2,8-Dioctyl phenothiazine

中文名称

——

中文别名

——

英文名称

2,8-Dioctyl phenothiazine

英文别名

2,8-dioctyl-10H-phenothiazine

CAS

——

化学式

C28H41NS

mdl

——

分子量

423.7

InChiKey

QYZRFLASALOUKY-UHFFFAOYSA-N

BEILSTEIN

——

EINECS

——

-

物化性质

-

计算性质

-

ADMET

-

安全信息

-

SDS

-

制备方法与用途

-

上下游信息

-

反应信息

-

文献信息

-

表征谱图

-

同类化合物

-

相关功能分类

-

相关结构分类

计算性质

-

辛醇/水分配系数(LogP):11.7

-

重原子数:30

-

可旋转键数:14

-

环数:3.0

-

sp3杂化的碳原子比例:0.57

-

拓扑面积:37.3

-

氢给体数:1

-

氢受体数:2

文献信息

-

PRODUCTION OF TERT-BUTYL ESTERS OF ETHYLENICALLY UNSATURATED CARBOXYLIC ACIDS申请人:BASF SE公开号:US20190002389A1公开(公告)日:2019-01-03A process for continuously preparing the tert-butyl ester of an ethylenically unsaturated carboxylic acid, by a) reacting an ethylenically unsaturated carboxylic acid with isobutene in the presence of an acidic catalyst to give an esterification mixture; b) removing the acidic catalyst; c) removing low-boiling components; and d) supplying a tert-butyl ester-comprising liquid to a distillation apparatus and subjecting it to purifying distillation in the distillation apparatus, where d 1 ) in the distillation apparatus the tert-butyl ester-comprising liquid is separated into a tert-butyl ester-comprising gaseous top product and a carboxylic acid-comprising liquid bottom product; d 2 ) the tert-butyl ester-comprising gaseous top product is at least partly condensed and the condensate is recycled partly as reflux to the distillation apparatus; d 3 ) the carboxylic acid-comprising liquid bottom product is recycled at least partly to step a); d 4 ) carboxylic acid-comprising liquid bottom product is drawn off and passed to a heater; a superheated, liquid recycle stream is taken from the heater; and the superheated recycle stream is let down into the distillatiuon apparatus; and d 5 ) at least in the top region of the distillation apparatus, the distillation apparatus walls in contact with the vapor, at least in sub-regions, are heated and/or thermally insulated. In the course of the process, the separation of the tert-butyl ester from unreacted carboxylic acid is carried on with a particularly low level of accompanying polymerization both of the tert-butyl ester and of the carboxylic acid.一种连续制备乙烯基不饱和羧酸叔丁酯的方法,包括以下步骤:a)在酸性催化剂存在下,将乙烯基不饱和羧酸与异丁烯反应,得到酯化混合物;b)去除酸性催化剂;c)去除低沸点成分;d)将含有叔丁酯的液体供给蒸馏设备,在蒸馏设备中进行纯化蒸馏,其中d1)在蒸馏设备中,将含有叔丁酯的液体分离成含有叔丁酯的气态顶部产品和含有羧酸的液态底部产品;d2)将含有叔丁酯的气态顶部产品至少部分冷凝,所得冷凝物部分作为回流物回收至蒸馏设备;d3)将含有羧酸的液态底部产品至少部分回收至步骤a);d4)将含有羧酸的液态底部产品抽出并通过加热器,从加热器中取出过热的液态回收流,将过热的回收流放入蒸馏设备中;d5)至少在蒸馏设备的顶部区域,与蒸汽接触的蒸馏设备壁面至少在子区域中加热和/或热绝缘。在该过程中,从未反应的羧酸中分离出叔丁酯,伴随的叔丁酯和羧酸的聚合水平特别低。

-

Polymerization inhibitor composition for vinyl aromatic compounds申请人:UNIROYAL CHEMICAL COMPANY, Inc.公开号:EP0325059A2公开(公告)日:1989-07-26Vinyl aromatic compounds are stabilized against polymerization by the addition of an effective amount of a polymerization inhibition composition comprising (a) a phenothiazine compound; and (b) an aryl-substituted phenylenediamine compound. In other aspects, this invention is directed to a vinyl aromatic composition stabilized against polymerization by such polymerication inhibitor composition, as well as to a method of stabilizing a vinyl aromatic composition against polymerization which method comprises adding an effective amount of such polymerization inhibitor composition.

-

Vinyl aromatic compositons stabilized against polymerization申请人:UNIROYAL CHEMICAL COMPANY, Inc.公开号:EP0334500A1公开(公告)日:1989-09-27Vinyl aromatic compounds are stabilized against polymerization by the addition of an effective amount of a polymerization inhibition composition comprising (a) a phenothiazine compound; and (b) an aryl-substituted phenylenediamine compound. In other aspects, this invention is directed to a vinyl aromatic composition stabilized against polymerization by such polymerication inhibitor composition, as well as to a method of stabilizing a vinyl aromatic composition against polymerization which method comprises adding an effective amount of such polymerization inhibitor composition.

-

Polymerization inhibitors for acrylic acids and esters申请人:UNIROYAL CHEMICAL COMPANY, Inc.公开号:EP0522709A2公开(公告)日:1993-01-13This invention is directed to certain N,N'-dinitroso phenylenediamines useful as polymerization inhibitors for acrylic acids and esters thereof. Also disclosed are compositions containing such compounds, and methods for inhibiting polymerization using such compounds and compositions.

-

Preparation of tert-butyl esters of aliphatic carboxylic acids申请人:BASF SE公开号:US10023520B2公开(公告)日:2018-07-17A process for continuously preparing the tert-butyl ester of an aliphatic C1-C4 carboxylic acid comprises: a) the reaction of an aliphatic C1-C4 carboxylic acid with isobutene in the presence of an acidic catalyst to give an esterification mixture (G1); b) the partial evaporation of the esterification mixture (G1), giving a liquid first high boiler phase (SPh1) comprising the acidic catalyst, and a first vapor (B1) comprising tert-butyl ester; c) the fractional condensation of the first vapor (B1) by partially condensing the first vapor (B1) at a first pressure and a first temperature and obtaining a first condensate (K1), partially condensing the uncondensed second vapor (B2) at a second pressure and a second temperature and obtaining a second condensate (K2), the first temperature being 0 to 45° C. below the condensation temperature of the tert-butyl ester at the first pressure and the second temperature being 45 to 80° C. below the condensation temperature of the tert-butyl ester at the second pressure, with the proviso that the second temperature is at least 5° C. below the first temperature; and d) the combination of the first condensate (K1) and the second condensate (K2) and the feeding to a combined workup, and recycling of the third vapor (B3) not condensed at the second temperature into step a). The process allows the preparation of the tert-butyl ester of an aliphatic C1-C4 carboxylic acid by reaction of the carboxylic acid with isobutene, with isolation of unconverted isobutene from the esterification mixture in an energetically favorable manner and with an improved degree of removal.一种连续制备脂肪族 C1-C4 羧酸叔丁酯的工艺包括a) 在酸性催化剂存在下,脂肪族 C1-C4 羧酸与异丁烯反应,生成酯化混合物 (G1); b) 部分蒸发酯化混合物 (G1),生成包含酸性催化剂的液态第一高锅炉相 (SPh1) 和包含叔丁酯的第一蒸汽 (B1);c) 通过在第一压力和第一温度下部分冷凝第一蒸气 (B1) 并得到第一冷凝物 (K1),在第二压力和第二温度下部分冷凝未冷凝的第二蒸气 (B2)并得到第二冷凝物 (K2),第一温度为 0 至 45° C.第一温度低于叔丁酯在第一压力下的冷凝温度 0 至 45°C,第二温度低于叔丁酯在第二压力下的冷凝温度 45 至 80°C,但第二温度至少低于第一温度 5°C;以及 d) 将第一冷凝物(K1)和第二冷凝物(K2)合并,并送入合并工序,将未在第二温度下冷凝的第三蒸汽(B3)回收至步骤 a)。该工艺可以通过羧酸与异丁烯的反应制备脂肪族 C1-C4 羧酸的叔丁酯,并以能量有利的方式从酯化混合物中分离出未转化的异丁烯,同时提高了异丁烯的去除率。

表征谱图

-

氢谱1HNMR

-

质谱MS

-

碳谱13CNMR

-

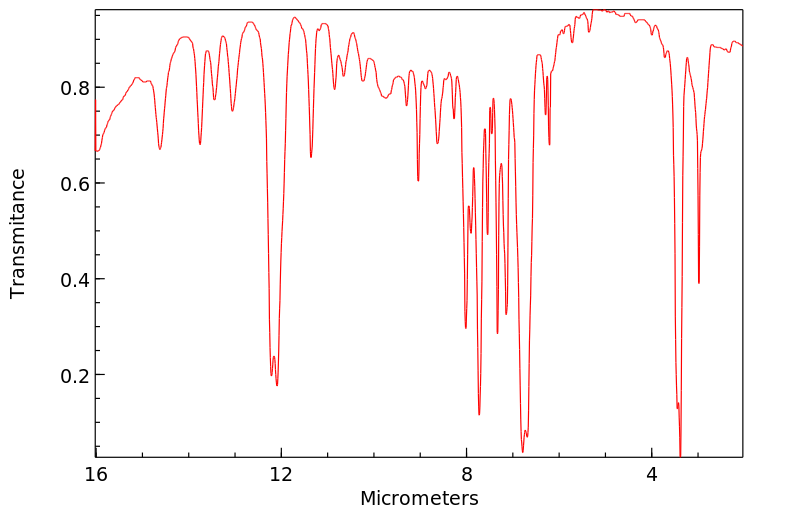

红外IR

-

拉曼Raman

-

峰位数据

-

峰位匹配

-

表征信息

同类化合物

高氟奋乃静

马来酸甲哌丙嗪

马来酸奋乃静

马来酸乙巯拉嗪

锁匹达新

醋酸奋乃静

醋异丙嗪

酒石酸异丁嗪

还原亚甲蓝

达赛马嗪

螺氯丙嗪

莫雷西嗪亚砜

茶氯酸异丙嗪

苹果酸硫乙拉嗪

苯达莫司汀杂质A

苯甲酸2-(2H-1,4-苯并噻嗪-3-基)酰肼

苯甲酸,4-硝基-2-[[3-(三氟甲基)苯基]氨基]-

苯甲酰基氧基甲基-[3-(2-氯吩噻嗪-10-基)丙基]-二甲基氯化铵

苯并噻嗪-5-氧化

苯并噻嗪-5-正离子,3,7-二(二甲氨基)-4-碘-,氯化

苯并噻嗪,10-(2-(4-丙基-1-哌嗪基)丙基)-

苯并[b]吩噻嗪-12-基(苯基)甲酮

苯并[a]吩噻嗪-5-酮

苯丙嗪

苄酰基无色亚甲基兰

芬诺宁

芬乙嗪

舒多昔康

羟乙哌氟嗪

美索哒嗪

美索丙嗪

美洛昔康钾盐

美洛昔康钠

美洛昔康-d3

美洛昔康

美托奋乃酯

美托哌丙嗪酸

美托哌丙嗪

美托咪嗪-d6

美喹他嗪亚砜

美喹他嗪

磺达嗪

硫堇(劳氏紫)

硫利达嗪杂质A(EP)

硫利达嗪N-氧化物

硫利达嗪-5-亚砜

硫利达嗪

硫代哒嗪-d35-亚砜

硫丙拉嗪

盐酸诺美丙嗪