(2-nitro-phenyl)-carbamic acid propyl ester | 90870-22-7

中文名称

——

中文别名

——

英文名称

(2-nitro-phenyl)-carbamic acid propyl ester

英文别名

(2-Nitro-phenyl)-carbamidsaeure-propylester;o-Nitro carbanilic acid, n-propyl ester;propyl N-(2-nitrophenyl)carbamate

CAS

90870-22-7

化学式

C10H12N2O4

mdl

——

分子量

224.216

InChiKey

UQXHVOOECLQQHK-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

计算性质

-

辛醇/水分配系数(LogP):3

-

重原子数:16

-

可旋转键数:4

-

环数:1.0

-

sp3杂化的碳原子比例:0.3

-

拓扑面积:84.2

-

氢给体数:1

-

氢受体数:4

反应信息

-

作为产物:描述:参考文献:名称:Hoeke, Recueil des Travaux Chimiques des Pays-Bas, 1935, vol. 54, p. 505,507,513摘要:DOI:

文献信息

-

PRODUCTION METHOD OF CARBAMIC ACID ESTER申请人:NATIONAL INSTITUTE OF ADVANCED INDUSTRIAL SCIENCE AND TECHNOLOGY公开号:US20190185420A1公开(公告)日:2019-06-20A method of production of carbamic acid ester has a high yield and high selectivity and is superior in economy. The method of production of a carbamic acid ester includes reacting an amine, carbon dioxide, and an alkoxysilane compound in the presence of a catalyst containing a zinc compound or an alkali metal compound or in the presence of an ionic liquid. A carbamic acid ester is produced, for example by reacting aniline, carbon dioxide, and tetramethoxysilane at a temperature of 150 to 180° C. in the presence of zinc acetate and 2,2′-bipyridine.

-

Effect of successive increase in alcohol chains on reaction with isocyanates and isothiocyanates作者:Shahnaz Perveen、Arfa Yasmin、Khalid Mohammed KhanDOI:10.1080/14786410802270738日期:2010.1.10The reaction of isocyanates and isothiocyanates with long-chain alcohols, e.g. n-hexanol, n-heptanol and n-octanol, exclusively gave N-aryl-O-alkyl carbamates, while N-aryl-O-alkyl carbamates were formed along with symmetrical 1,3-disubstituted ureas and thioureas when the same reactions were carried out with small-chain alcohols at room temperature without using any solvent.

-

METHOD FOR PRODUCING CARBAMIC ACID ESTER申请人:National Institute of Advanced Industrial Science and Technology公开号:EP3508473A1公开(公告)日:2019-07-10A method of production of carbamic acid ester has a high yield and high selectivity and is superior in economy. The method of production of a carbamic acid ester includes reacting an amine, carbon dioxide, and an alkoxysilane compound in the presence of a catalyst containing a zinc compound or an alkali metal compound or in the presence of an ionic liquid. A carbamic acid ester is produced, for example by reacting aniline, carbon dioxide, and tetramethoxysilane at a temperature of 150 to 180°C in the presence of zinc acetate and 2,2'-bipyridine.

-

Production method of carbamic acid ester申请人:NATIONAL INSTITUTE OF ADVANCED INDUSTRIAL SCIENCE AND TECHNOLOGY公开号:US10752579B2公开(公告)日:2020-08-25A method of production of carbamic acid ester has a high yield and high selectivity and is superior in economy. The method of production of a carbamic acid ester includes reacting an amine, carbon dioxide, and an alkoxysilane compound in the presence of a catalyst containing a zinc compound or an alkali metal compound or in the presence of an ionic liquid. A carbamic acid ester is produced, for example by reacting aniline, carbon dioxide, and tetramethoxysilane at a temperature of 150 to 180° C. in the presence of zinc acetate and 2,2′-bipyridine.

表征谱图

-

氢谱1HNMR

-

质谱MS

-

碳谱13CNMR

-

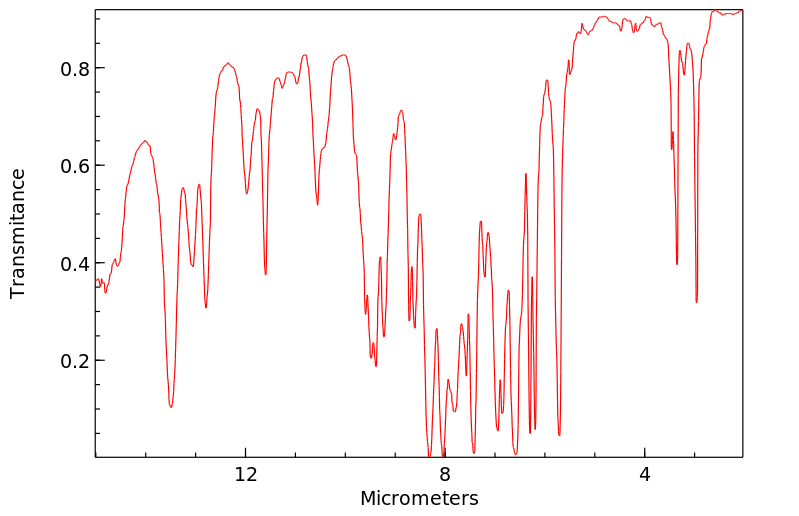

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

(βS)-β-氨基-4-(4-羟基苯氧基)-3,5-二碘苯甲丙醇

(S,S)-邻甲苯基-DIPAMP

(S)-(-)-7'-〔4(S)-(苄基)恶唑-2-基]-7-二(3,5-二-叔丁基苯基)膦基-2,2',3,3'-四氢-1,1-螺二氢茚

(S)-盐酸沙丁胺醇

(S)-3-(叔丁基)-4-(2,6-二甲氧基苯基)-2,3-二氢苯并[d][1,3]氧磷杂环戊二烯

(S)-2,2'-双[双(3,5-三氟甲基苯基)膦基]-4,4',6,6'-四甲氧基联苯

(S)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(R)富马酸托特罗定

(R)-(-)-盐酸尼古地平

(R)-(-)-4,12-双(二苯基膦基)[2.2]对环芳烷(1,5环辛二烯)铑(I)四氟硼酸盐

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[((6-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(4-叔丁基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-7-双(3,5-二叔丁基苯基)膦基7''-[(3-甲基吡啶-2-基甲基)氨基]-2,2'',3,3''-四氢-1,1''-螺双茚满

(R)-(+)-4,7-双(3,5-二-叔丁基苯基)膦基-7“-[(吡啶-2-基甲基)氨基]-2,2”,3,3'-四氢1,1'-螺二茚满

(R)-3-(叔丁基)-4-(2,6-二苯氧基苯基)-2,3-二氢苯并[d][1,3]氧杂磷杂环戊烯

(R)-2-[((二苯基膦基)甲基]吡咯烷

(R)-1-[3,5-双(三氟甲基)苯基]-3-[1-(二甲基氨基)-3-甲基丁烷-2-基]硫脲

(N-(4-甲氧基苯基)-N-甲基-3-(1-哌啶基)丙-2-烯酰胺)

(5-溴-2-羟基苯基)-4-氯苯甲酮

(5-溴-2-氯苯基)(4-羟基苯基)甲酮

(5-氧代-3-苯基-2,5-二氢-1,2,3,4-oxatriazol-3-鎓)

(4S,5R)-4-甲基-5-苯基-1,2,3-氧代噻唑烷-2,2-二氧化物-3-羧酸叔丁酯

(4S,4''S)-2,2''-亚环戊基双[4,5-二氢-4-(苯甲基)恶唑]

(4-溴苯基)-[2-氟-4-[6-[甲基(丙-2-烯基)氨基]己氧基]苯基]甲酮

(4-丁氧基苯甲基)三苯基溴化磷

(3aR,8aR)-(-)-4,4,8,8-四(3,5-二甲基苯基)四氢-2,2-二甲基-6-苯基-1,3-二氧戊环[4,5-e]二恶唑磷

(3aR,6aS)-5-氧代六氢环戊基[c]吡咯-2(1H)-羧酸酯

(2Z)-3-[[(4-氯苯基)氨基]-2-氰基丙烯酸乙酯

(2S,3S,5S)-5-(叔丁氧基甲酰氨基)-2-(N-5-噻唑基-甲氧羰基)氨基-1,6-二苯基-3-羟基己烷

(2S,2''S,3S,3''S)-3,3''-二叔丁基-4,4''-双(2,6-二甲氧基苯基)-2,2'',3,3''-四氢-2,2''-联苯并[d][1,3]氧杂磷杂戊环

(2S)-(-)-2-{[[[[3,5-双(氟代甲基)苯基]氨基]硫代甲基]氨基}-N-(二苯基甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[((1S,2S)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2S)-2-[[[[[[((1R,2R)-2-氨基环己基]氨基]硫代甲基]氨基]-N-(二苯甲基)-N,3,3-三甲基丁酰胺

(2-硝基苯基)磷酸三酰胺

(2,6-二氯苯基)乙酰氯

(2,3-二甲氧基-5-甲基苯基)硼酸

(1S,2S,3S,5S)-5-叠氮基-3-(苯基甲氧基)-2-[(苯基甲氧基)甲基]环戊醇

(1S,2S,3R,5R)-2-(苄氧基)甲基-6-氧杂双环[3.1.0]己-3-醇

(1-(4-氟苯基)环丙基)甲胺盐酸盐

(1-(3-溴苯基)环丁基)甲胺盐酸盐

(1-(2-氯苯基)环丁基)甲胺盐酸盐

(1-(2-氟苯基)环丙基)甲胺盐酸盐

(1-(2,6-二氟苯基)环丙基)甲胺盐酸盐

(-)-去甲基西布曲明

龙蒿油

龙胆酸钠

龙胆酸叔丁酯

龙胆酸

龙胆紫-d6

龙胆紫