯苯基)氨基]-2-氰基丙烯酸乙酯

(2S,3S,5S)-5-(叔丁氧基甲酰氨基)-2-(N-5-噻唑基-甲氧羰基)氨基-1,6-二苯基-3-羟基己烷

(2S,2''S,3S,3''S)-3,3''-二叔丁基-4,4''-双(2,6-二甲氧基苯基)-2,2'',3,3''-四氢-2,2''-联苯并[d][1,3]氧杂磷杂戊环

(2S)-(-)-2-{[[[[3,5-双(氟代甲基)苯基]氨基]硫代甲基]氨基}-N-(二苯基甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[((1S,2S)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[[((1R,2R)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2-硝基苯基)磷酸三酰胺

(2,6-二氯苯基)乙酰氯

(2,3-二甲氧基-5-甲基苯基)硼酸

(1S,2S,3S,5S)-5-叠氮基-3-(苯基甲氧基)-2-[(苯基甲氧基)甲基]环戊醇

(1S,2S,3R,5R)-2-(苄氧基)甲基-6-氧杂双环[3.1.0]己-3-醇

(1-(4-氟苯基)环丙基)甲胺盐酸盐

(1-(3-溴苯基)环丁基)甲胺盐酸盐

(1-(2-氯苯基)环丁基)甲胺盐酸盐

(1-(2-氟苯基)环丙基)甲胺盐酸盐

(1-(2,6-二氟苯基)环丙基)甲胺盐酸盐

(-)-去甲基西布曲明

龙蒿油

龙胆酸钠

龙胆酸叔丁酯

龙胆酸

龙胆紫-d6

龙胆紫